Fire detector for injection moulding workshop

A technology for fire detectors and workshops, applied in fire alarms, fire alarms that rely on smoke/gas effects, instruments, etc., can solve the problems of dismantling the body, large equipment size, and inability to install in a specific location. Achieve the effect of saving installation time, simple external structure, and avoiding irreparable maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

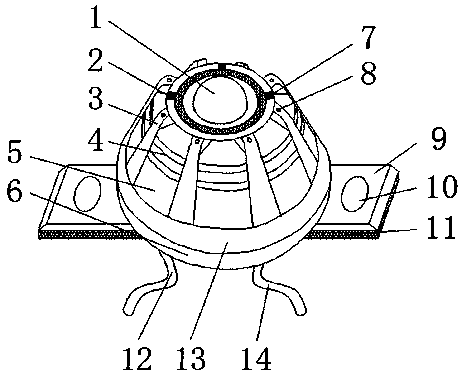

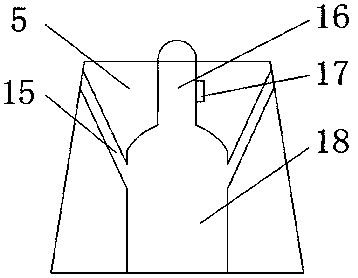

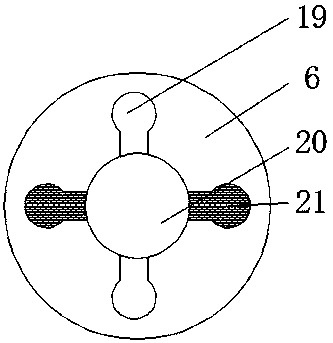

[0021] refer to Figure 1-3 , a fire detector for an injection molding workshop, including a rotating housing 5, a fixed strip 3 and a body 13, the body 13 is composed of a rotating housing 5, a fixed bottom housing 6 and a mounting plate 9, and a light ring belt is embedded in the upper end of the rotating housing 5 2. A smoke detection head 1 is fixed at the center of the light ring 2, and the outer wall of the light ring 2 is equipped with a speaker 7, and when the data detected by the detection head exceeds the preset value, the whistle will sound , there are three loudspeaker ports 7, and the three loudspeaker ports 7 are evenly distributed on the upper surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com