Feeder and part feeding device

A feeder and parts technology, which is applied in the field of feeders and parts supply devices, can solve the problems of reduced parts conveying density and achieve the effect of increasing the supply speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

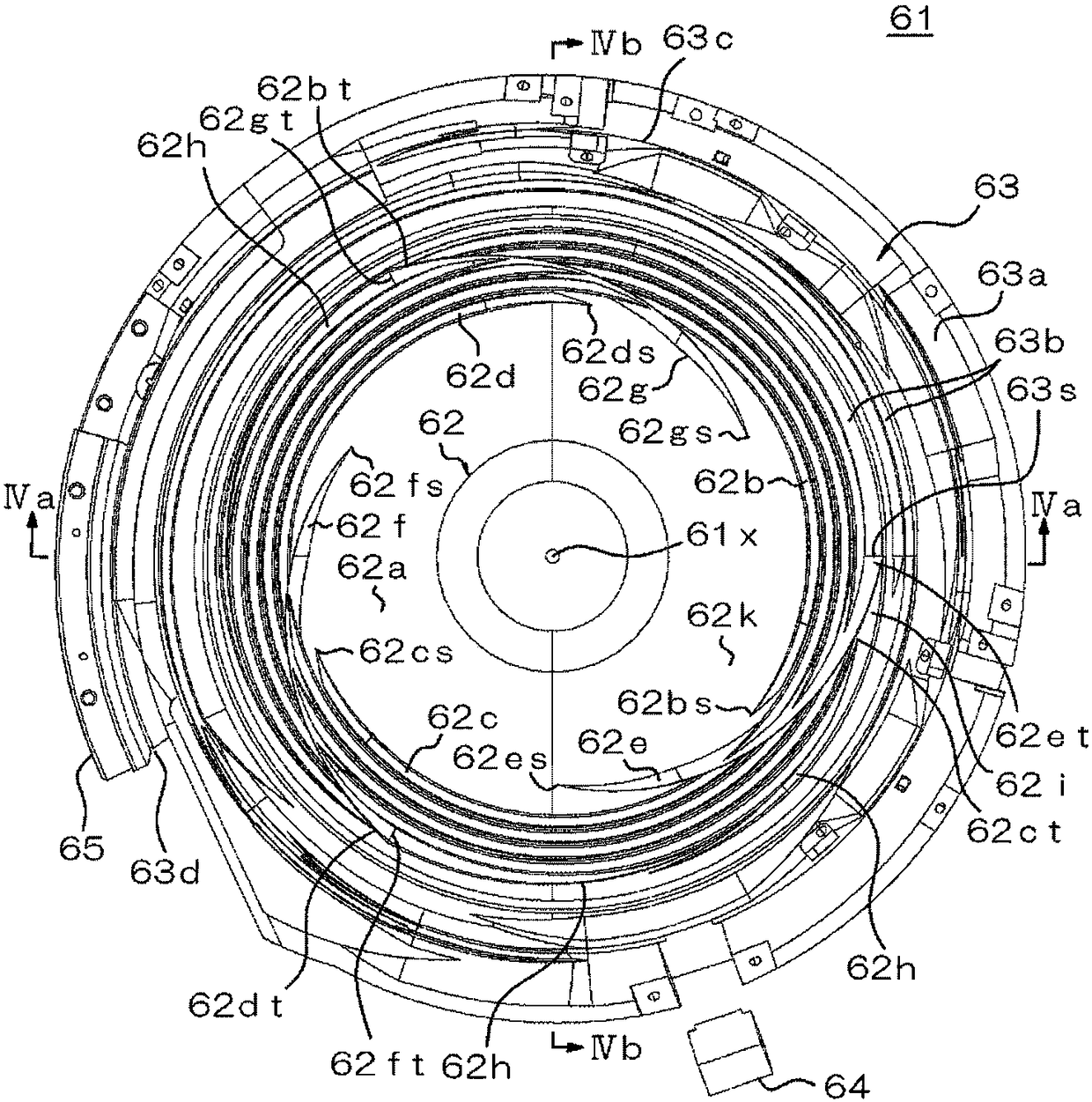

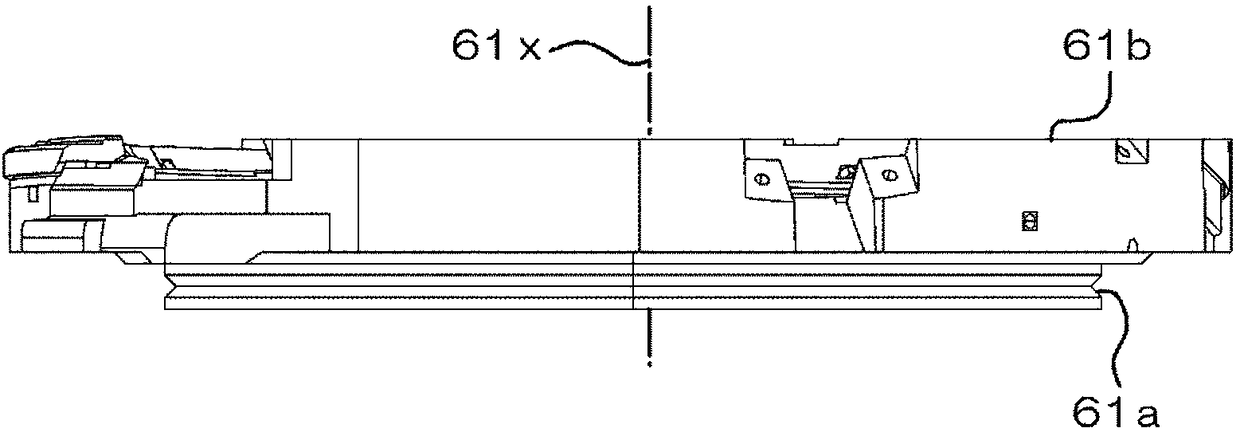

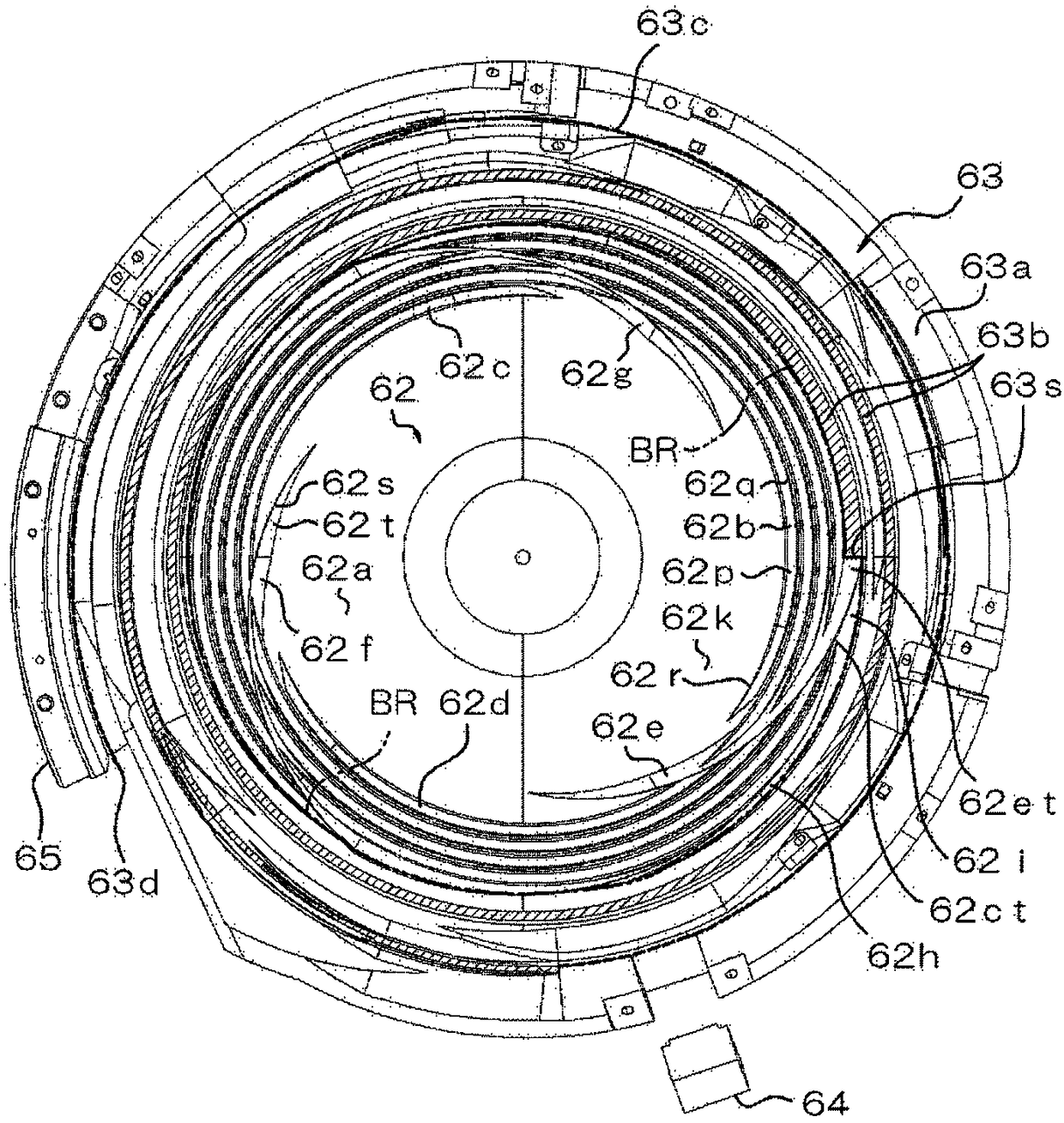

[0058] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. First, refer to Figure 1 to image 3 The shape and structure of the conveying body mounted in the embodiment of the feeder according to the present invention, that is, the parts container will be described. In addition, in the description of the following embodiment, the structure of the feeder other than the illustrated components container is considered to be the general structure which mounts the components container on the conventional rotary vibration machine as shown in FIG. 6. In addition, the structure of the parts supply apparatus including a feeder is the same as above. Here, descriptions of generally employable configurations as described above are omitted.

[0059] The parts container 61 according to the embodiment of the present invention can be integrally provided using metals such as aluminum and an aluminum alloy, or other materials. However, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com