Round barrel type pipe-type heating furnace

A tubular heating furnace, cylindrical technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as uneven heat intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

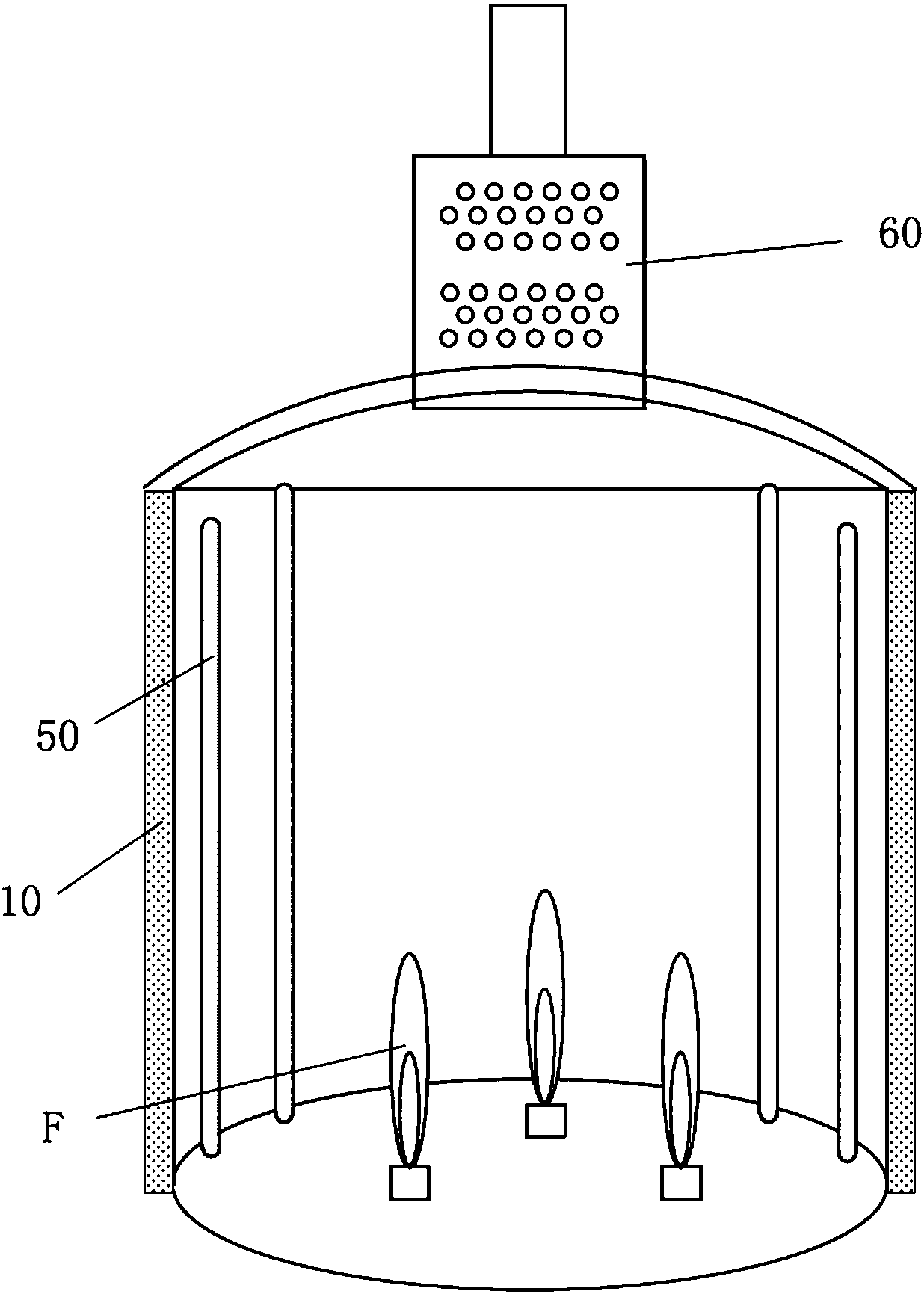

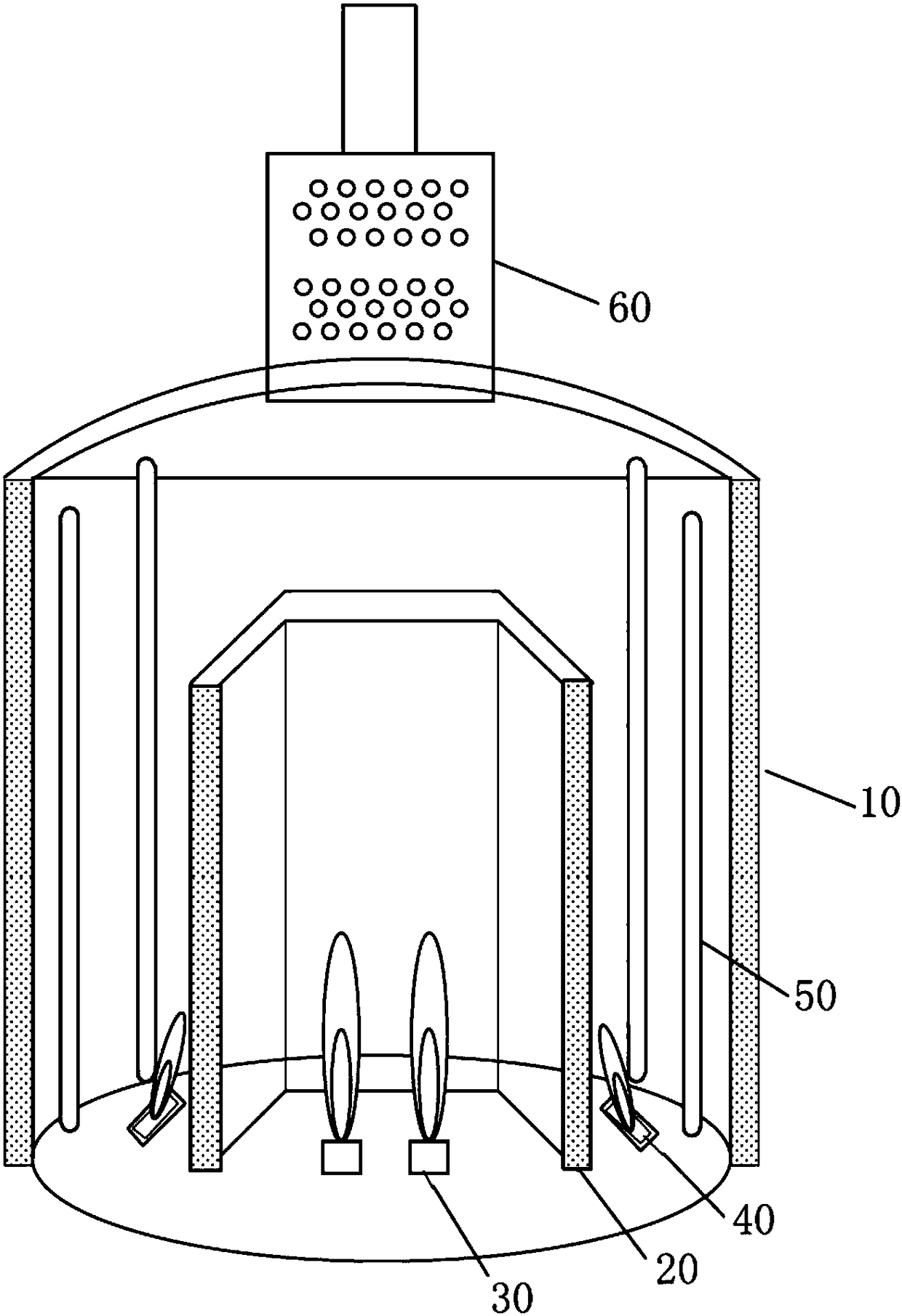

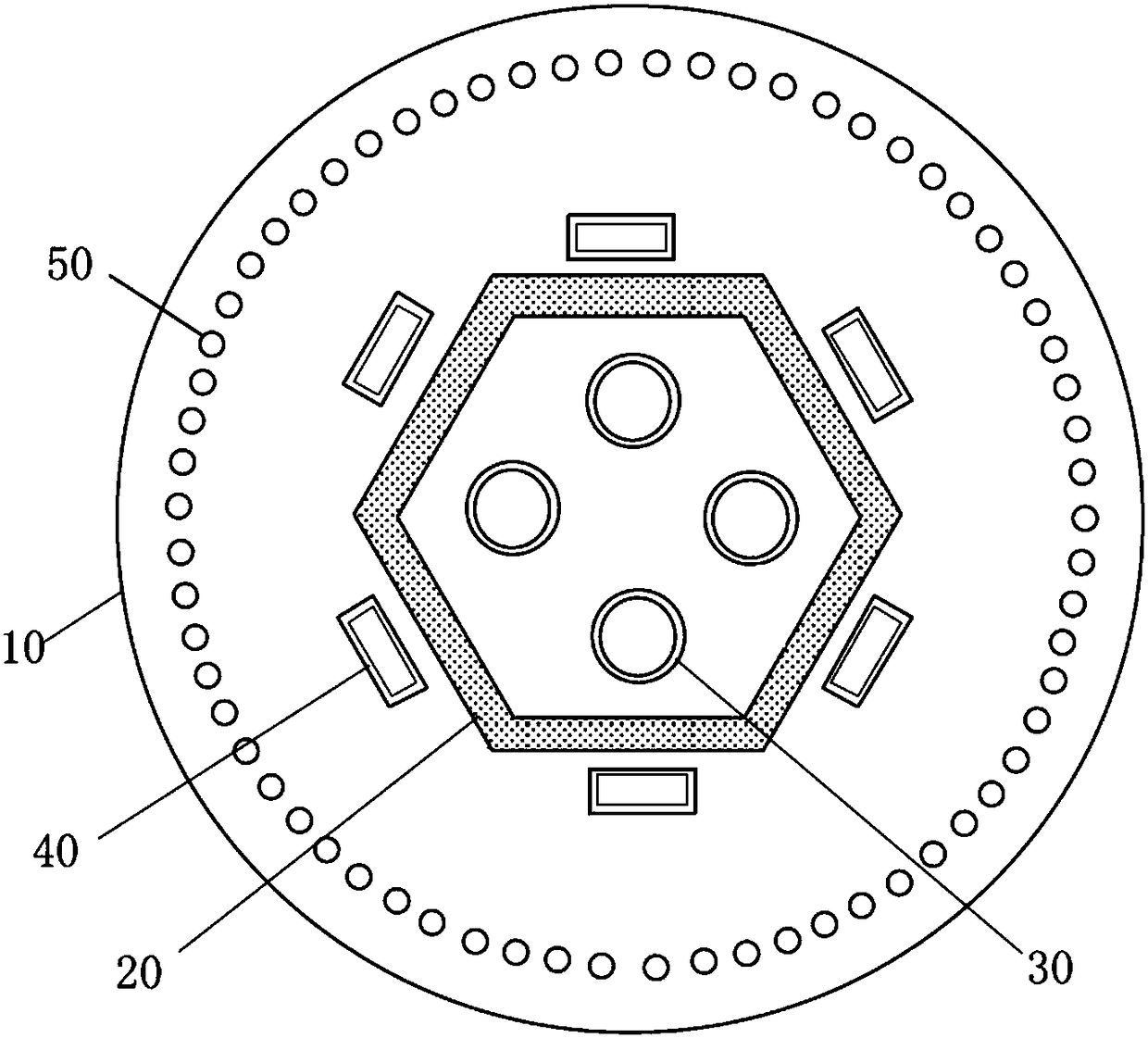

Embodiment 1

[0041] The radiation chamber 10 is cylindrical, with a diameter of φ7600mm, the height of the radiation chamber 10 is 13m, the length of the first furnace tube 50 is 12m, and the outer diameter is φ168mm. The first furnace tubes 50 are arranged in a single row at equal intervals; φ152mm, length 4.0m, 18 rows of second furnace tubes. The first burner 30 is a circular burner, and the total heat load accounts for 70% of the calorific value of the whole furnace; the second burner 40 is a wall burner, and the total heat load accounts for 30% of the calorific value of the whole furnace; The cross-section is a regular hexagon, the diameter of the circumscribed circle is 3.0m, and the height of the middle furnace wall 20 is 2.0m.

Embodiment 2

[0043] A structure similar to that of Embodiment 1 is adopted, except that the cross-section of the middle furnace wall 20 is circular. The middle furnace wall 20 has a diameter of 3.5m and a height of 2.0m. The total heat load of the first burner 30 accounts for 80% of the calorific value of the entire furnace, and the total heat load of the second burner 40 accounts for 20% of the calorific value of the entire furnace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com