Stand pipe square box furnace

A riser tube and square box technology, which is applied in the field of riser tube square box furnaces, can solve the problems such as inability to flexibly adjust the thermal strength of the furnace tube and uneven thermal strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

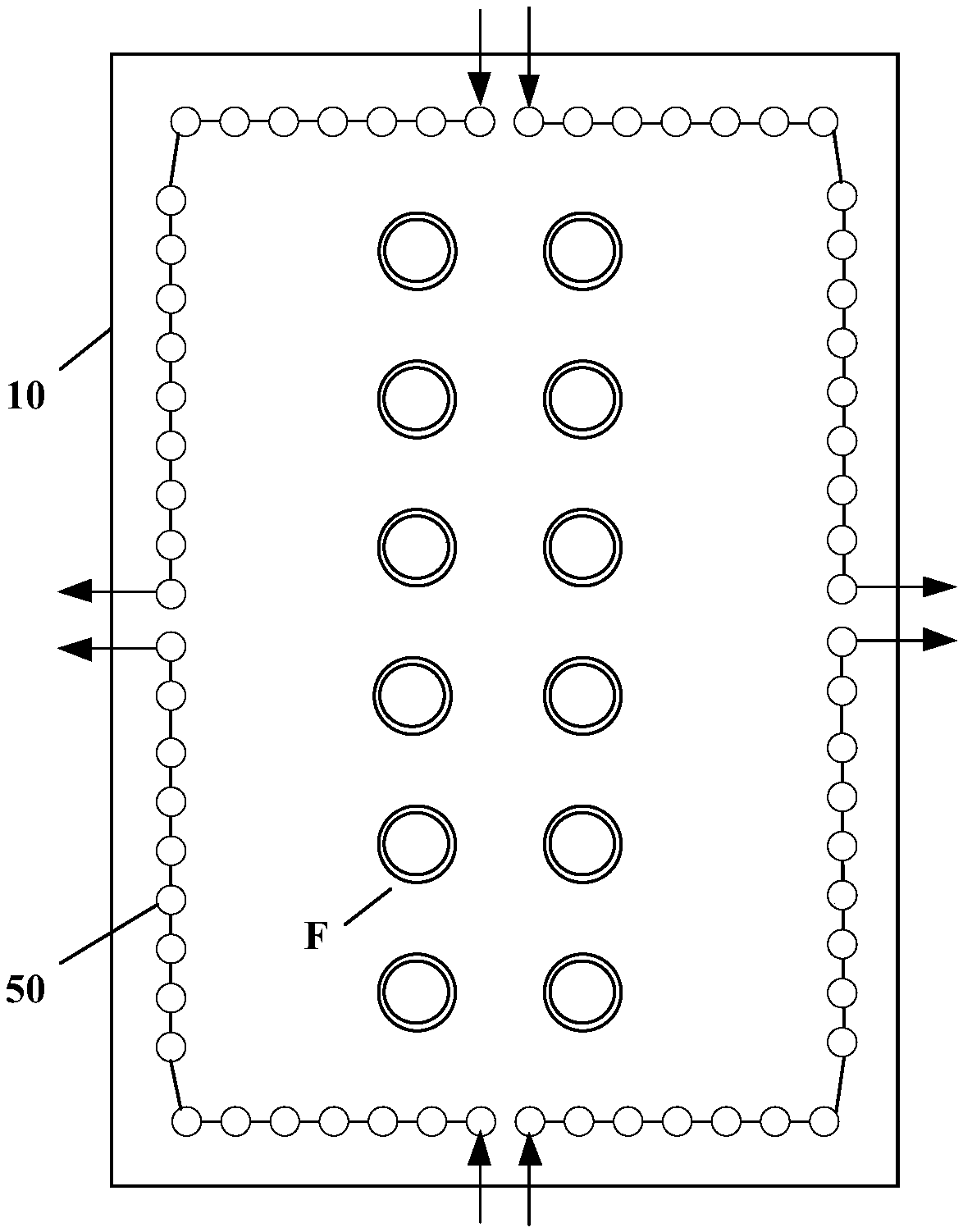

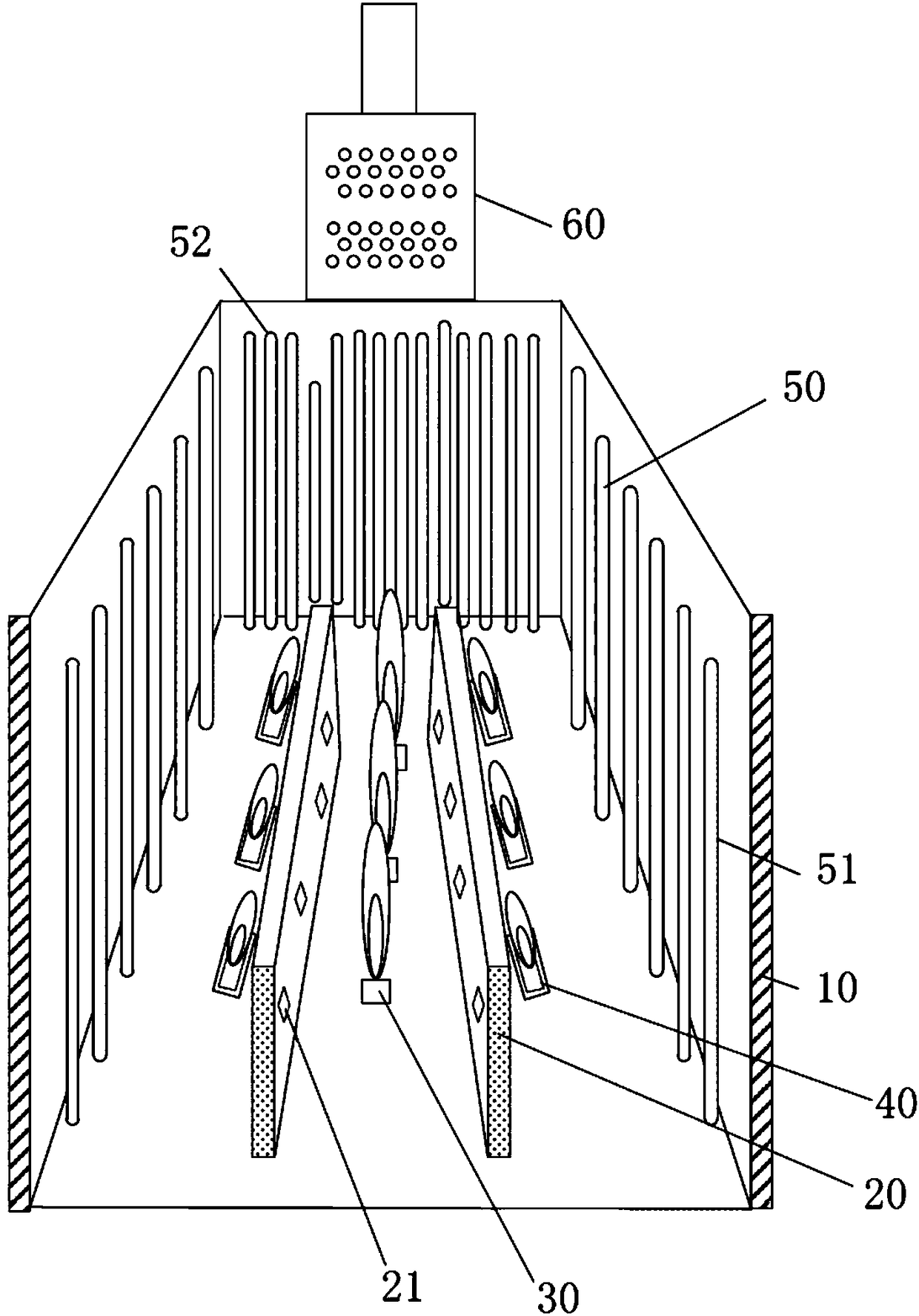

[0045] Such as image 3 As shown, the cross-section of the radiation chamber 10 is rectangular, the size is 5m×5.5m, the height of the radiation chamber 10 is 13m, the length of the first furnace tube 51 is 12m, and the outer diameter φ152mm, there are 36 pieces in total; the second furnace tube 52 The length is 12m, the outer diameter is φ152mm, and there are 28 pieces in total. The first furnace tube 51 and the second furnace tube 52 form a square annular area S, the first furnace tube 51 and the second furnace tube 52 are arranged in a single row at equal intervals, the distance between the furnace tubes is 304 mm, and 16 rows of the first furnace tube are arranged in the convection chamber 60. Three furnace tubes, the outer diameter of each third furnace tube is φ152mm, the length is 5m, the height of the middle furnace wall 20 is 2m, and the heat load of the first burner 30 accounts for 80% of the calorific value of the vertical tube square box furnace, The heat load of ...

Embodiment 2

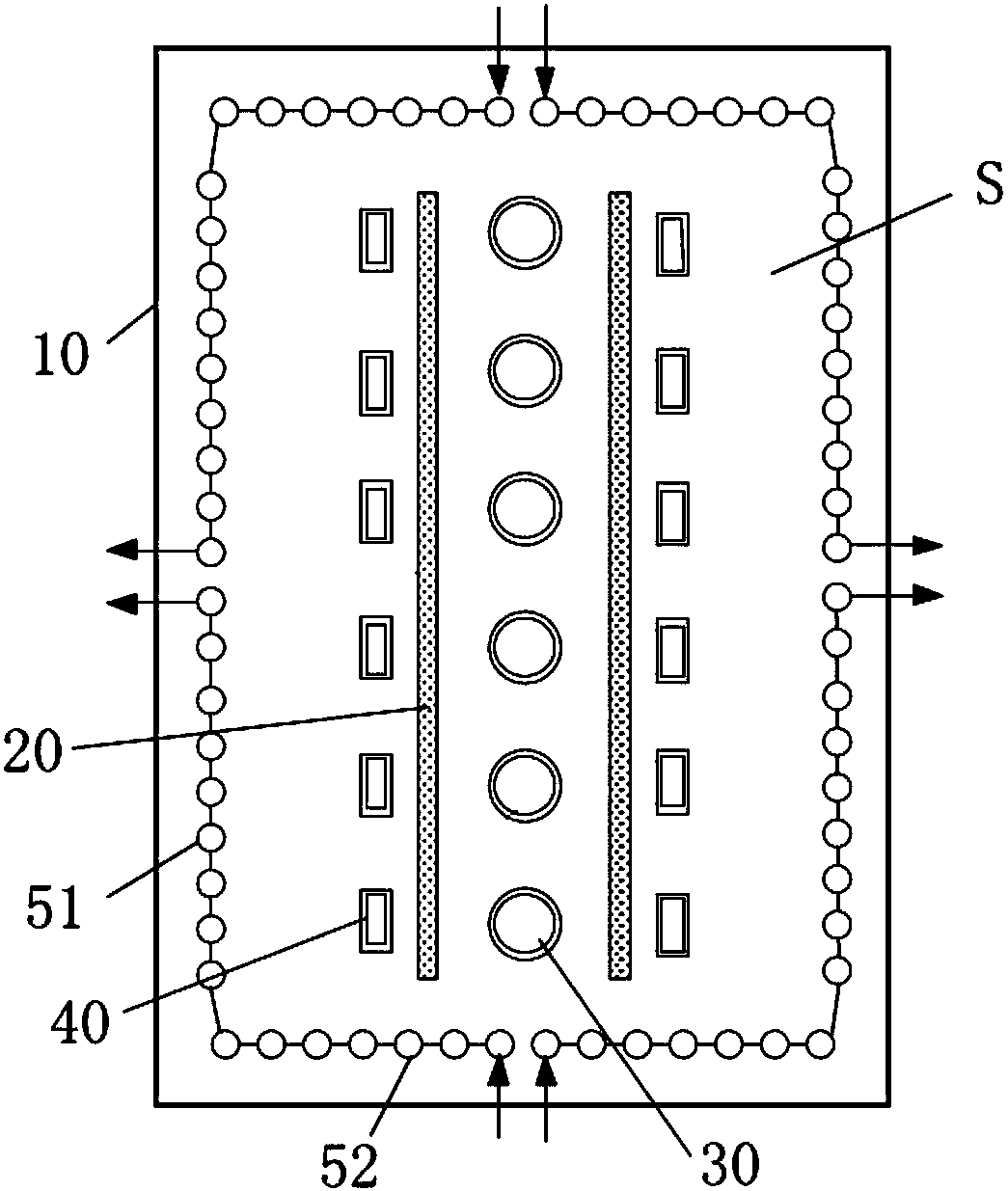

[0047] Adopt the structure similar to embodiment 1, the difference is that, as Figure 4 As shown, the cross-section of the radiation chamber 10 is that the radiation furnace tubes 50 of 13m×6m are arranged into two square annular regions S, the height of the radiation chamber 10 is 16m, the length of the first furnace tube 51 is 15m, and the second furnace tube 52 Length 11m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com