Cylindrical tube heating furnace

A tubular heating furnace, cylindrical technology, applied in the field of cylindrical tubular heating furnace, can solve the problem of low space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

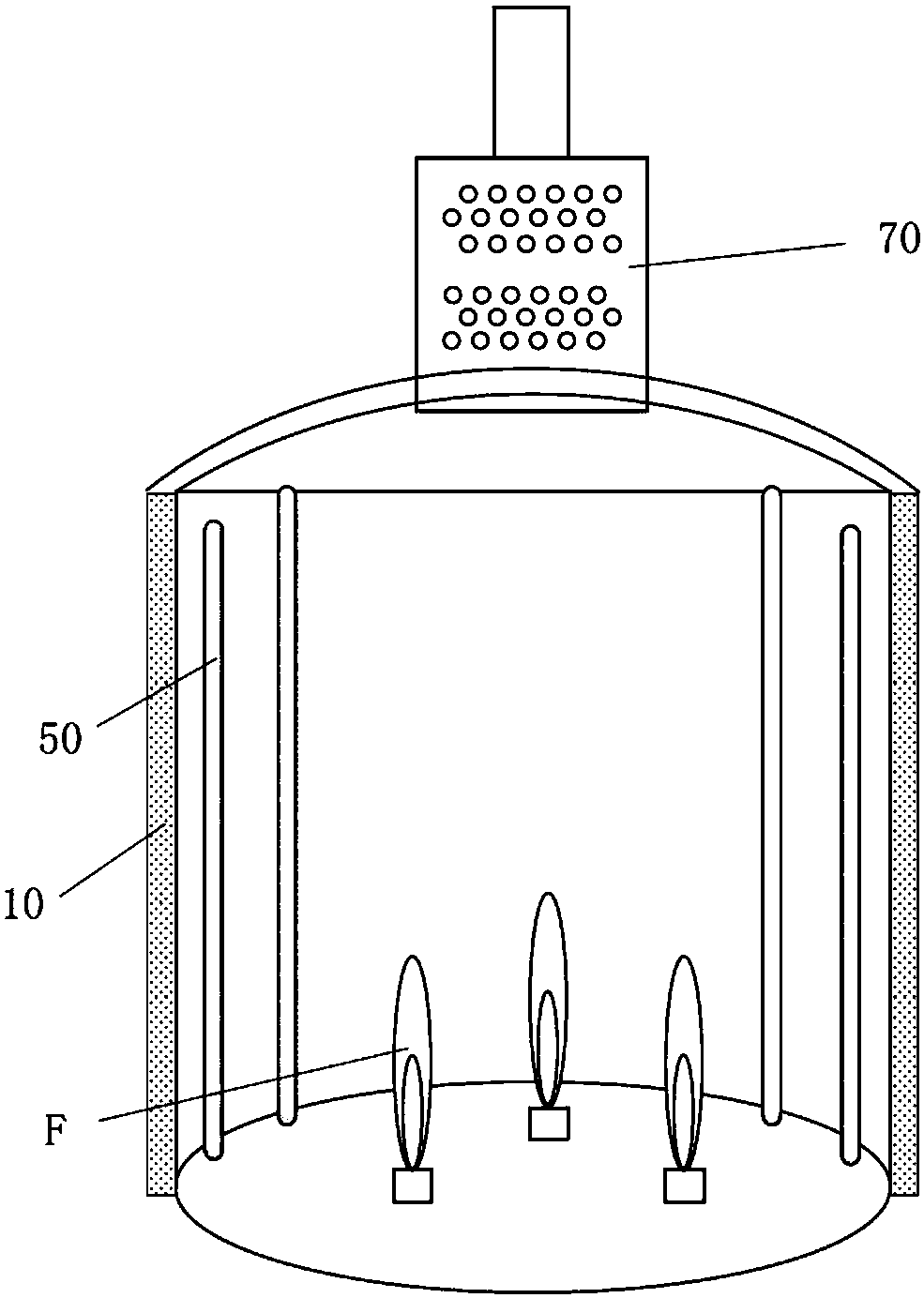

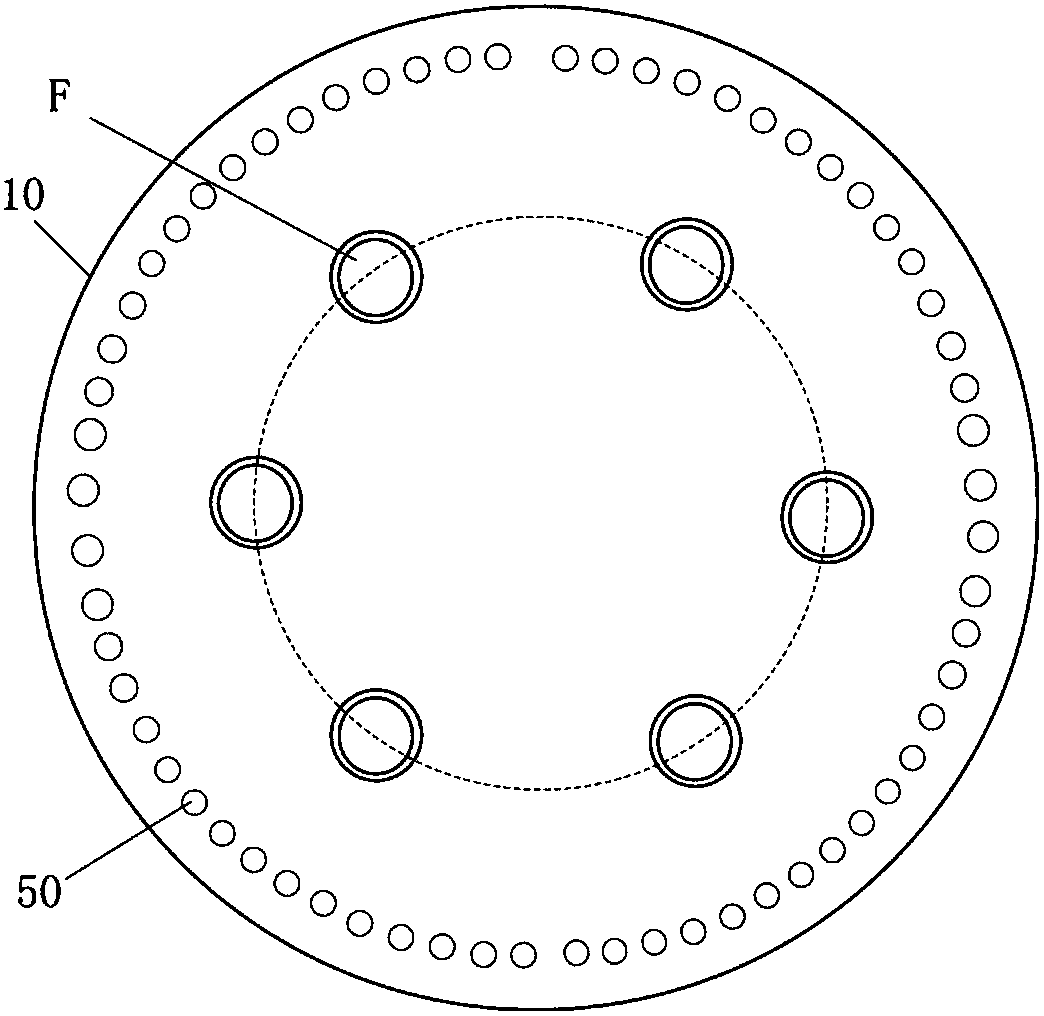

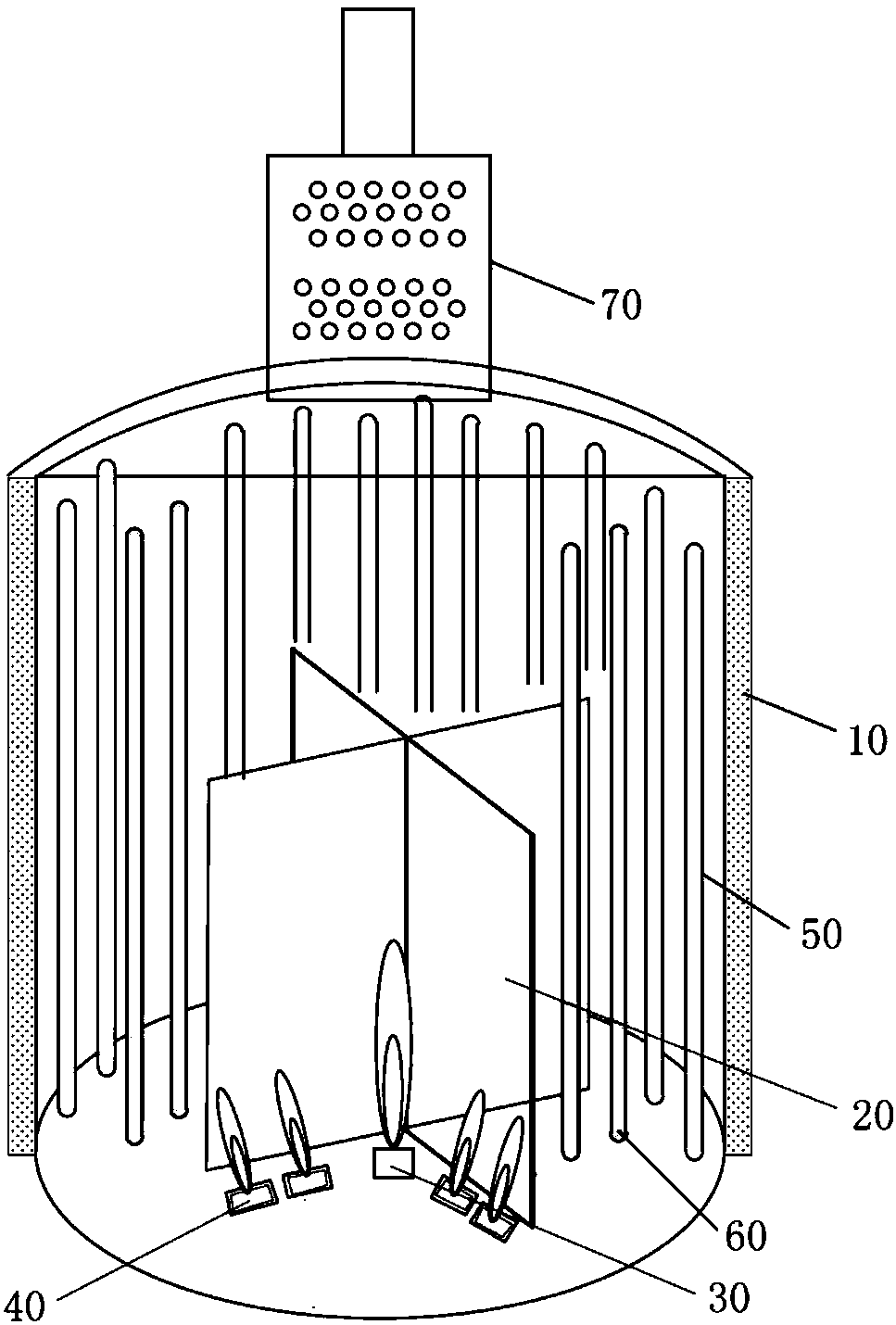

[0039] The structure of the cylindrical tubular heating furnace is as follows: image 3 and Figure 4 shown. The radiation chamber 10 is cylindrical, with a diameter of φ7650mm. The height of the radiation chamber 10 is 15m. The first furnace tube 50 and the second furnace tube 60 have the same specifications, the length is 14m, and the outer diameter is φ168mm. There are 64 vertically arranged furnace tubes. There are 50 first furnace tubes and 16 second furnace tubes 60; the third furnace tubes have an outer diameter of φ152mm and a length of 4.0m, and there are 18 rows of third furnace tubes in total. The height of the middle furnace wall 20 is 2.5m, and the length of the wall body 21 is 2.5m. The space in the radiation chamber 10 is equally divided into 4 heating zones S. The first burner 30 is a circular burner, and the total heat load accounts for the whole 80% of the calorific value of the furnace, the second burner 40 is a burner attached to the wall, and the total h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com