A structure-integrated hydrogenation device

A hydrogenation device, an integrated technology, is applied in the fields of hydrotreating process, petroleum industry, processing of hydrocarbon oil, etc., which can solve the problems of low heating efficiency, high one-time investment cost, large floor space and heat dissipation area, etc. To achieve the effect of reliable principle, reasonable and compact overall arrangement of the device, and reduced floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

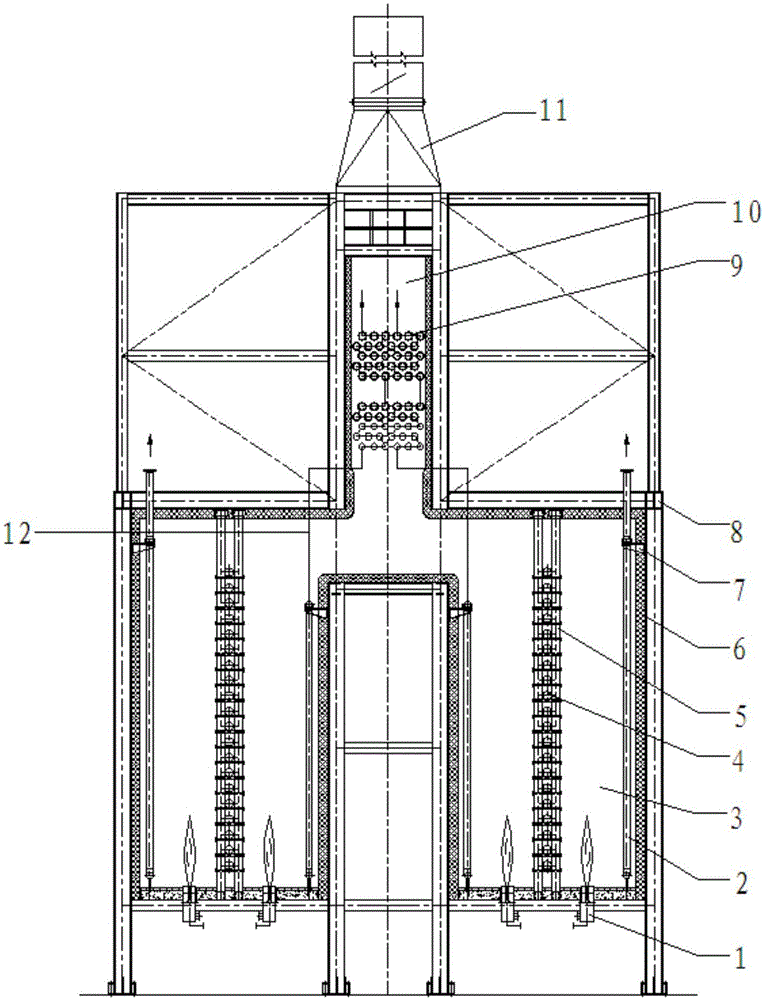

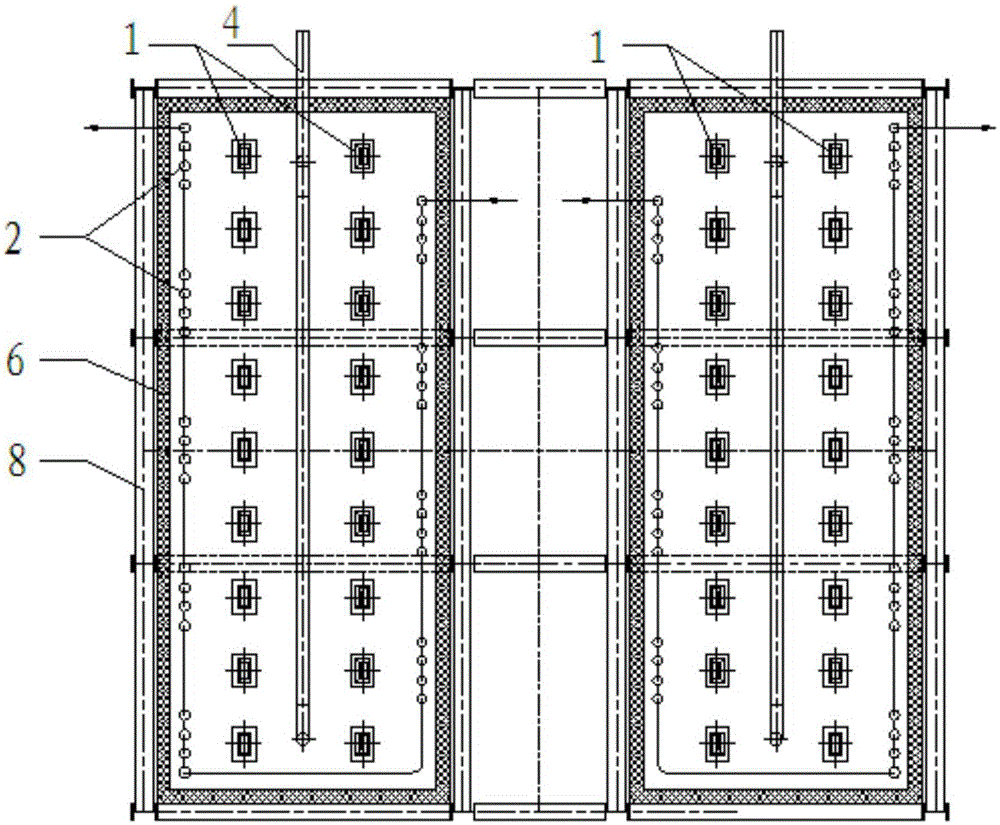

[0012] The main structure of the structure-integrated hydrogenation device involved in this embodiment includes a burner 1, a radiation furnace tube 2 of a reboiler at the bottom of a fractionation tower, a radiation chamber 3, a radiation furnace tube 4 of a reaction feeding furnace, and a radiation furnace tube of a reaction feeding furnace Pipe frame 5, lining 6, fractionation tower bottom reboiler radiant furnace tube hook 7, steel structure frame 8, fractionation tower bottom reboiler convection furnace tube 9, convection chamber 10, chimney 11 and oil transfer line 12, inner space The inner middle and lower ends of the overall hydrogenation device with a three-dimensional structure are separated to form 2-8 radiation chambers 3, and the central vertical direction of the radiation chamber 3 is equipped with a tube frame 5 for the radiation furnace tube of the reaction feeding furnace, and the tube rack 5 for the radiation furnace tube of the reaction feeding furnace Interc...

Embodiment 2

[0016] The structure-integrated hydrogenation device involved in this embodiment provides a further preferred technical solution on the same basis as in Embodiment 1: the radiation furnace tubes 2 of the reboiler furnace at the bottom of the fractionation tower on both sides of the radiation chamber 3 can be separated by one The burners 1 are evenly arranged, so that the radiant furnace tube 2 of the reboiler bottom of the fractionating tower mainly receives the radiant heat from the nearest burner 1, so as to realize the flexible and convenient adjustment of the medium in the radiant furnace tube 2 of the reboiler bottom of the fractionating tower absorbed heat load.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com