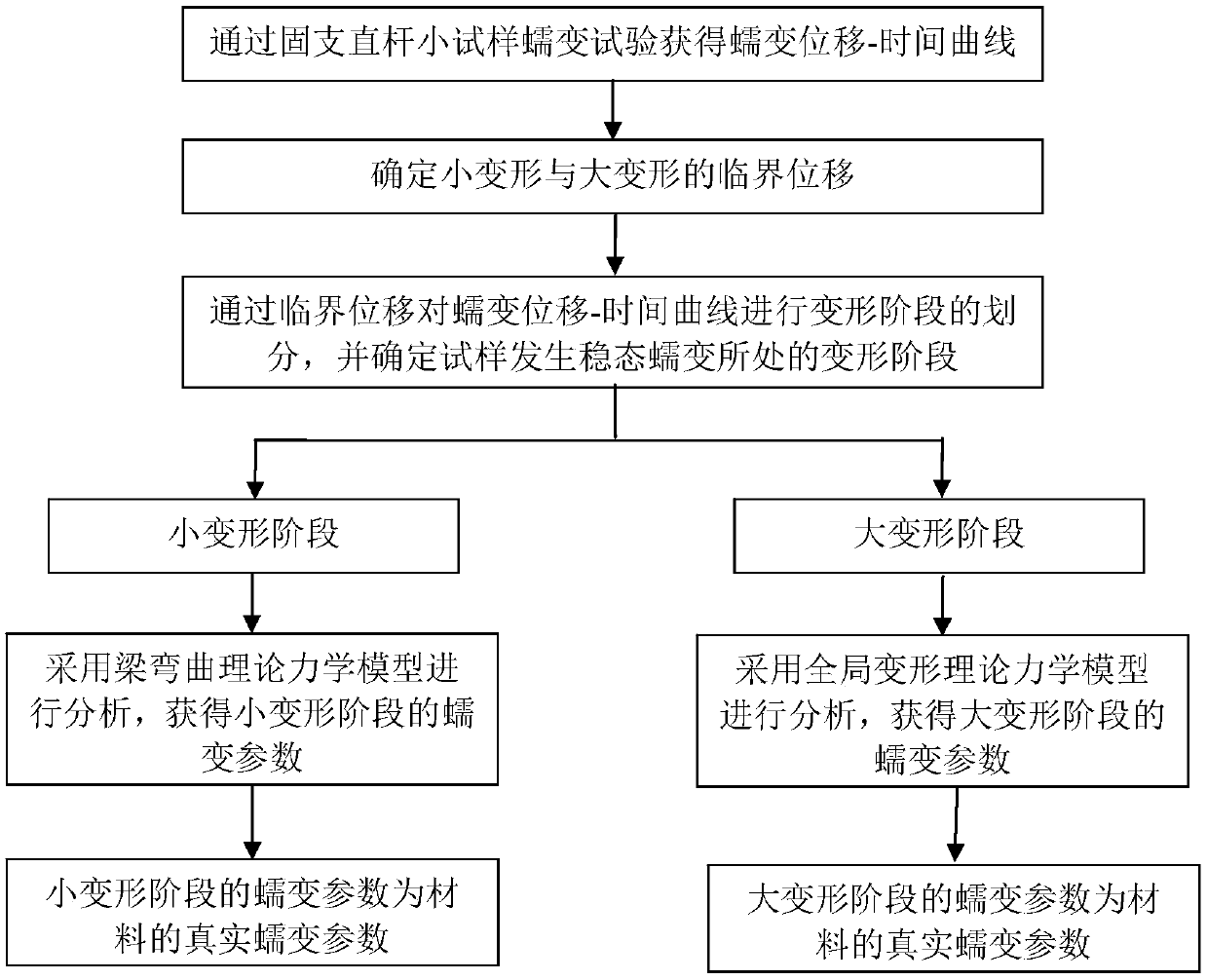

Method for determining creep parameter of material by fixed straight bar small specimen creep test

A creep test, small sample technology, applied in the application of stable tension/pressure test material strength, electrical digital data processing, special data processing applications, etc., can solve the problem of inaccurate determination of material creep parameters, etc. Accurate creep parameters and good correlation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0072] Embodiment: The material is A7N01 aluminum alloy, and the test temperature of the small straight rod sample fixedly supported is 380°C. The process of using the method of the present invention to determine the creep parameters of A7N01 aluminum alloy is as follows:

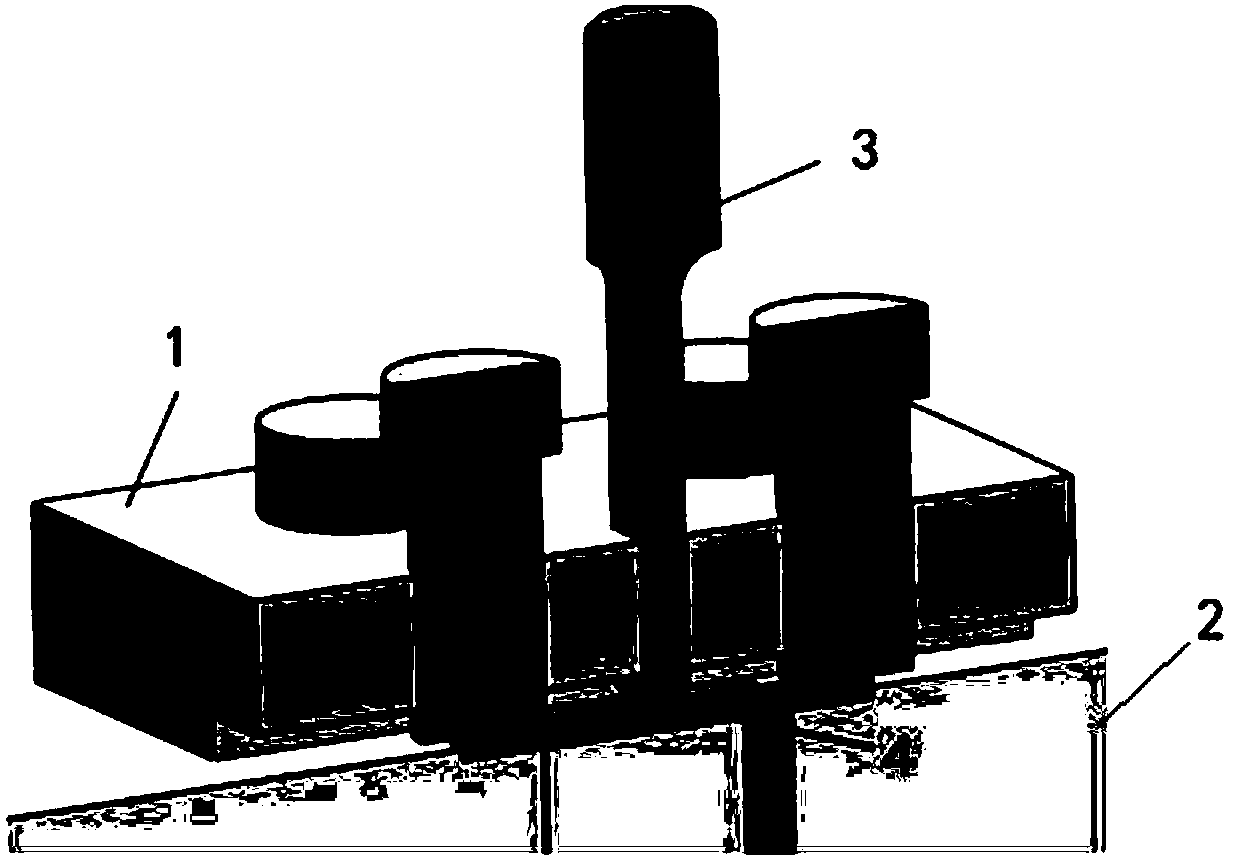

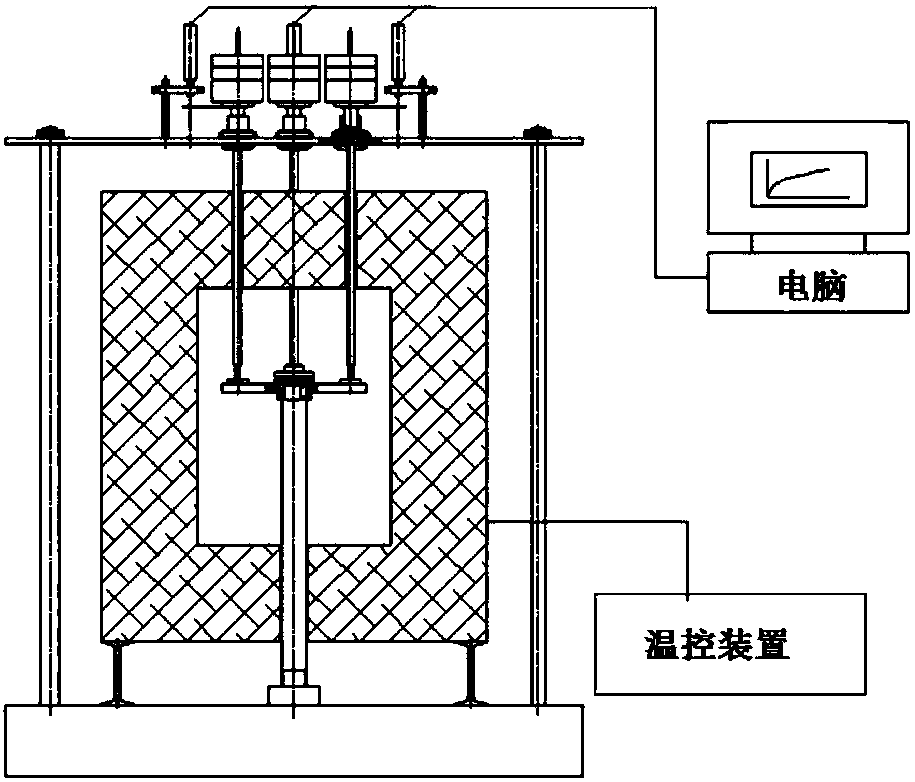

[0073] 1. Take materials from A7N01 aluminum alloy, and make a small straight rod sample of A7N01 aluminum alloy, such as figure 2 , fix the two ends of the small straight rod sample 4 with the upper mold 1 of the fixture, and press the lower end of the indenter 3 to press the middle area of the straight rod small sample 4, and conduct creep tests on A7N01 aluminum alloy with different creep loads at 380°C , and after the test, obtain and record the creep displacement-time curve of the straight bar specimen, such as Figure 4 shown.

[0074] 2. Through the error function, combined with the size of the test device, it is determined that the critical displacement of the sample for small deformation and la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com