Connector

A connector and ground connection technology, which is applied in the connection of rods, connecting members, couplings, etc., can solve the problems of device damage and not being used to disassemble the connecting device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

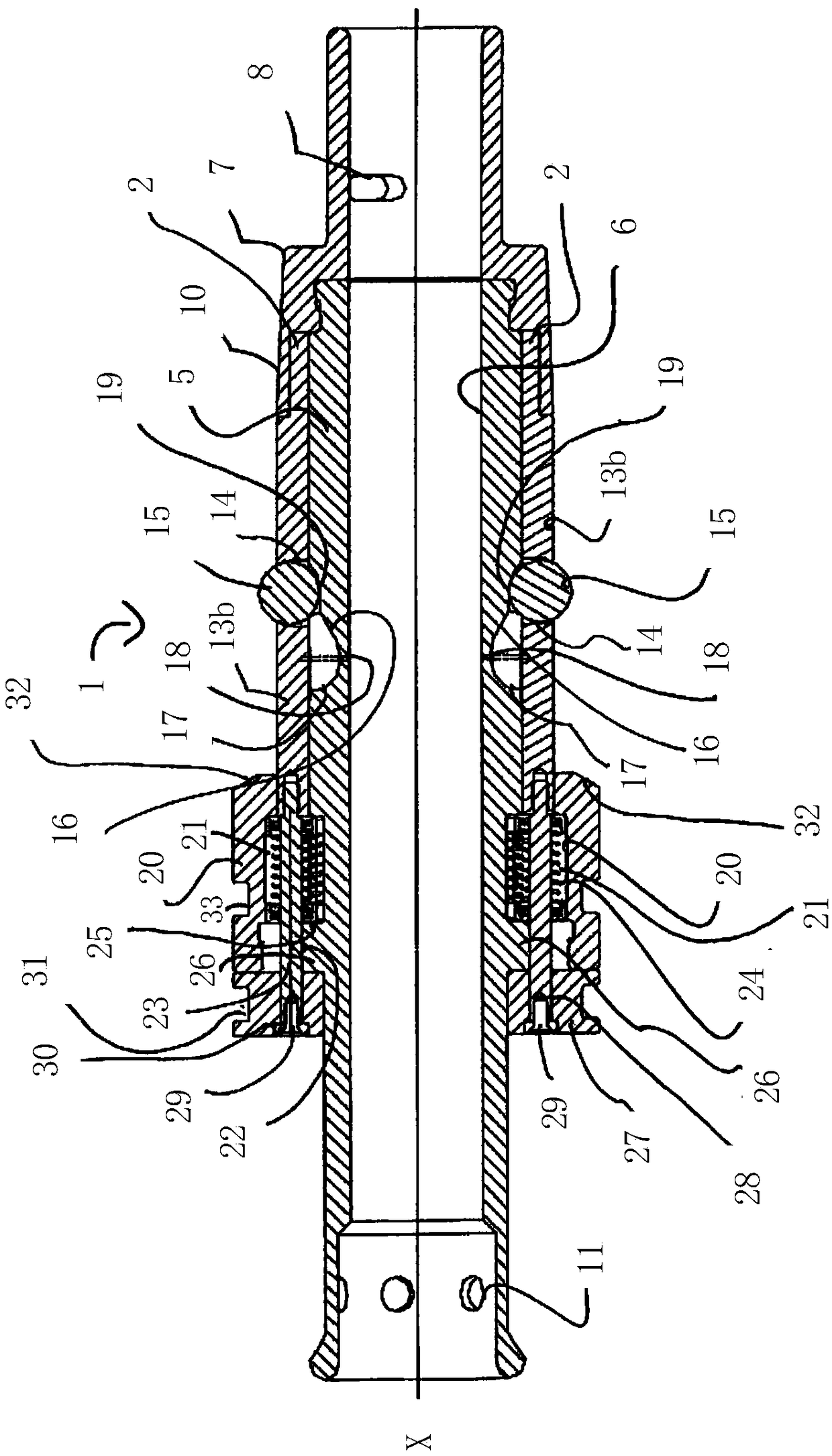

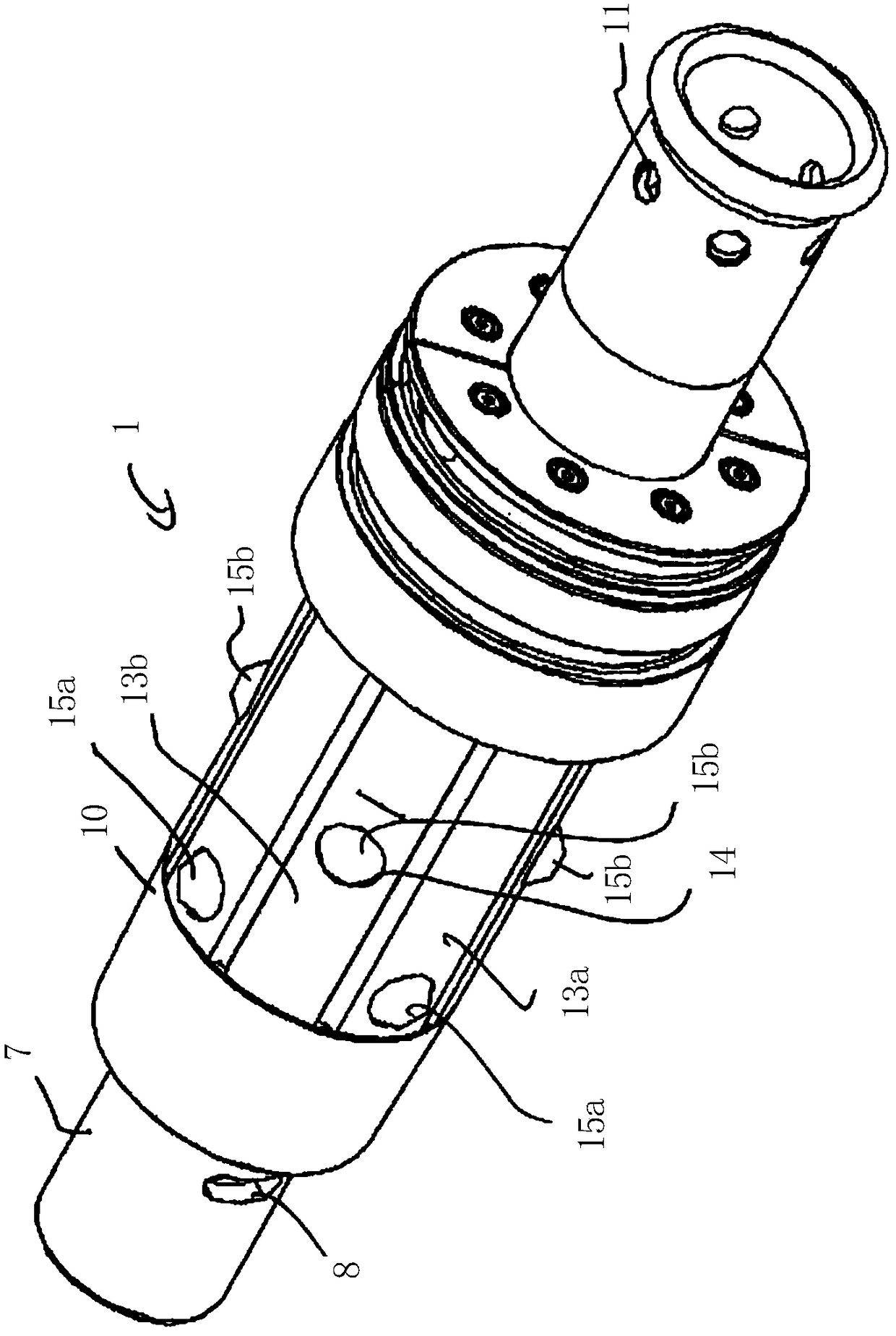

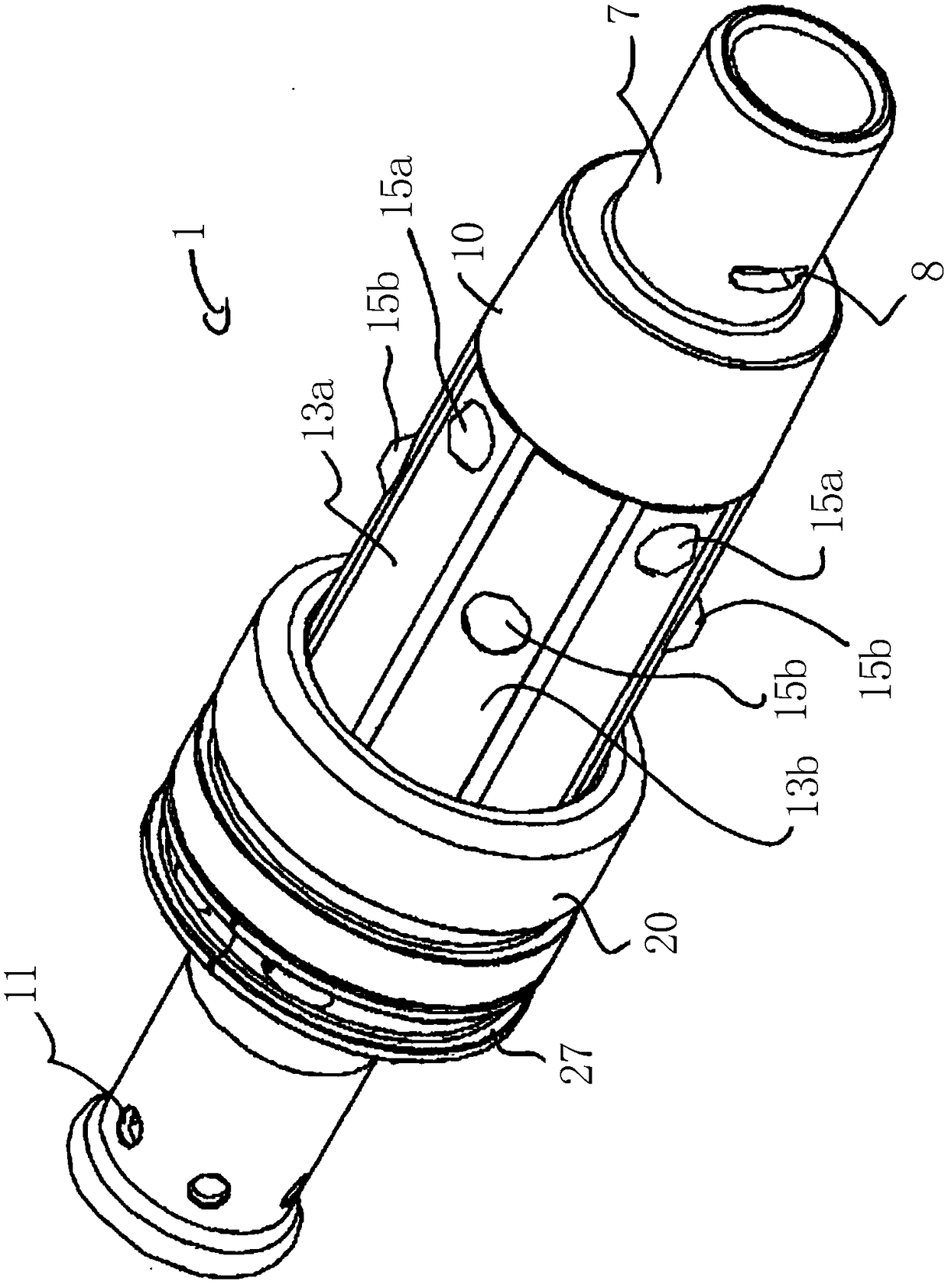

[0090] refer to Figure 1 to Figure 12 , shows a first embodiment of a subsea connector 1 for connecting a cable (not shown) to a support column 3 of a wind turbine generator (such as Figure 4-Figure 7 shown).

[0091] The connector 1 is a male part arranged to be inserted into a female part in the form of a hole 4 extending through the support post 3 at an oblique angle. In an alternative (not shown) the connector may extend into a specially adapted J-tube formed behind (inwardly) the guide cone with a flange acting as the bore.

[0092] The connector 1 comprises a hollow load-bearing mandrel 5 through which a cylindrical bore 6 extends axially along the main (longitudinal) axis X of the connector 1 . The hole 6 is intended to accommodate said cable (not shown) so that the connector 1 can connect said cable (not shown) to the support column 3 . Those skilled in the art will appreciate that by varying the size of the hole 6 other subsea elements (eg risers or umbilicals) c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com