A six-degree-of-freedom compliant parallel robot system with large load

A robotic system and a degree of freedom technology, applied in the field of manipulators, which can solve the problems of tension but not compression, compliant hinge tension but not compression, flexion and instability of compliant hinge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

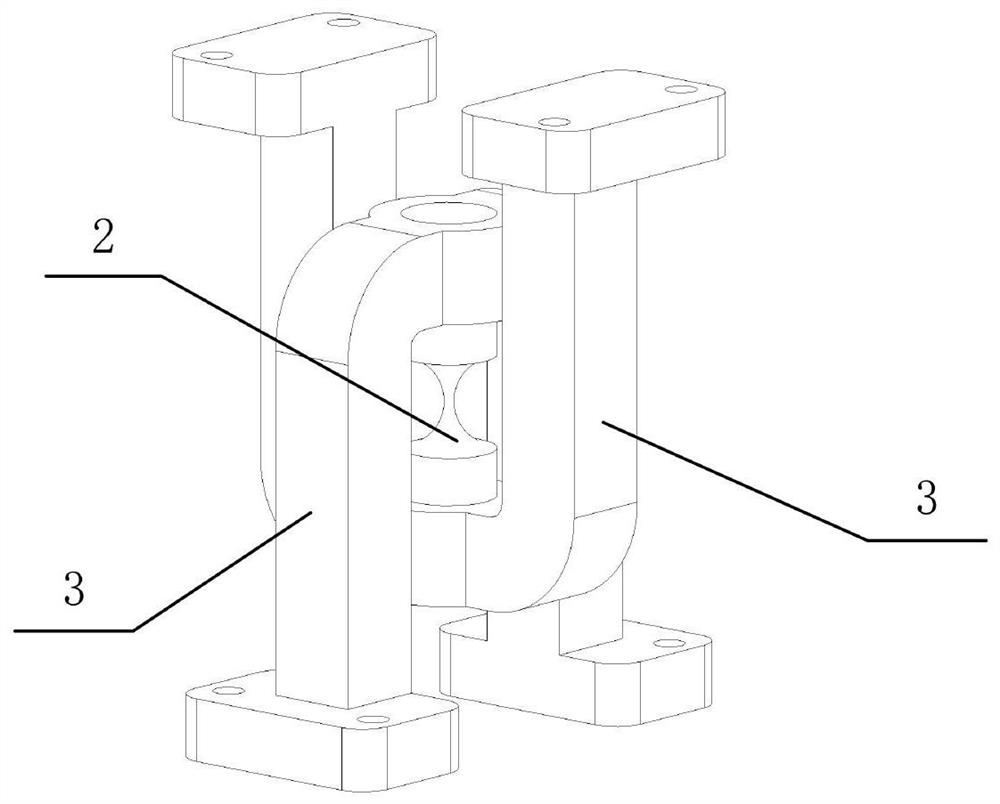

[0031] In the present invention, a force steering component is formed by combining two facing U-shaped pieces and a compliant ball hinge, so that the compliant hinge can bear axial tension during the working process and avoid buckling deformation caused by pressure, so that the large load has six degrees of freedom The compliant parallel robot system can not only meet the micron-level precision requirements that traditional six-degree-of-freedom mechanisms cannot achieve, but also solve the instability problem of general six-degree-of-freedom compliant parallel robot mechanisms under heavy loads.

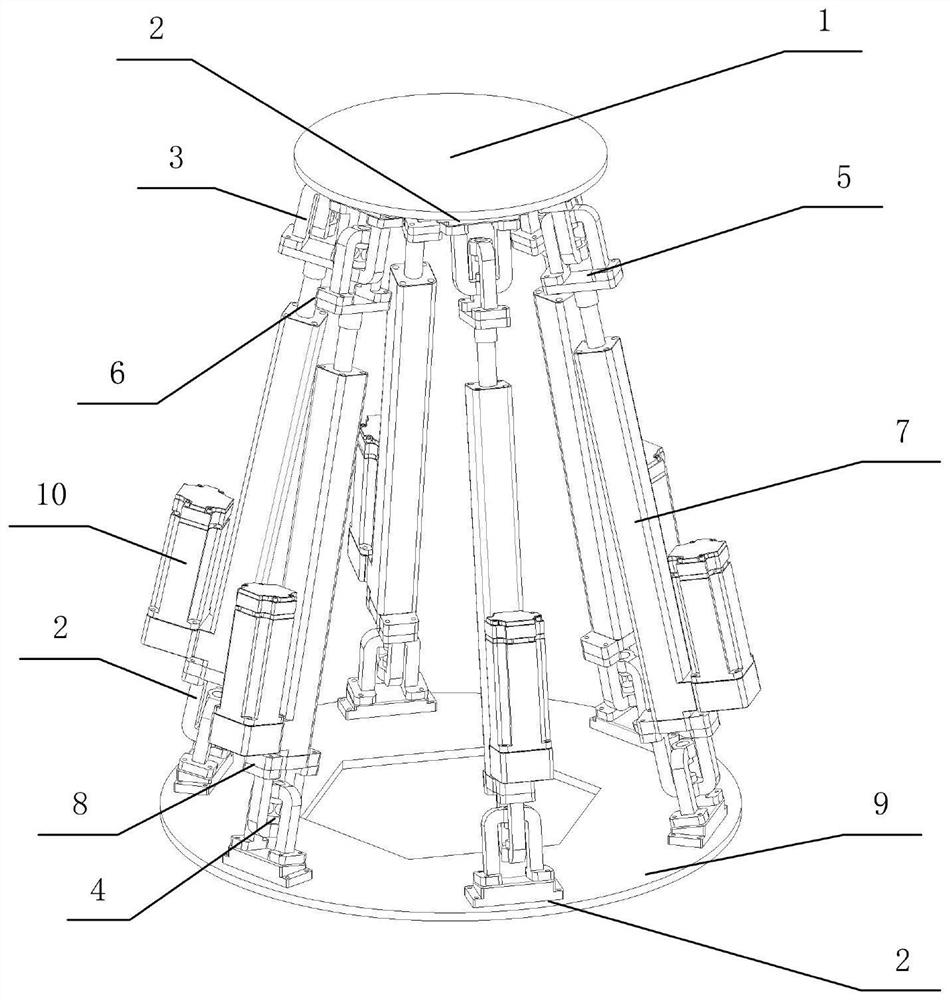

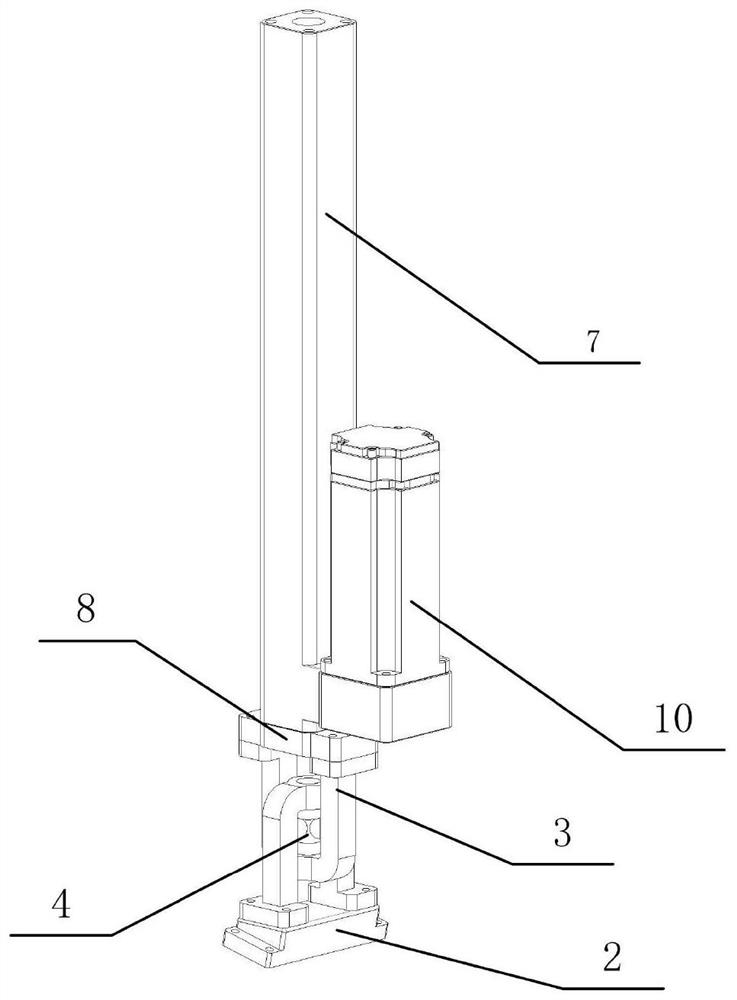

[0032] like figure 1 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com