Illuminating lamp for mine operation

A lighting and operation technology, which is applied in the field of mine operation equipment, can solve problems that affect the work of mine personnel, many attachments, and affect the quality of lighting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

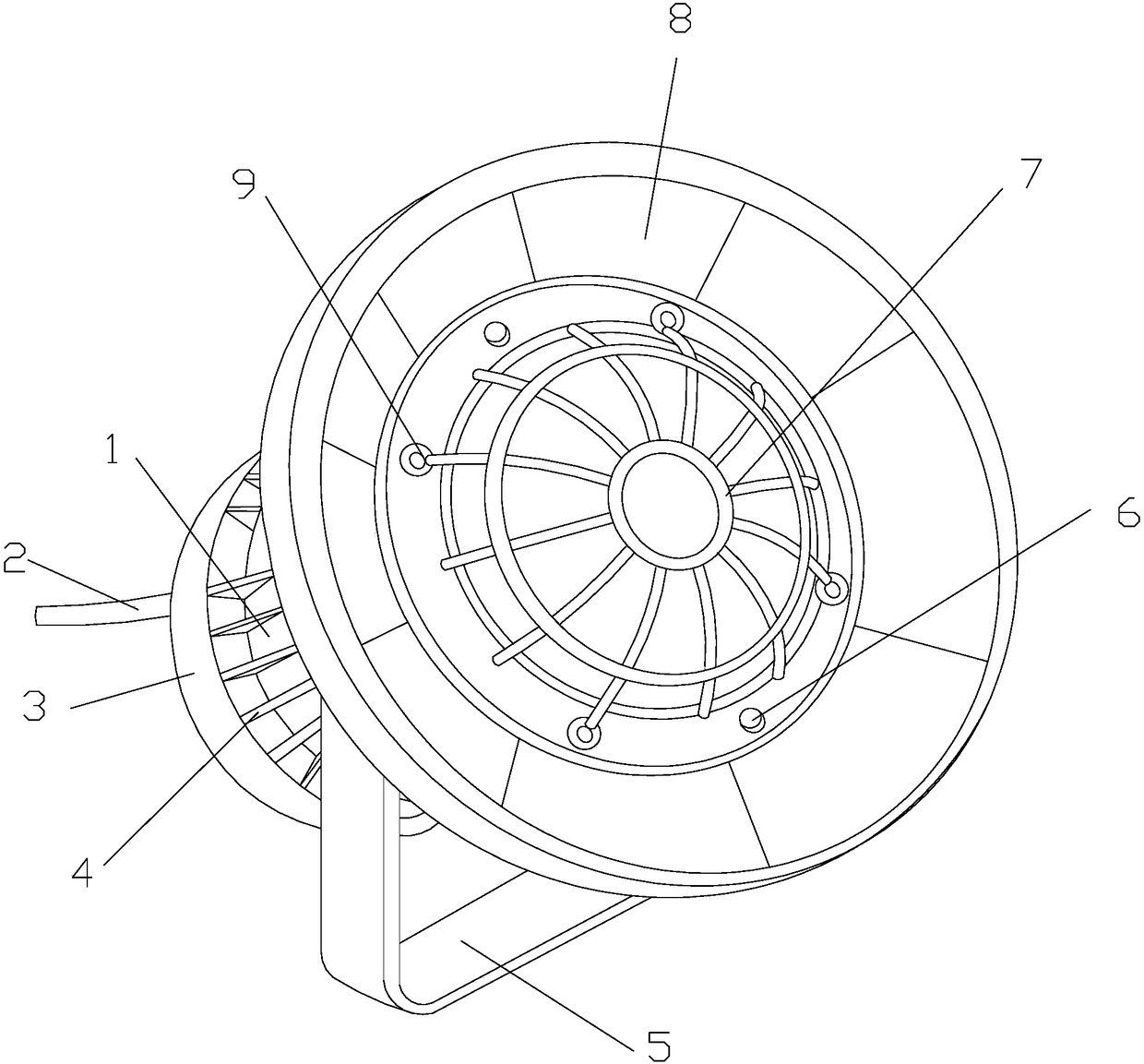

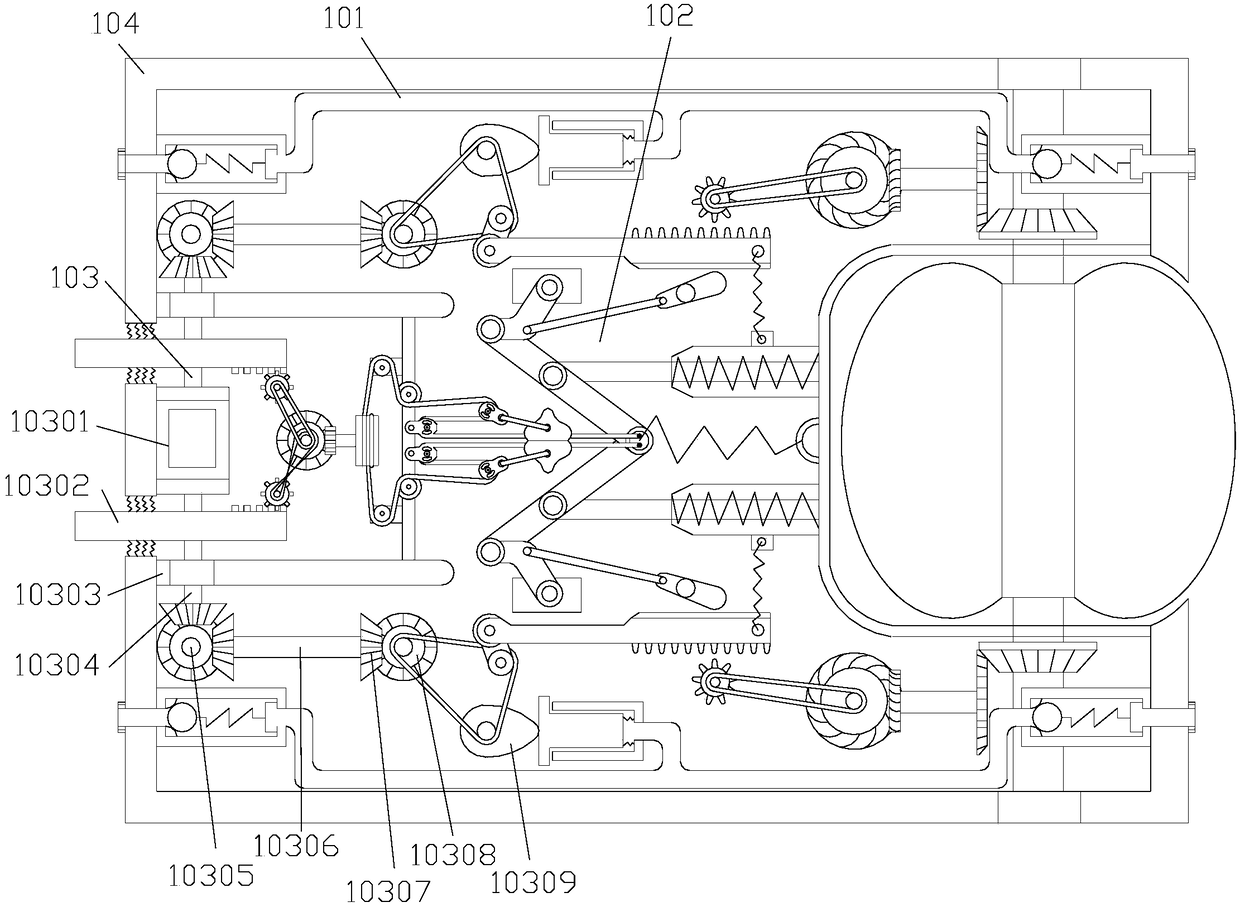

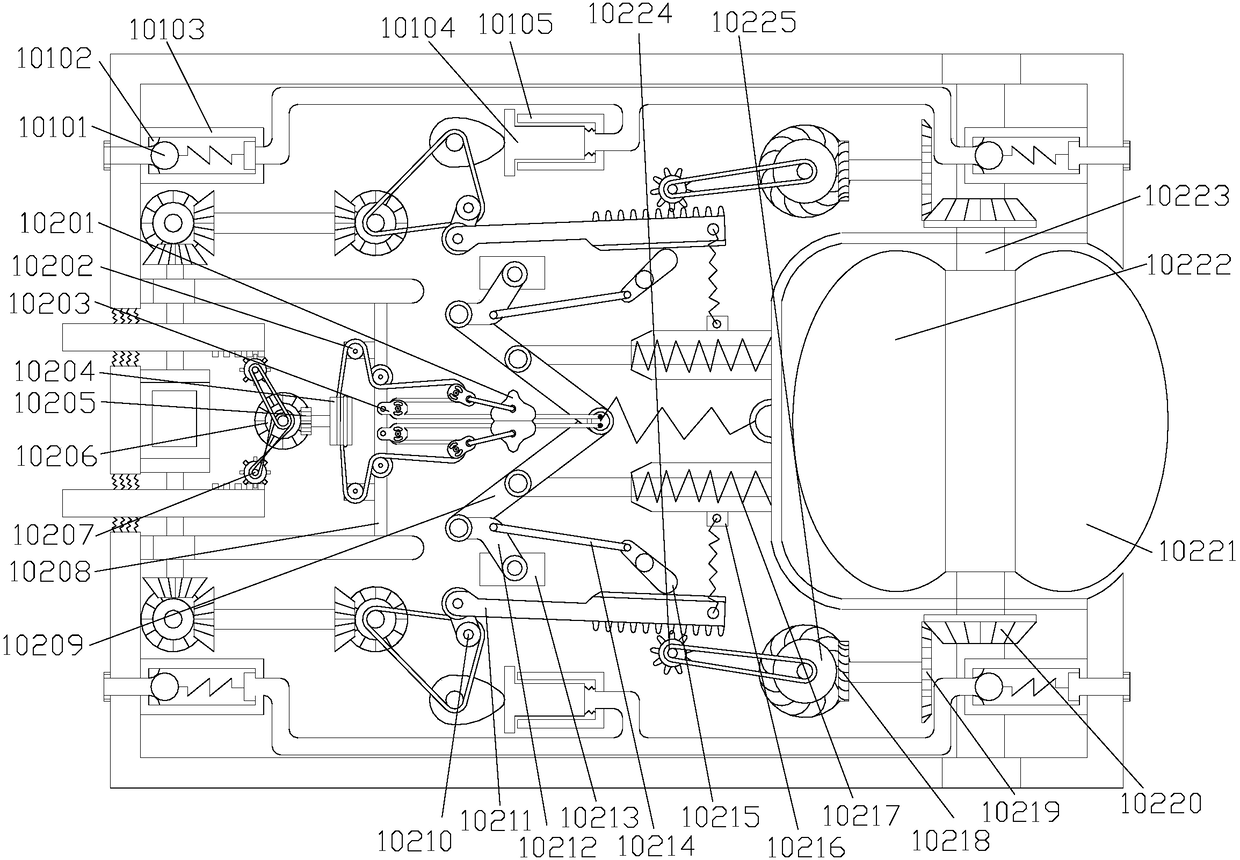

[0024] See Figure 1-Figure 4 , The present invention provides a technical solution for a lighting lamp for mine operations: its structure includes a ventilation and clear screen lighting device 1, a wire and a vent pipe bus 2, a rear cover 3, a heat sink 4, a support frame 5, a ventilation hole 6, a lamp cover 7 , Reflector 8, screw 9, the rear cover 3 of the venting and clearing lighting device 1 is provided with a rear cover 3, the wire and vent bus line 2 are provided on the back cover 3, and the heat sink 4 is distributed in the venting and clearing The outer ring of the screen lighting device 1 is connected to each other, the heat sink 4 and the tangent line of the outer ring of the ventilation and screen cleaning device 1 are perpendicular to each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com