A foam dressing raw material cutting device

A cutting device and raw material technology, applied in metal processing and other directions, can solve the problems of inconvenience in the cutting process of foam dressing raw materials, and achieve the effects of convenient and stable cutting process, strong practicability, and novel conception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

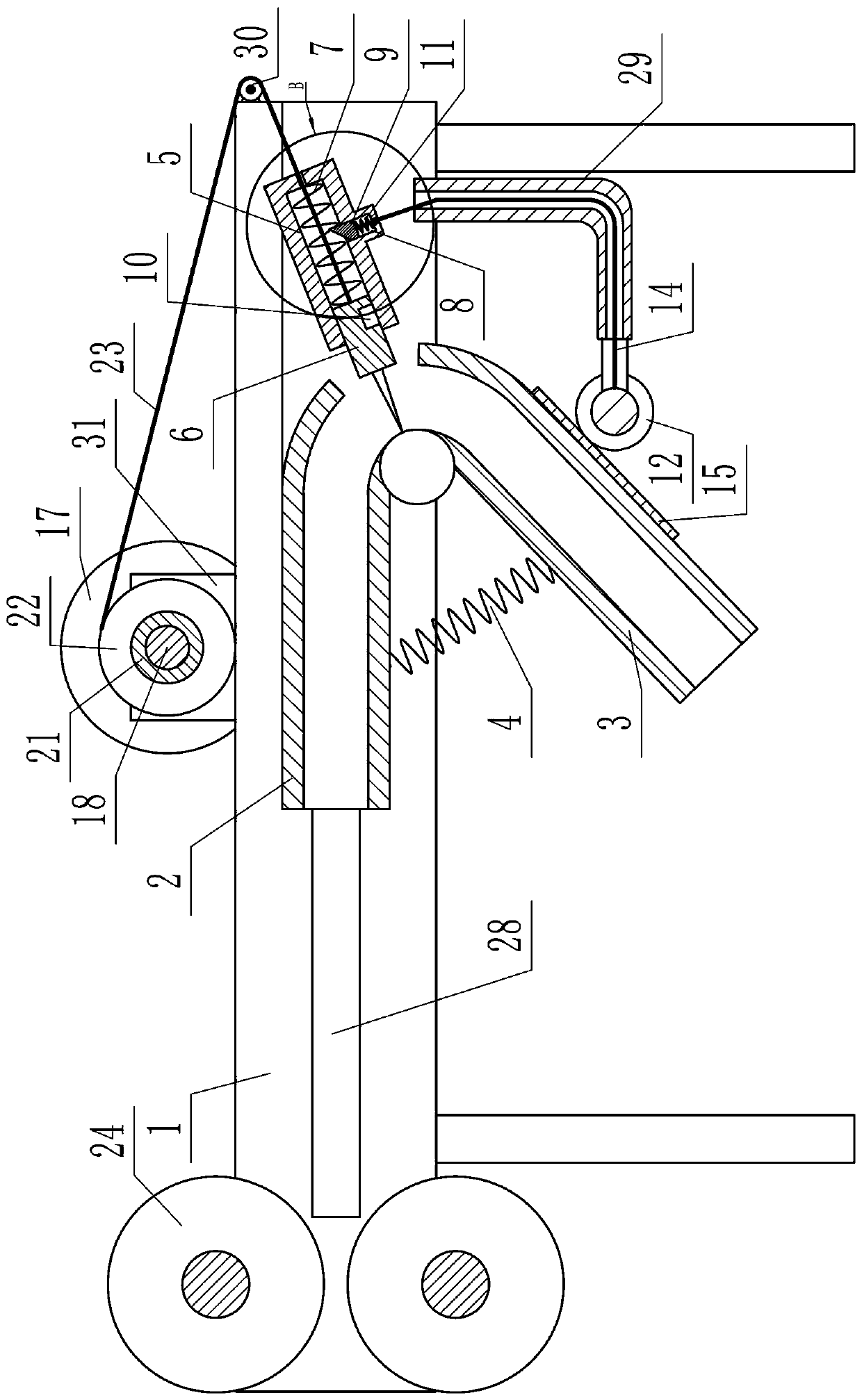

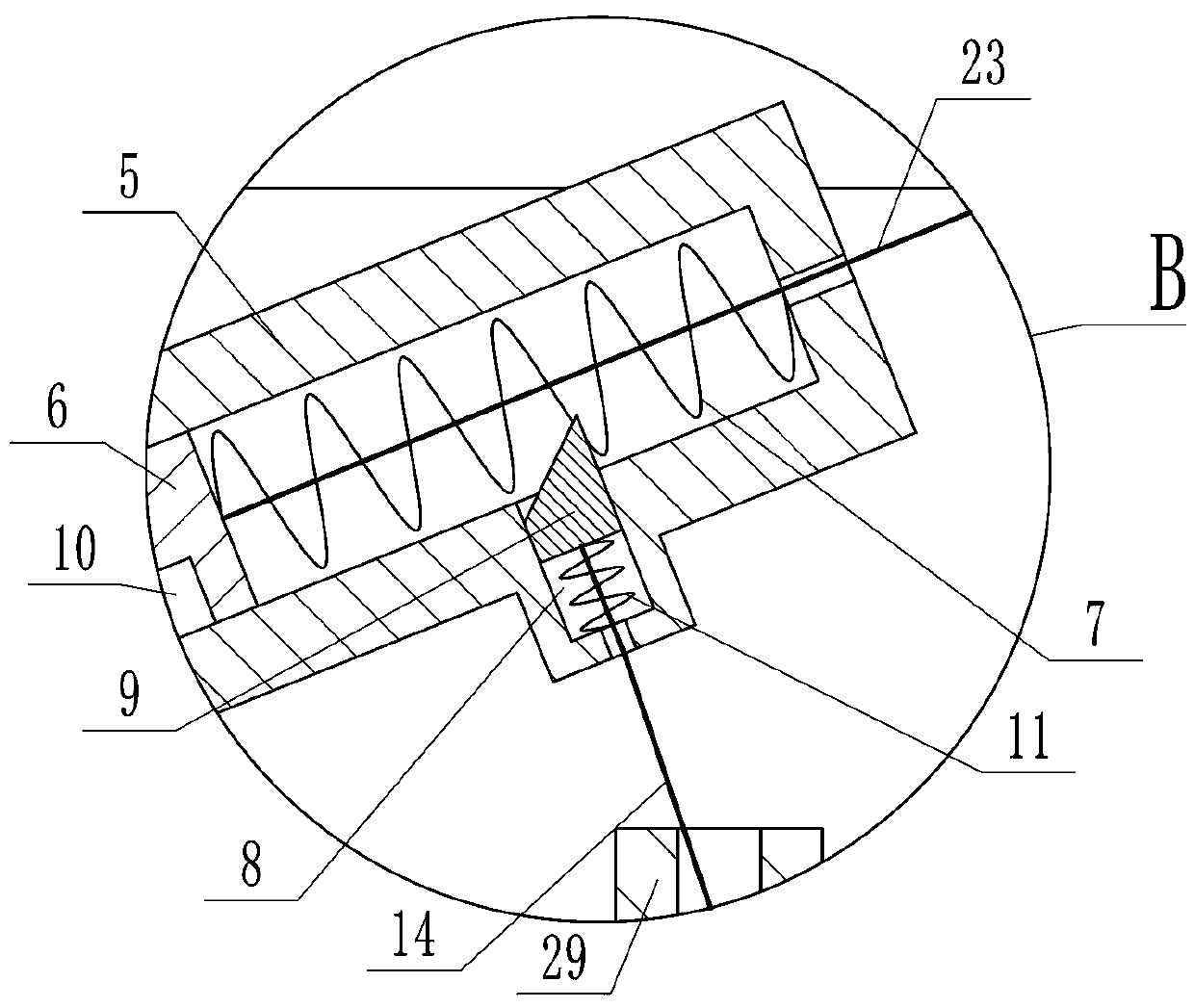

[0018] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0019] Depend on Figure 1 to Figure 7 It can be seen that the present invention includes a horizontally placed frame 1, and a transverse tube 2 movable left and right and having a rectangular cross section is arranged in the frame 1, and a vertical tube 3 is hinged to the right end of the horizontal tube 2, and the horizontal tube 2 and the vertical tube 3 form a Bend pipe, the bend of the bend pipe is smoothly transitioned, the vertical pipe 3 rotates around the hinge position to realize the closing and opening of the bend of the bend pipe, and the first compression spring 4 is connected between the horizontal pipe 2 and the vertical pipe 3;

[0020] The right side of the elbow is provided with a cylinder 5 radially placed along the arc of the bend of the elbow. A second compression spring 7 is connected to the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com