Dual-flow-pass fan guide vane adjusting mechanism

An adjustment mechanism and dual-channel technology, which can be used in axial flow pumps, mechanical equipment, machines/engines, etc., to solve the limitation of the guide vane adjustment angle range, not fully applicable to dual-channel fans, and unable to meet the large-angle guide vanes of dual-channel fans. The requirements of range adjustment and other issues can avoid interference and reduce airflow loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

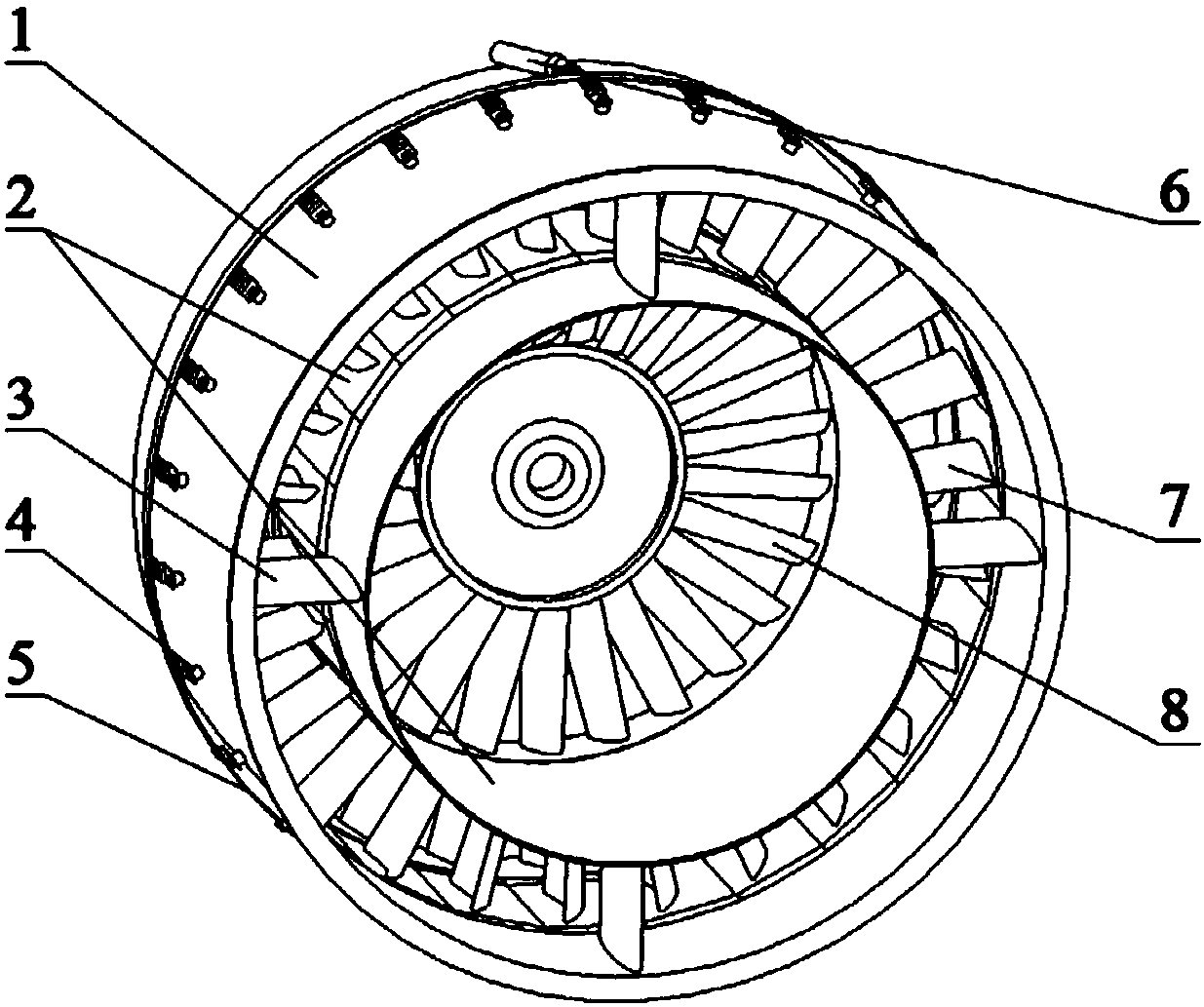

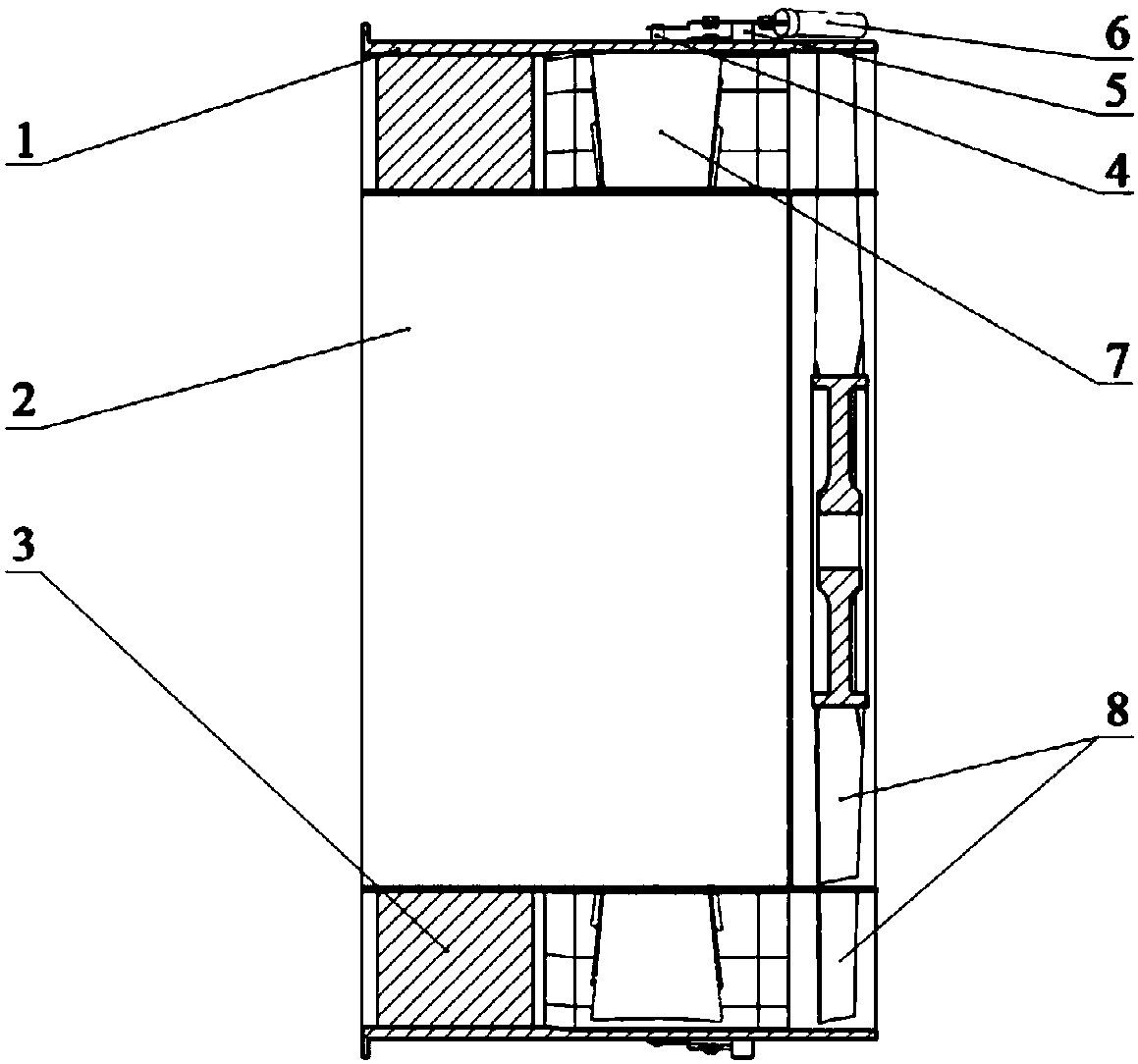

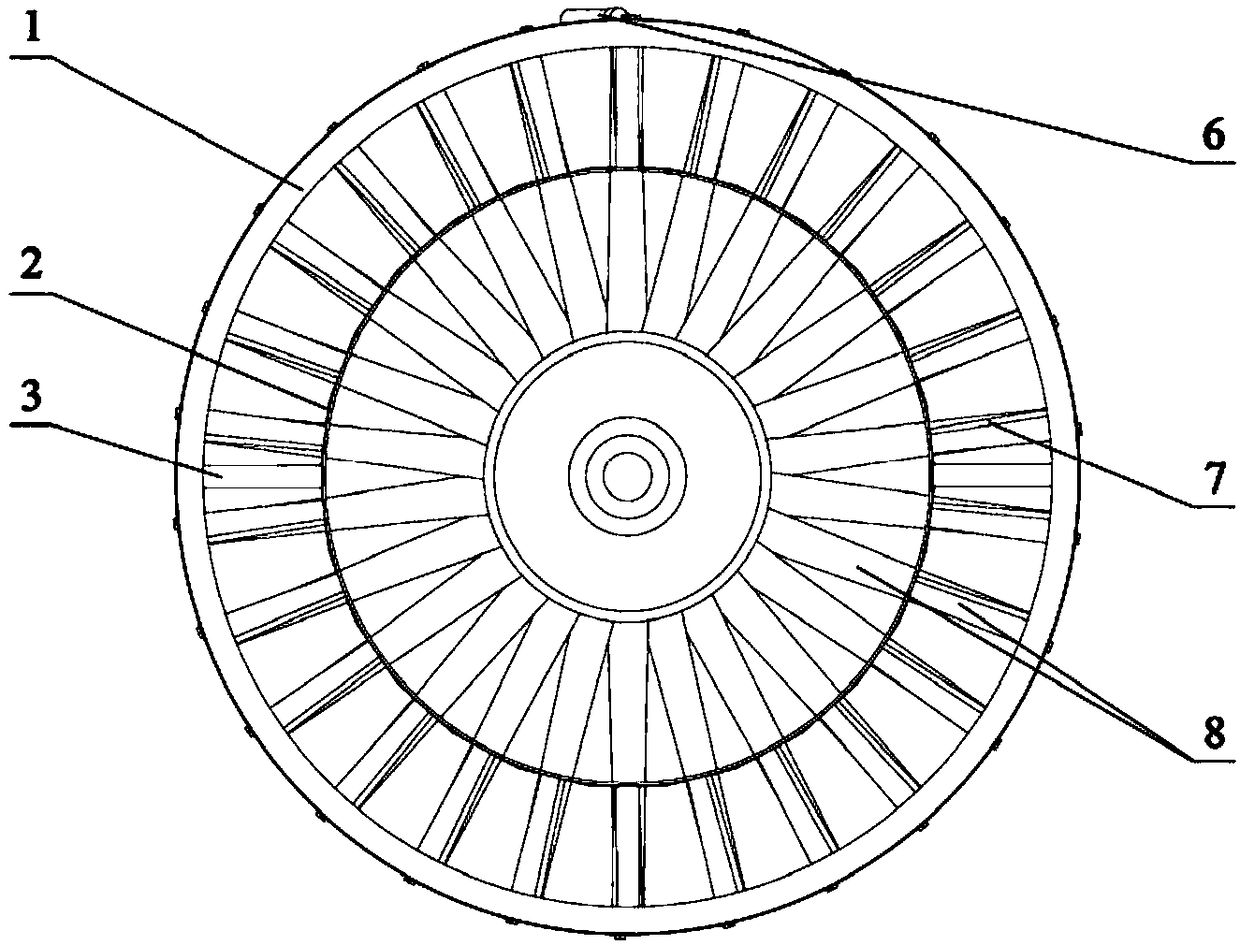

[0020] Such as Figures 1 to 8 As shown, the described dual-channel fan guide vane adjustment mechanism is characterized in that it includes an actuating cylinder 6 arranged on the outer casing 1 of the engine, the actuating ring 5 is connected with the actuating cylinder 6, and the actuating ring 5 passes through the The connecting rod mechanism 9 is connected with the rotating shaft 4 of the dual-channel fan guide vane, the rotating shaft 4 of the dual-channel fan guide vane is arranged on the outer case 1, and the dual-channel fan guide vane 7 is installed on the rotating shaft 4 of the dual-channel fan guide vane, and actuated The barrel 6 drives the moving ring 5 to drive the link mechanism 9 to rotate the dual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com