A Pressure regulation servo-valve with reduced leakage flow rate

A technology of pressure regulation and servo valve, which is applied in the direction of fluid pressure control, fluid pressure actuation device, servo motor assembly, etc., and can solve problems such as difficulty in starting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

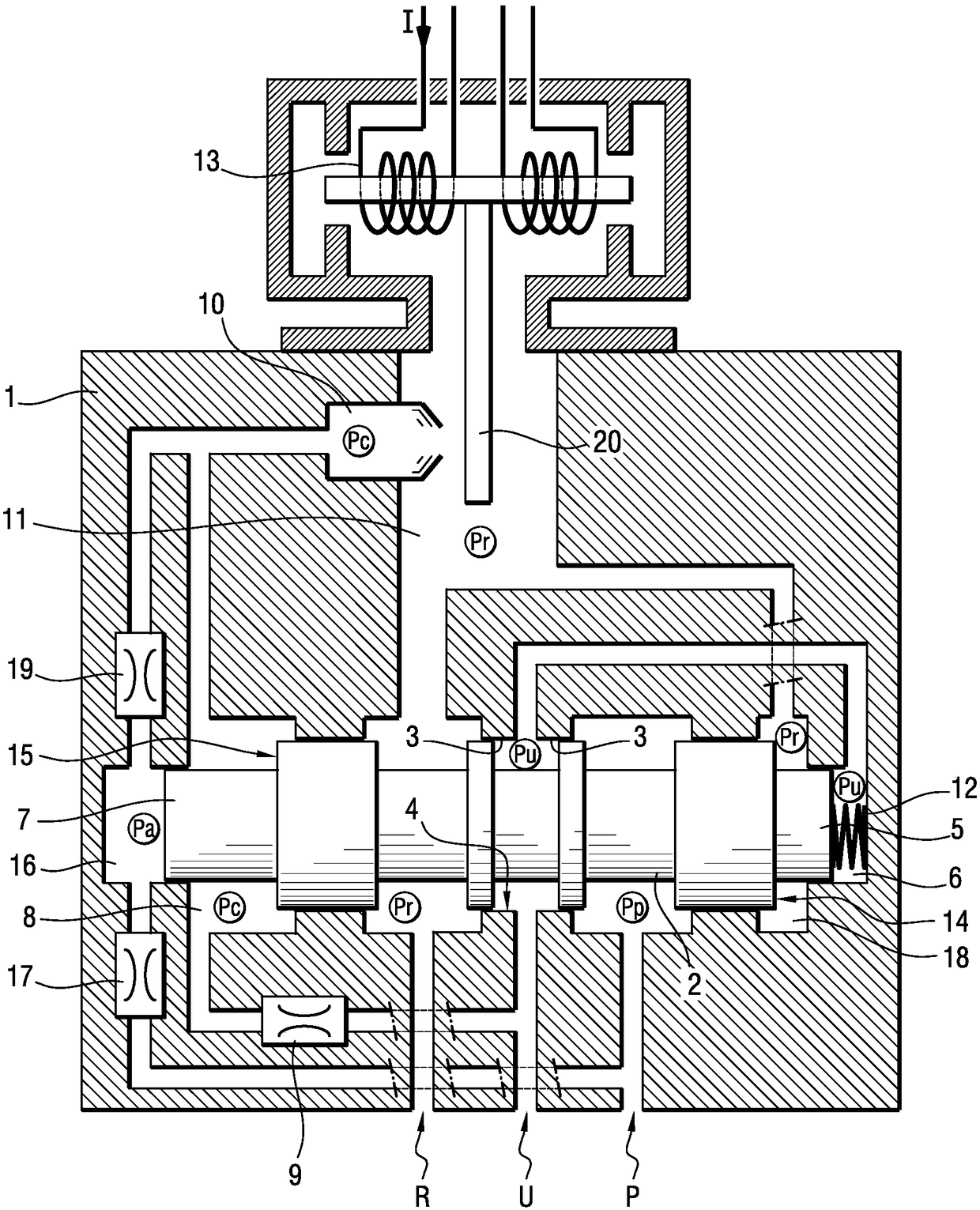

[0012] Referring to the drawings, the pressure regulator servo valve of the present invention comprises: a main body or cylinder 1 having a feed port P for connection to a source of hydraulic fluid under pressure; a return port R for connection to a to a tank (not shown); and with port U for connection to a piece of equipment, such as a hydraulic chamber (not shown) of an aircraft brake.

[0013] The spool 2 is slidably mounted in a calibrated orifice in the body 1 . The spool 2 has a land 3 cooperating with a central portion 4 of the calibrated orifice with slight clearance and extending firstly between the utilization port U and the return port R, and secondly between the utilization port U and the feed port P.

[0014] Due to the sliding gap between the table 3 and the central portion 4 of the calibration orifice, a channel providing communication between the utilization port U and both the return port R and the feed port P remains. In the position shown, the passage betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com