Al-mg-si aluminum alloy with excellent fatigue resistance and preparation method thereof

An aluminum alloy, fatigue resistance technology, applied in the field of Al-Mg-Si aluminum alloy and its preparation, can solve the problem of unfavorable safe application of Al-Mg-Si aluminum alloy, damage to the plasticity of Al-Mg-Si aluminum alloy, Unsatisfactory fatigue resistance of aluminum alloy and other problems, to avoid the decline of fatigue resistance, uniform distribution, and avoid the effect of natural aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] An Al-Mg-Si aluminum alloy with excellent fatigue resistance of the present invention is a 6061 aluminum alloy, and its specific composition is: by mass percentage, including 0.8% Mg, 0.4% Si, 0.3% Cu, 0.1% Mn, 0.1% Zn, 0.7% Fe, 0.1% Cr, and the balance is Al.

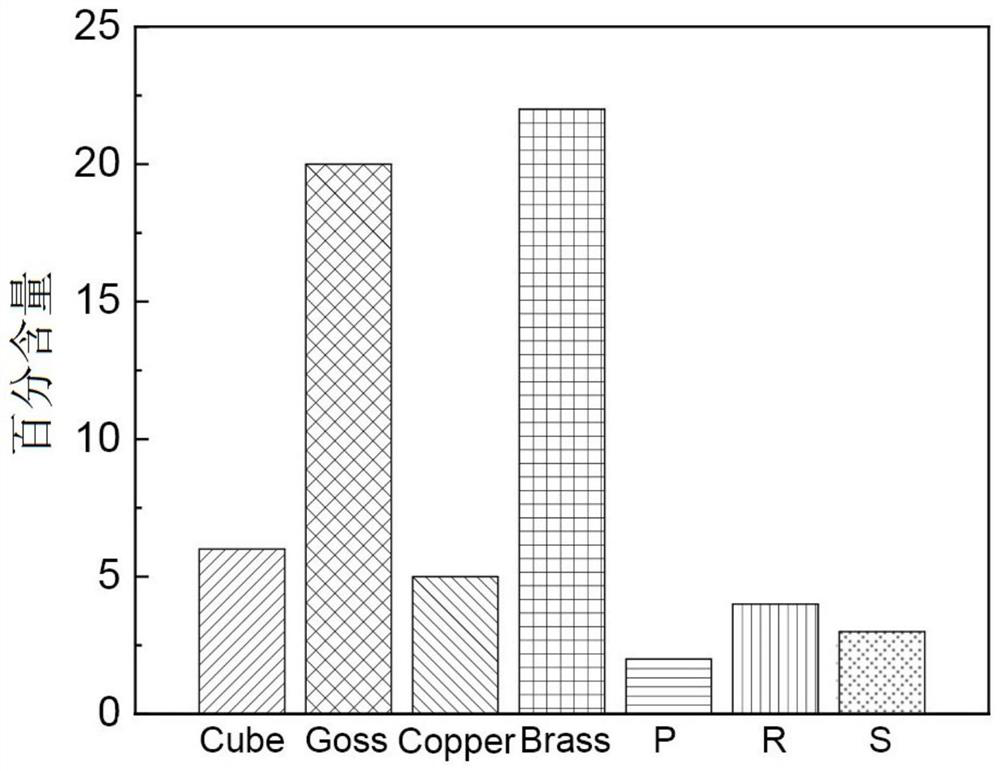

[0031] The Al-Mg-Si aluminum alloy of this example contains subgrains and α-Al phases inside the grains, and β-Mg at the grain boundaries and subgrain boundaries. 2 Si phase, and the subgrain boundary density is 3.5 times of the grain boundary density, the texture type is coexistence of Brass texture and Goss texture, and the percentages of Brass texture and Goss texture are 22% and 20% respectively.

[0032] A method for preparing an Al-Mg-Si aluminum alloy with excellent fatigue resistance in this embodiment, comprising:

[0033] After the homogenization treatment of the alloy, the forging deformation was carried out at 560°C with a true strain of 0.5, and then the creep aging was carried out at 250°C with a ...

Embodiment 2

[0036] An Al-Mg-Si aluminum alloy with excellent fatigue resistance of the present invention has the same chemical composition as that of Example 1.

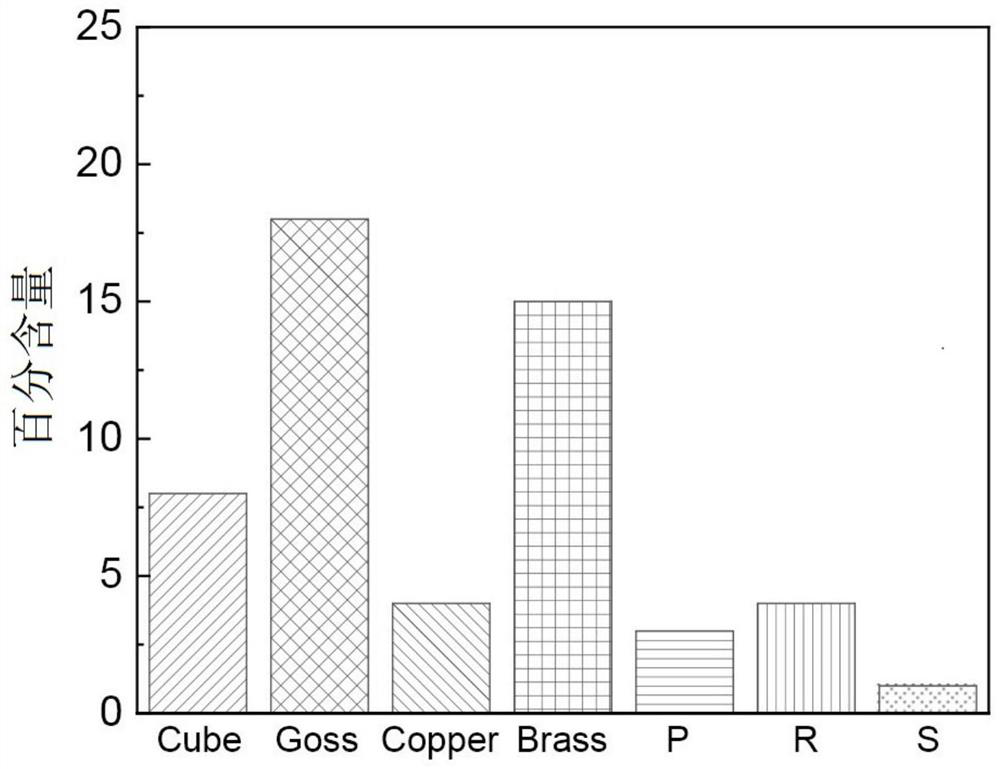

[0037] The Al-Mg-Si aluminum alloy of this example contains subgrains and α-Al phases inside the grains, and β-Mg at the grain boundaries and subgrain boundaries. 2 Si phase, and the subgrain boundary density is 3.2 times of the grain boundary density, the texture type is coexistence of Brass texture and Goss texture, and the percentages of Brass texture and Goss texture are 15% and 18%, respectively.

[0038] A method for preparing an Al-Mg-Si aluminum alloy with excellent fatigue resistance in this embodiment differs from the method in Example 1 only in that the true strain of thermal deformation is 0.3.

[0039] The obtained Al-Mg-Si aluminum alloy is marked as sample No. 2, which contains subgrains and α-Al phases inside the grains, and β-Mg at the grain boundaries and subgrain boundaries. 2 Si phase, the texture type is th...

Embodiment 3

[0058] An Al-Mg-Si aluminum alloy with excellent fatigue resistance of the present invention is a 6101 aluminum alloy, and its specific composition is: by mass percentage, including: 0.8% Mg, 0.6% Si, 0.1% Cu, 0.1% Zn , 0.2% Fe, 0.05% B, and the balance is Al.

[0059] A method for preparing an Al-Mg-Si aluminum alloy with excellent fatigue resistance in this embodiment, comprising:

[0060] After the homogenization treatment of the alloy, extrusion deformation at 500°C to a true strain of 0.5, then creep aging at 210°C to a true strain of 0.2, and regression treatment at 180°C for 30 minutes, and finally at 120°C Carry out 12h of artificial aging, that is.

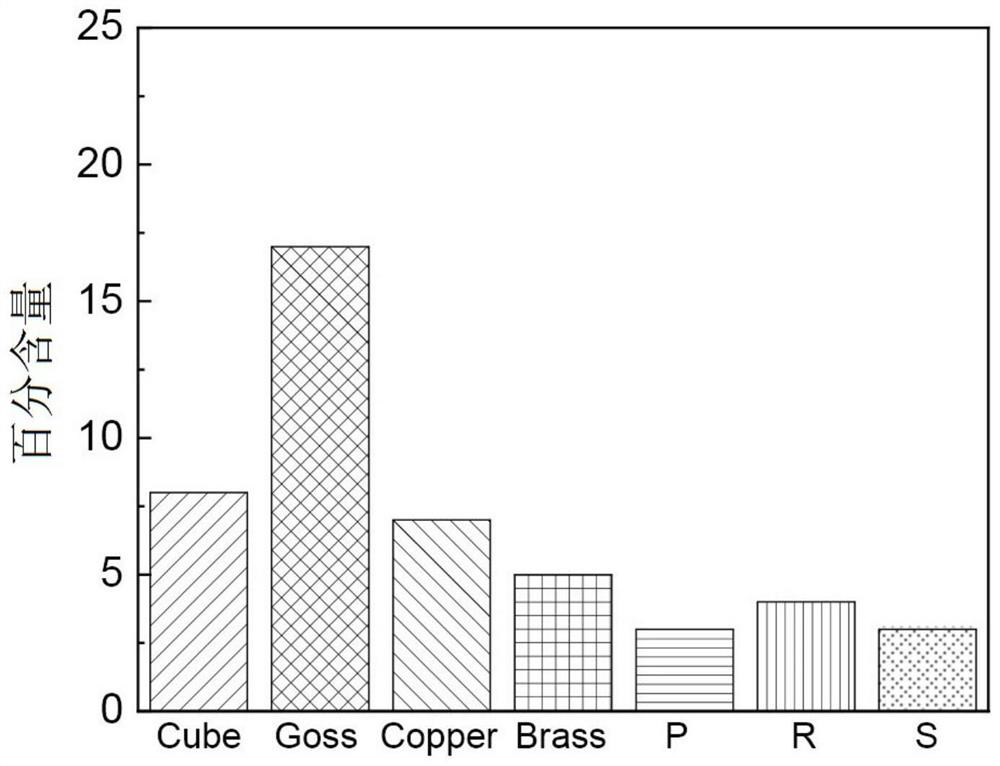

[0061] The obtained Al-Mg-Si aluminum alloy is marked as sample No. 6, which contains subgrains and α-Al phases inside the grains, and β-Mg at the grain boundaries and subgrain boundaries. 2 Si phase, and the sub-grain boundary density is 4.2 times of the grain boundary density, the texture type is the coexistence of Br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com