Face gear planetary transmission type string fine-adjustment mechanism

A technology of planetary transmission and fine-tuning mechanism, applied in the direction of gear transmission, transmission, transmission parts, etc., can solve the problems of tuning accuracy and quality influence, poor long-term use effect, inability to fine-tune the strings, etc., to adapt to the work. Narrow space, reduced occupied space, good working space narrow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

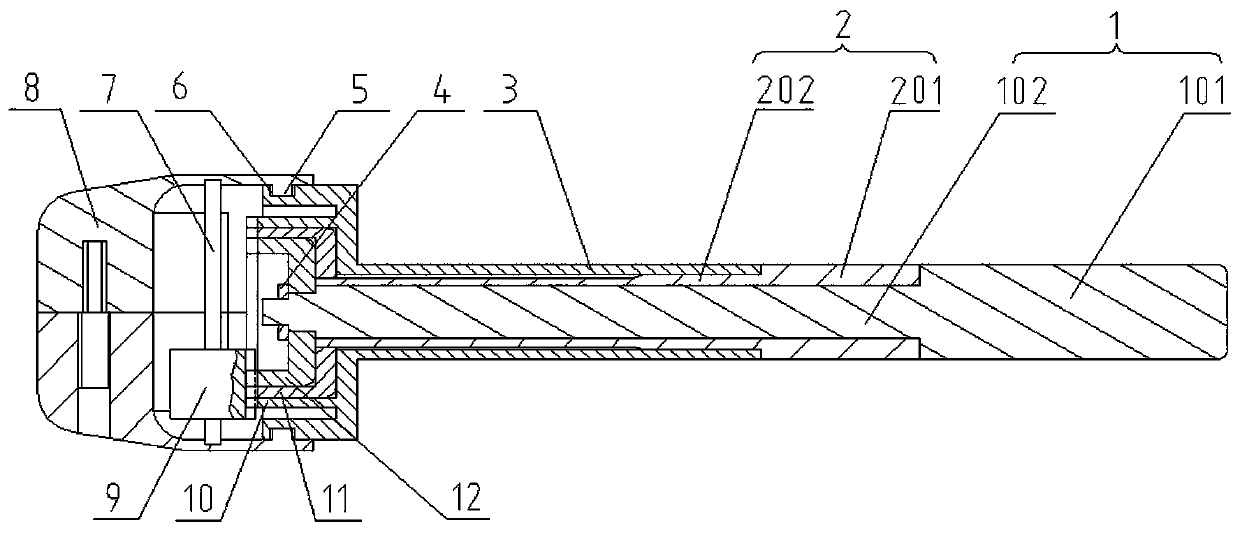

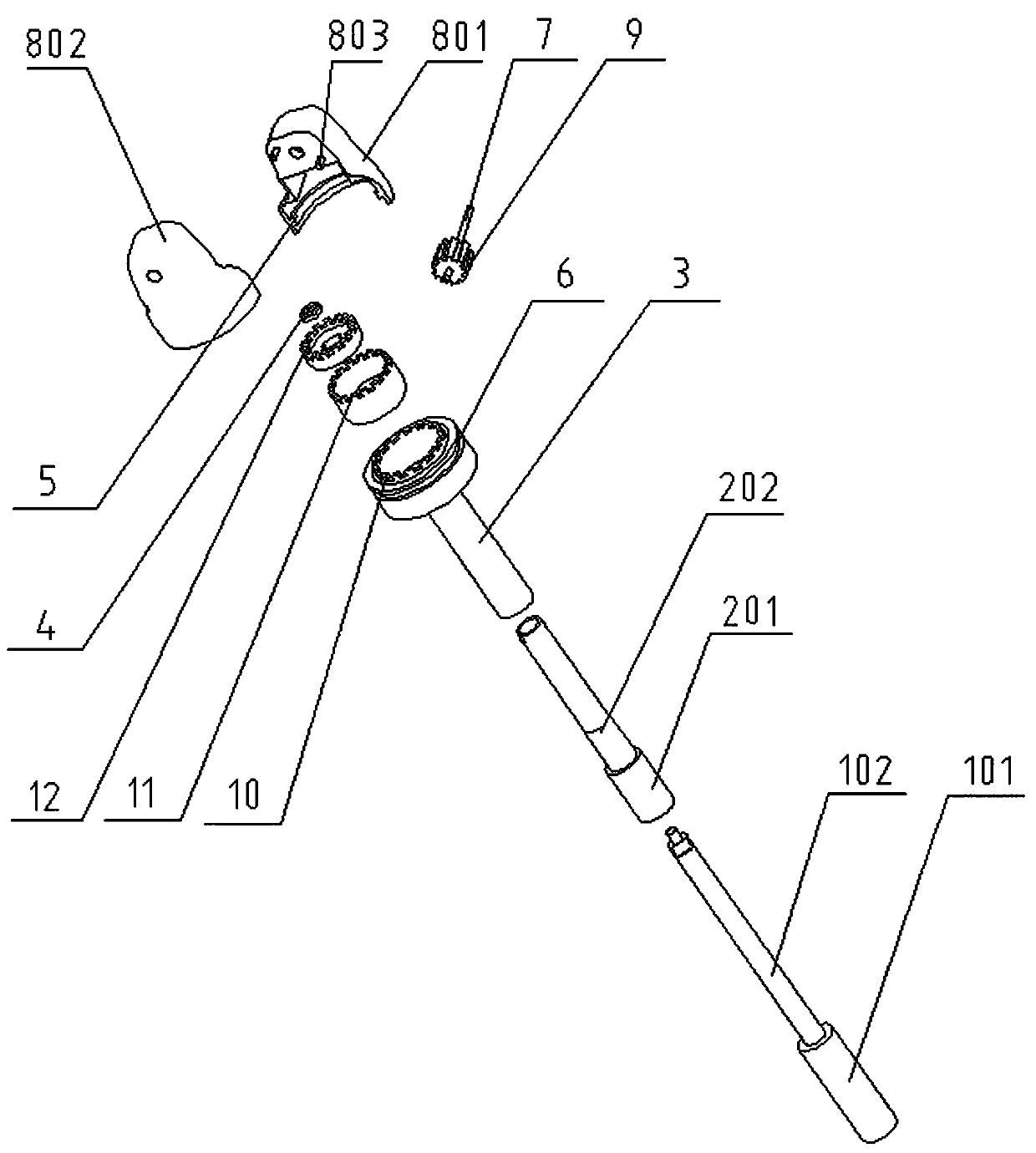

[0021] Such as figure 1 and figure 2 As shown, a string fine-tuning mechanism through face gear planetary transmission of the present invention includes a reel shaft 2, a positioning shaft 3 rotatably sleeved outside the reel shaft 2, and a rotatably sleeved inside the reel shaft 2. The positioning mandrel 1. The positioning mandrel 1 and the positioning shaft 3 are respectively used for fixing with two opposite perforations provided on the headstock, the reel shaft 2 can rotate relative to the positioning mandrel 1 and the positioning shaft 3, and can be fixed by being fixed with the strings. Adjust the tightness of the strings with the rotation of the spool shaft 2.

[0022] Both the mandrel shaft 2 and the positioning mandrel 1 are stepped, and both include a large-diameter section and a small-diameter section connected coaxially. The small-diameter section of the drum shaft 2 is the drum inner shaft 202, and is installed in the positioning shaft 3, and the large-diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com