String fine-tuning mechanism based on planetary gear transmission with small tooth difference

A planetary and gear transmission technology with less tooth difference, applied in the direction of gear transmission, transmission, transmission parts, etc., can solve the problems of tuning accuracy and quality influence, poor long-term use effect, poor tuning accuracy, etc. The effect of small vibration, reducing the space occupied, and increasing the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

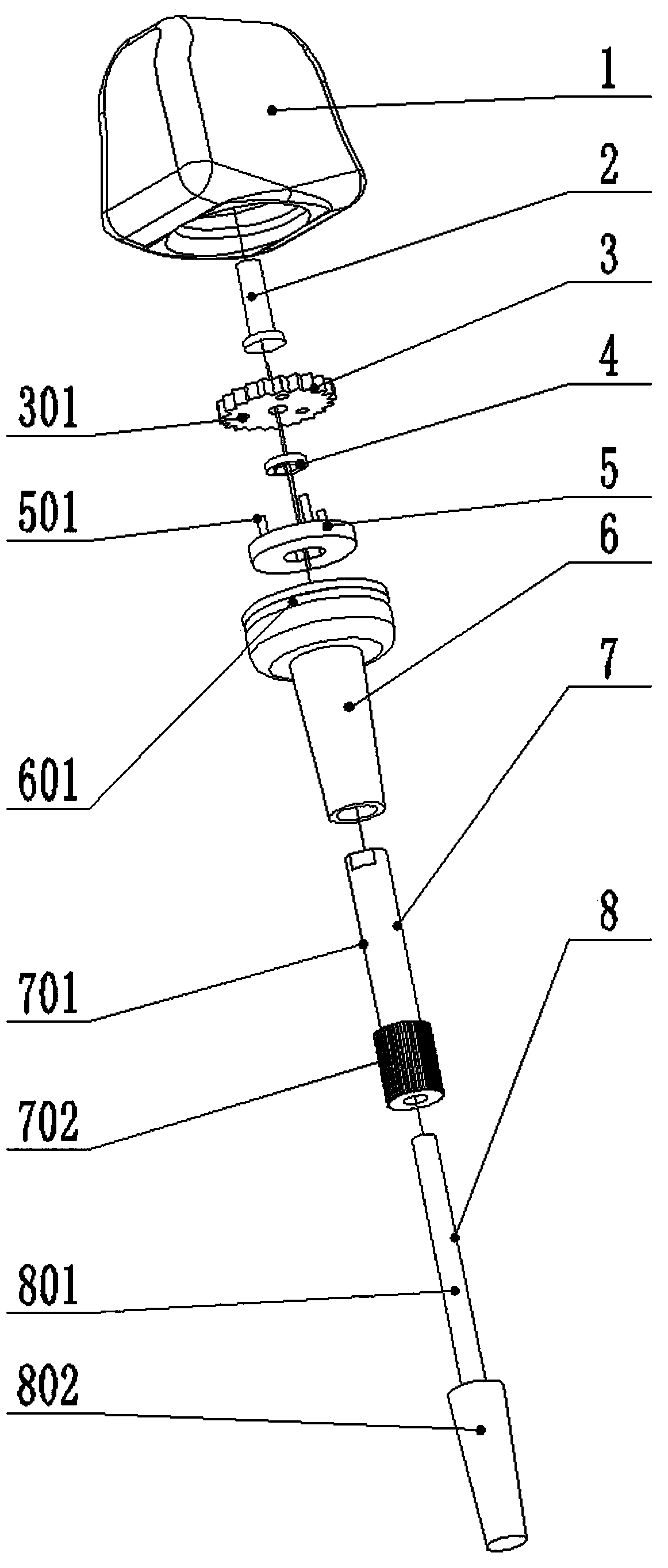

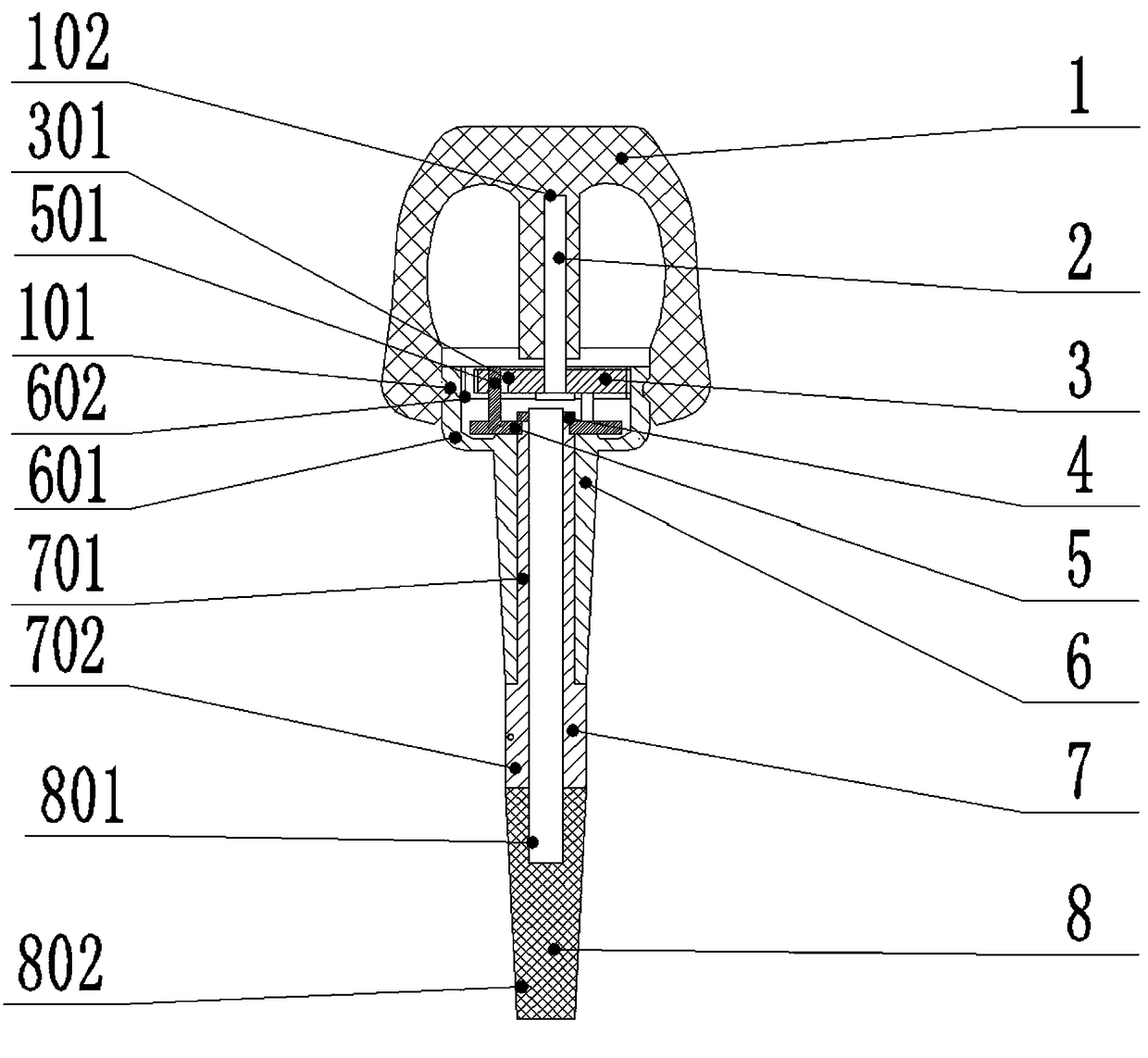

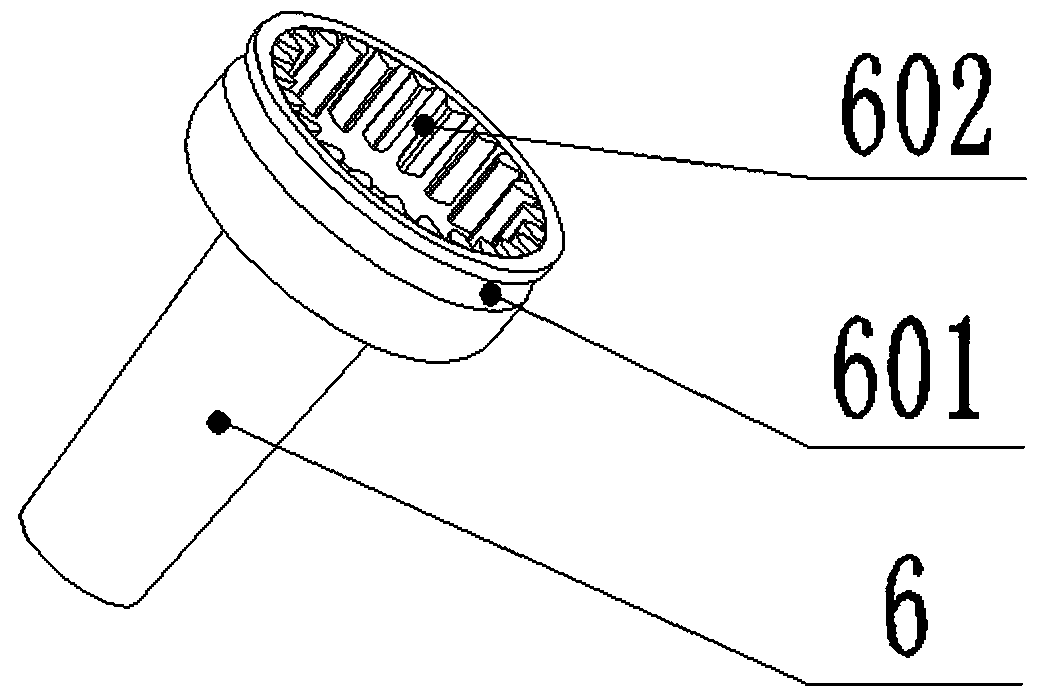

[0025] like figure 1 and figure 2 As shown, a string fine-tuning mechanism driven by a planetary gear 3 with a small tooth difference of the present invention includes a positioning sleeve shaft 6, a spool shaft 7 coaxially rotated in the positioning sleeve shaft 6, and a coaxially rotating drum shaft 7 arranged in the positioning sleeve shaft 6. The positioning mandrel 8 in the mandrel shaft 7 and the adjustment device. The rotation of the adjusting device can drive the reel shaft 7 and its small rotation angle to rotate, thereby realizing fine-tuning of the tightness of the strings fixed on the reel outer shaft 702 .

[0026] Both the spool shaft 7 and the positioning mandrel 8 are stepped shafts. The spool shaft 7 includes coaxially distributed small-diameter sections and large-diameter sections. The small-diameter sections form the spool inner shaft 701 and are installed in the positioning sleeve shaft 6 with clearance fit. The spool outer shaft 702 formed by the large-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com