Automatic rubber sleeve mounting device

An installation device and rubber sleeve technology, applied in the field of pipe fittings processing, can solve the problems of inability to make containers and difficult to eliminate processing efficiency, and achieve the effects of being beneficial to material loading, high work efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The technical solutions of the present invention will be further described below in conjunction with the drawings and specific implementations.

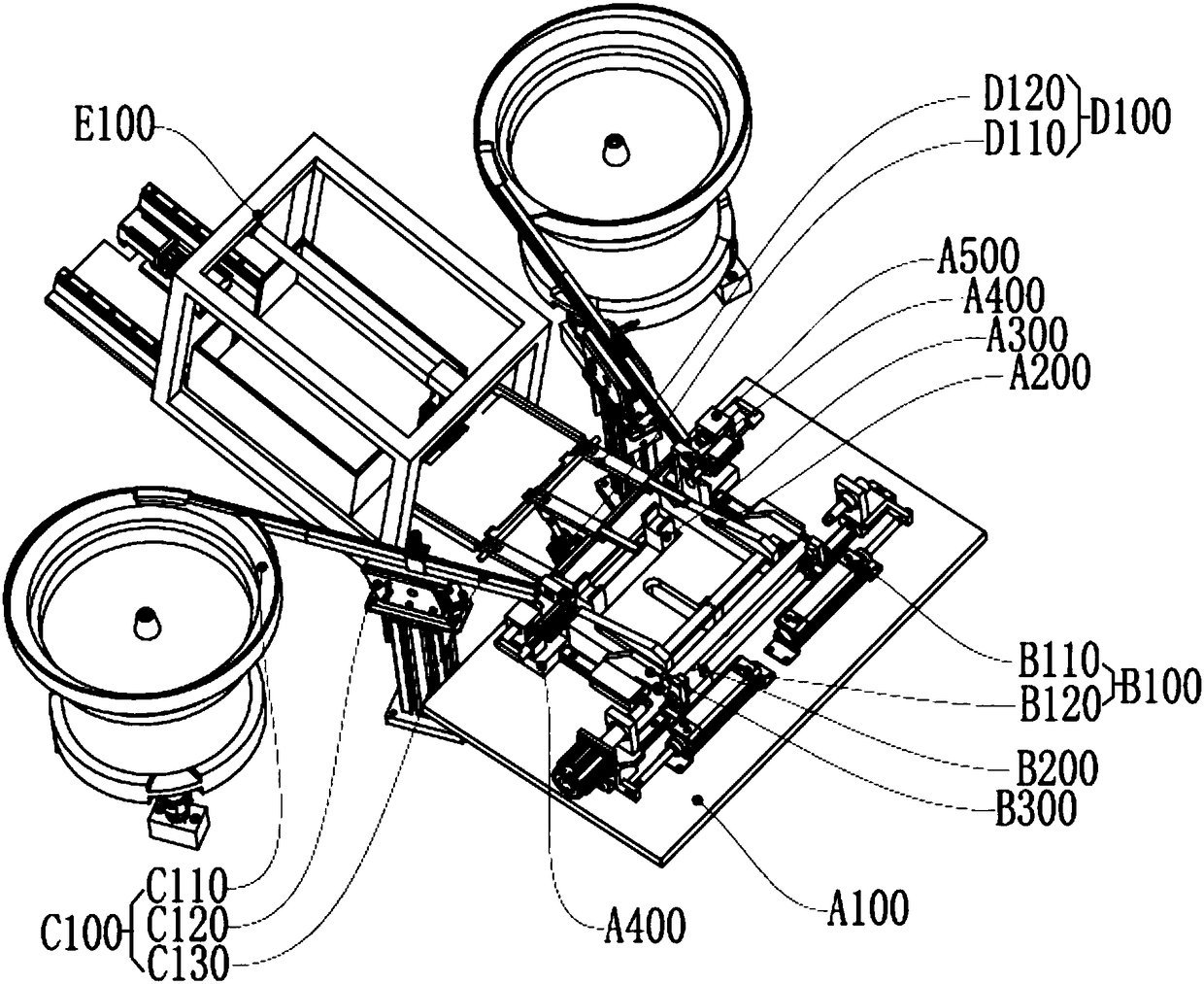

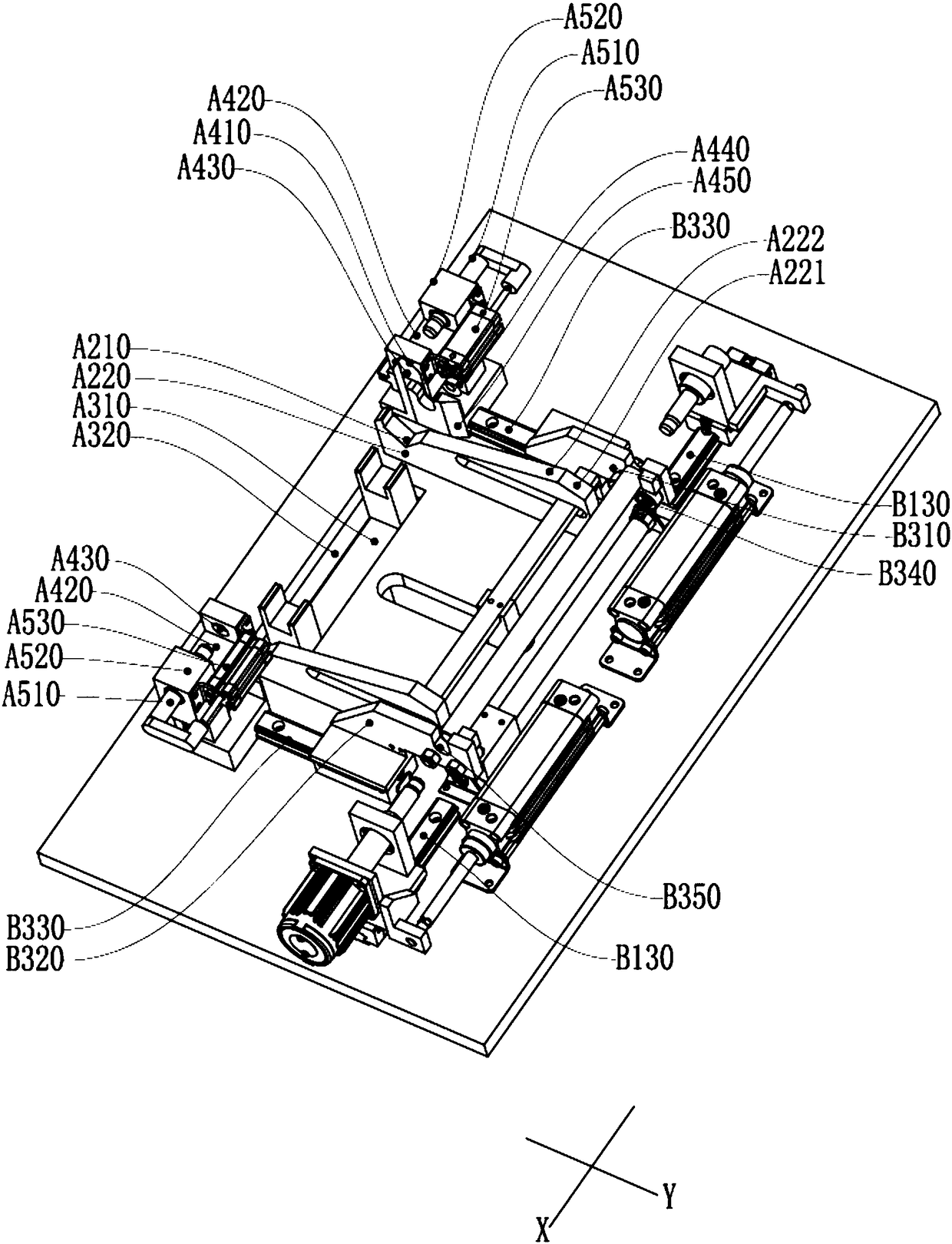

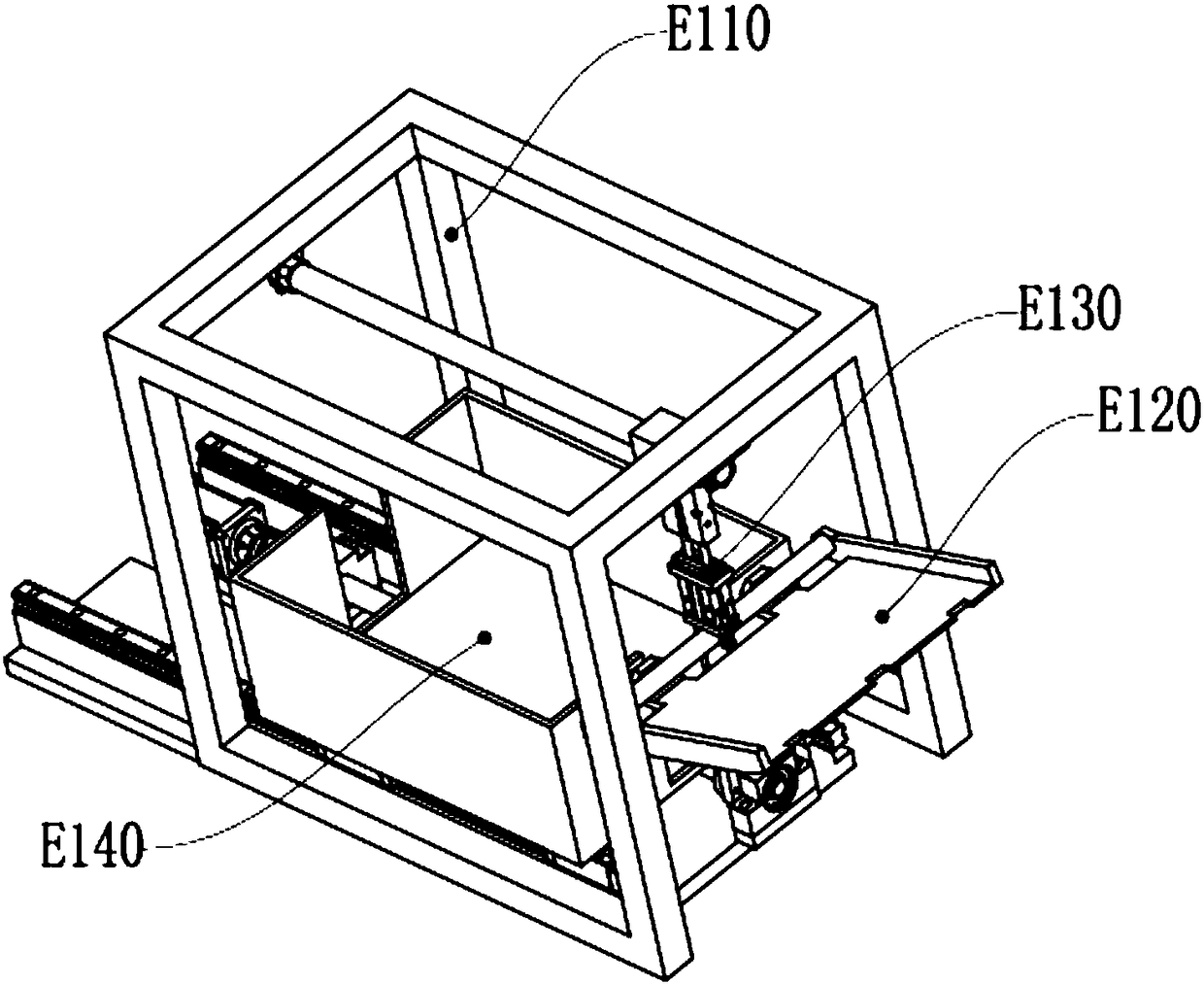

[0051] Such as Figure 1-3 As shown, an automatic rubber sleeve installation device includes a base plate A100, and also includes a pre-positioning device A200, a workpiece lifting device A300, a positioning die A400, and a rubber sleeve installation device A500;

[0052] The pre-positioning device A200 is fixedly installed on the base plate A100, the pre-positioning device A200 is provided with a pre-positioning slot A210 with an upward opening, and the positioning mold A400 is installed on the base plate A100. Positioning dies A400 are installed oppositely on both sides of the position slot A210;

[0053] The upper part of the positioning die A400 is provided with a workpiece positioning groove A410 with a downward opening, the workpiece lifting device A300 is installed below the pre-positioning device A200, and the telescopic rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com