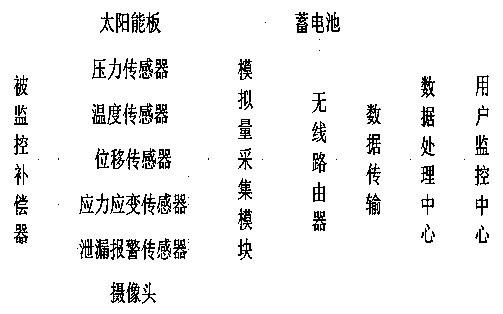

Monitoring and early warning device for metal bellow compensator and monitoring method of monitoring and early warning device

A corrugated compensator and early warning device technology, applied in heating methods, central heating sensors, household heating and other directions, can solve problems such as reduced service life, stress corrosion, corrugated pipe damage, etc., to solve sudden damage, energy saving, installation convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

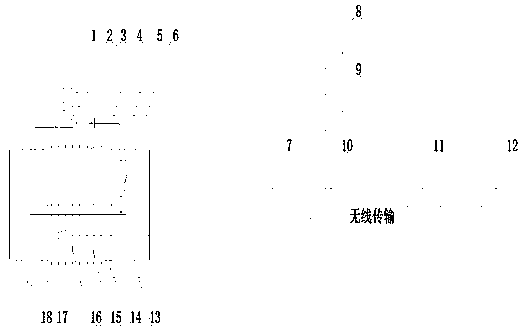

[0039] Such as Figure 2~9 As shown, the bellows 15 is made of thin-walled multi-layer stainless steel plate metal, and the number of thin-walled layers is 2 layers.

[0040] Thin-walled multi-layer corrugated pipe 15 (1 to 2 layers from outside to inside), at the straight end of one side of the corrugated pipe 15, the first layer of corrugated pipe 24 has a through hole with a diameter of 12mm, and the outer diameter is 10mm, the inner diameter is 4mm, and the length is 50mm The tube base 122 is placed in the through hole, the inner surface is even, and the inner and outer surfaces are welded. Two parallel wires 19 are placed in the tube base 22 with a distance of 2mm, and the insertion depth is 40mm. It is potted with epoxy resin potting glue 23. The potting depth is 35 mm, and the lead wire drawn from the socket 1 22 is connected to the leakage alarm sensor 14 .

[0041] A monitoring method for a metal corrugated compensator monitoring and early warning device, comprising ...

Embodiment 2

[0046] Such as Figure 2~9 As shown, the bellows 15 is made of thin-walled multi-layer stainless steel plate metal, and the number of thin-walled layers is 3 layers.

[0047] Thin-walled multi-layer corrugated pipe 15 (1 to 3 layers from outside to inside), at the straight end of one side of the corrugated pipe 15, the first layer of corrugated pipe 24 has a through hole with a diameter of 12mm, and the outer diameter is 10mm, the inner diameter is 4mm, and the length is 50mm The pipe seat 22 is put into the through hole, the inner surface is flat, and the inner and outer surfaces are welded. At the pipe seat 22 with an arc length of 50 mm, the first layer of corrugated pipe 24 and the second layer of corrugated pipe 25 are opened with through holes. The hole size Same as above, put in the pipe seat 2 21, the inner surface is even, the inner and outer surfaces are welded, and the interlayer is penetrated, and two parallel wires 19 are placed in the pipe seat 1 22 and the pipe ...

Embodiment 3

[0053] Such as Figure 2~9 As shown, the corrugated pipe 15 is made of thin-walled multi-layer stainless steel plate metal, and the number of thin-walled layers is 5 layers.

[0054] Thin-walled multi-layer corrugated pipe 15 (1 to 3 layers from outside to inside), at the straight end of one side of the corrugated pipe 15, the first layer of corrugated pipe 24 has a through hole with a diameter of 12mm, and the outer diameter is 10mm, the inner diameter is 4mm, and the length is 50mm The first layer of corrugated pipe 22 is put into the through hole, the inner surface is even, and the layers are welded through. Dimensions are the same as above, put into the tube base 21, the inner surface is even, the inner and outer surfaces are welded, and the interlayer is welded through. At the tube base 21 arc length 50mm, open the first to third layer of corrugated pipes 24-26 through holes , the hole size is the same as above, put it into the pipe seat 3 20, the inner surface is even, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com