Energy-saving and environment-friendly efficient oil refining machine capable of dehydrating hogwash oil in vacuum and removing impurities and odor

A technology of energy saving, environmental protection and vacuum dehydration. It is applied in the direction of oil/fat refining and fat production. It can solve problems such as pollution of the environment, and achieve the effects of reducing pollution, low processing and production costs, and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

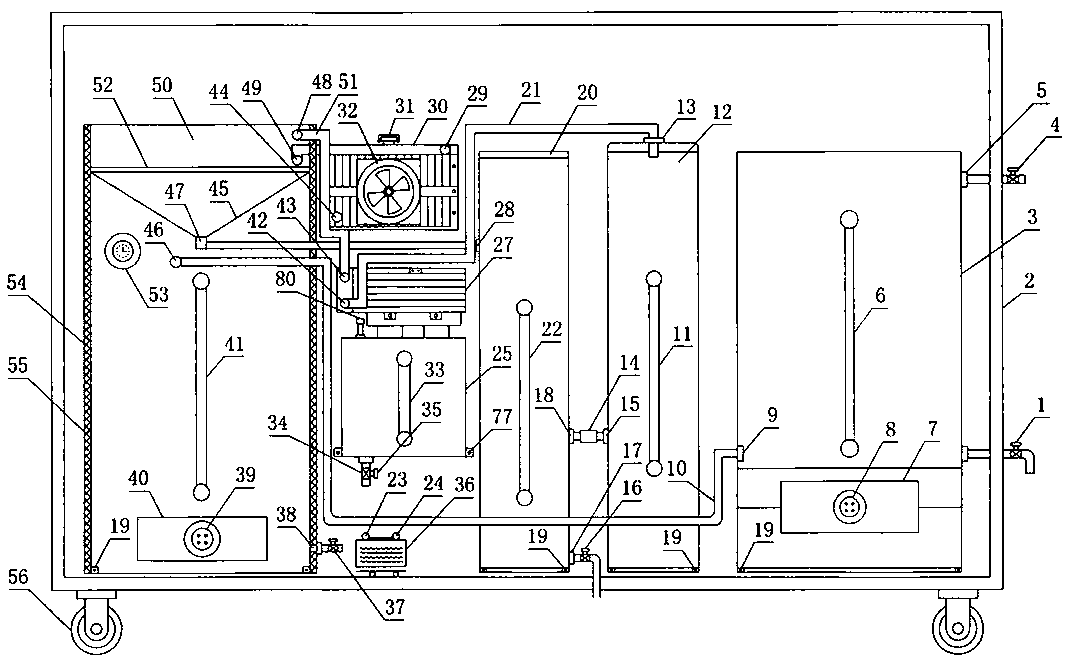

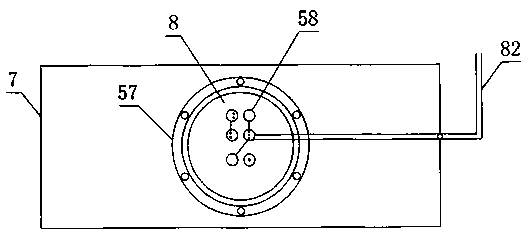

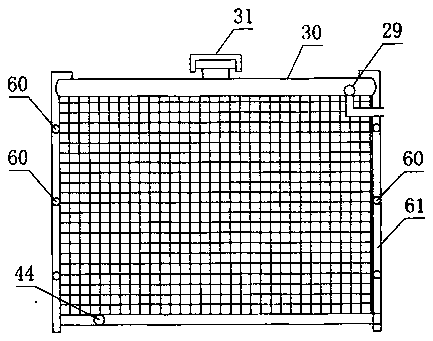

[0018] Figure 1-6 The refining machine body 2 shown in the figure is provided with a swill oil reserve oil refinery tank 3, the left end of the reserve oil refinery tank is provided with a vacuum cooling gas storage tank 12, and the left end of the vacuum cooling gas storage tank is provided with a vacuum cooling tank 20, The upper left end of the vacuum cooling tank is provided with a radiator 30, the front side of the radiator is provided with an axial flow fan 32, the lower end of the radiator is provided with a vacuum pump 27, the inner end of the vacuum pump is provided with a vacuum pump motor 70, and the lower end of the vacuum pump motor is provided with a circulation Water tank 25, the downside of circulating water tank is provided with gear oil pump 36, and the left side of circulating water tank is provided with vacuum refining tank 54. The oil reserve refining tank, the vacuum cooling gas storage tank, the vacuum cooling tank and the vacuum refining tank are insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com