Kitchen stirring and grinding device

A grinding device and kitchen technology, applied in grain processing and other directions, can solve problems such as single functional structure, and achieve the effects of improving conveying efficiency, high mixing degree and uniform size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following describes the embodiments in further detail to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

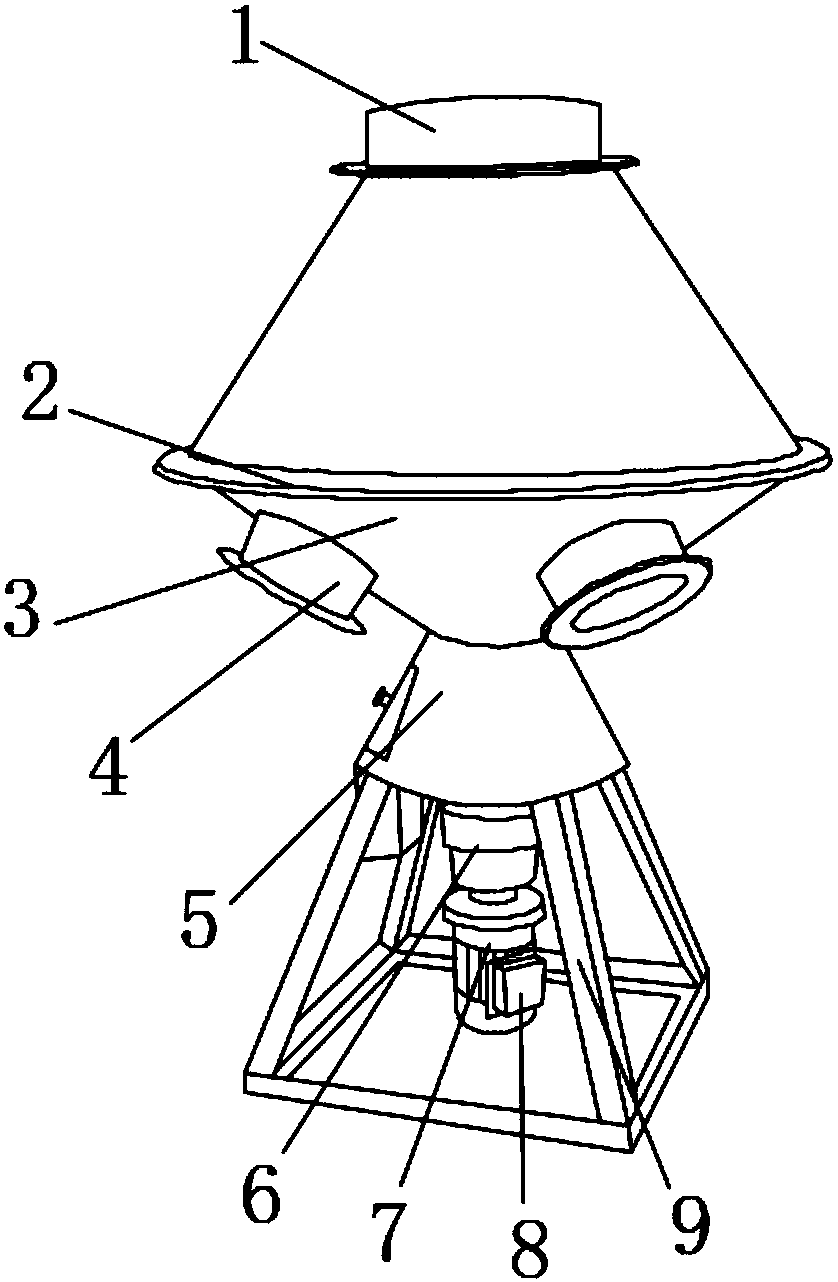

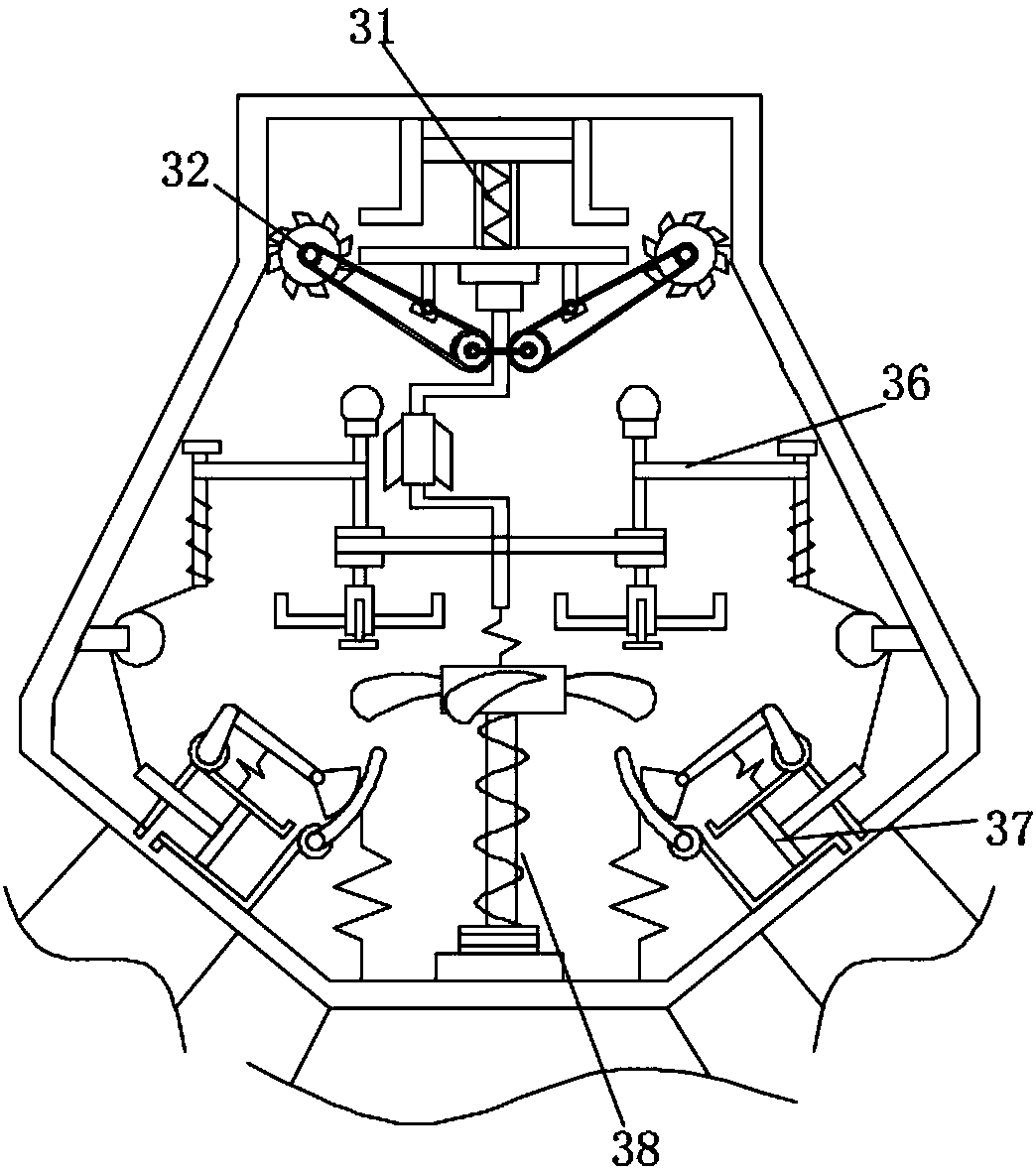

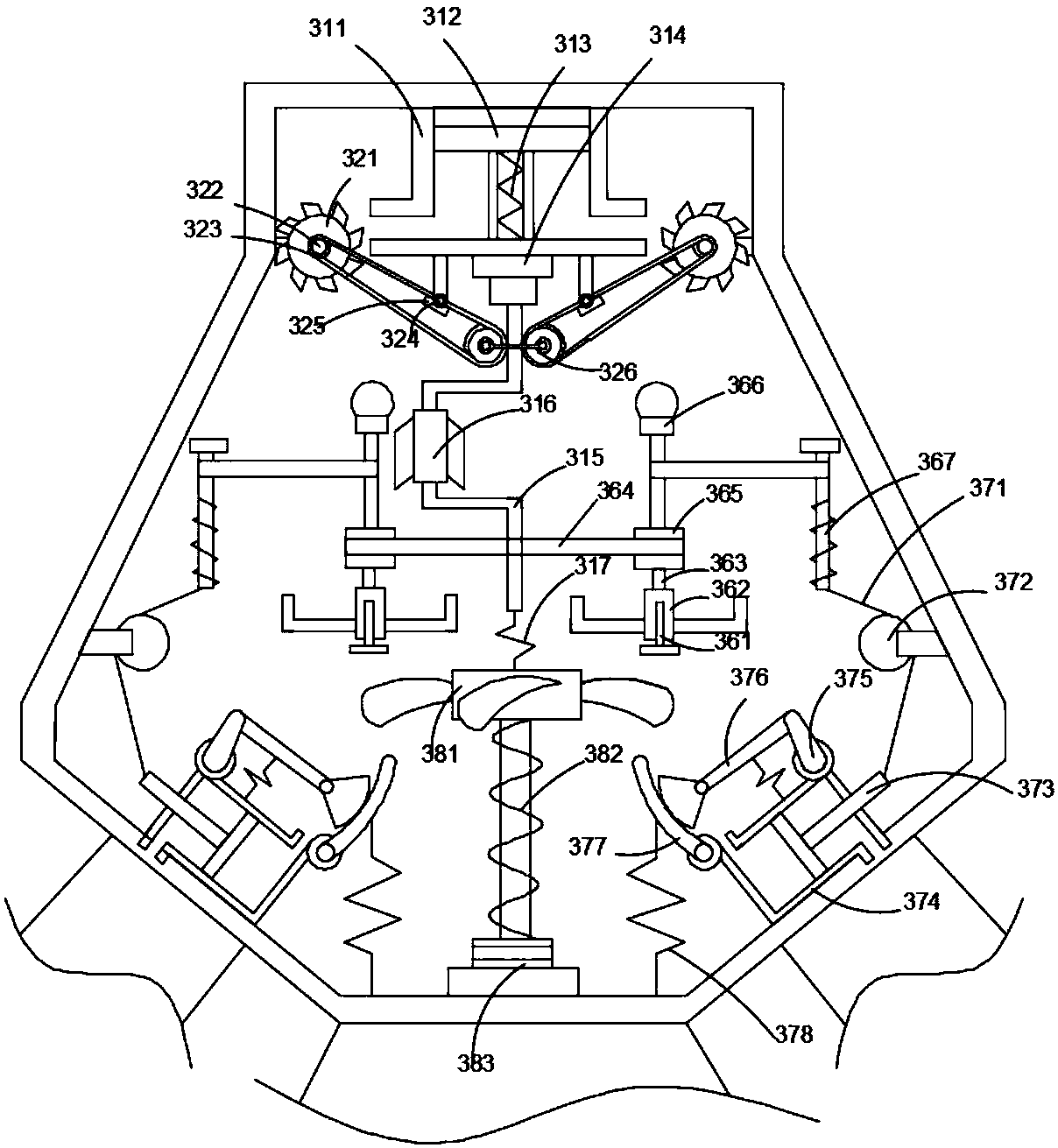

[0021] Such as Figure 1-3 , a kitchen mixing and grinding device, its structure includes: feed port 1, flange ring 2, stirring grinder 3, discharge chute 4, round platform base 5, shaft drum 6, spindle motor 7, power distribution block 8 and support 9, the stirring grinder 3 is made of drum device 31, transmission mechanism 31, shaft rod mechanism 36, piston device 37 and stirring mechanism 38; wherein, transmission mechanism 32, shaft rod mechanism 36, piston device 37 all have two One, and symmetrically arranged on the left and right sides of the drum device 31, the drum device 31 is installed on the top of the agitating grinder 3 and communicates with the feed port 1, the transmission mechanism 32 is installed at the lower end of the drum devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com