Combined tie-rod axles for vehicles

A tie-rod and axle technology, which is applied in the field of combined tie-rod axles, can solve the problems of too far from the center of the wheel and adverse effects on axle rotation performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

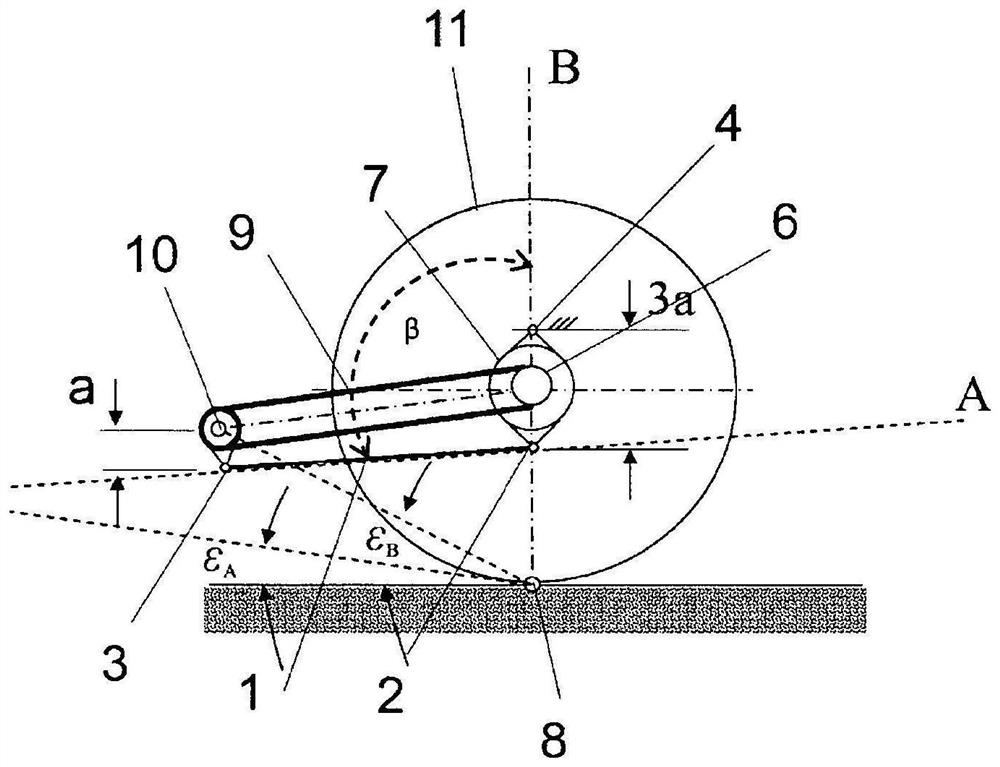

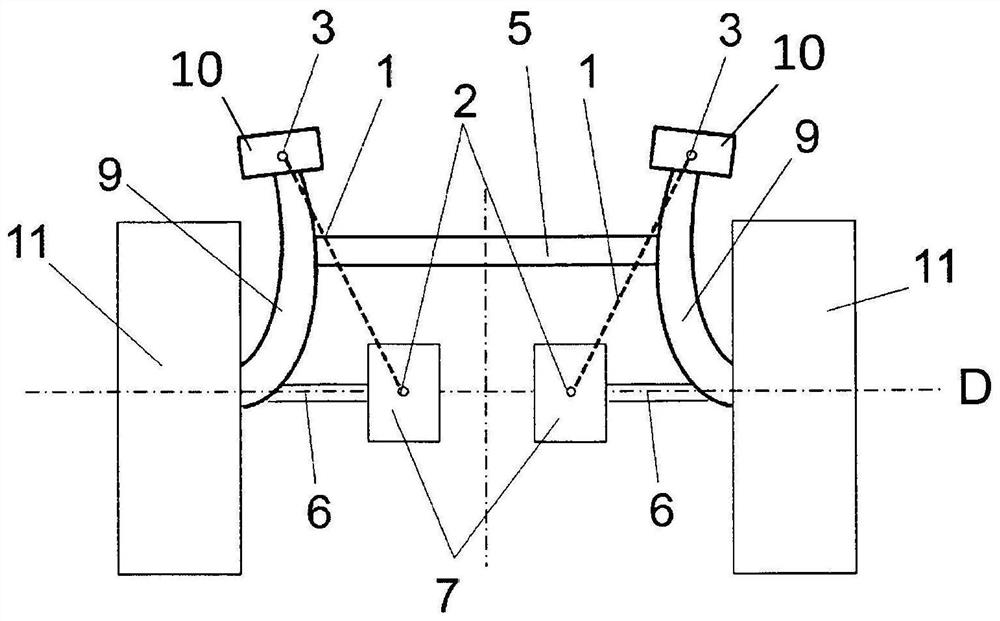

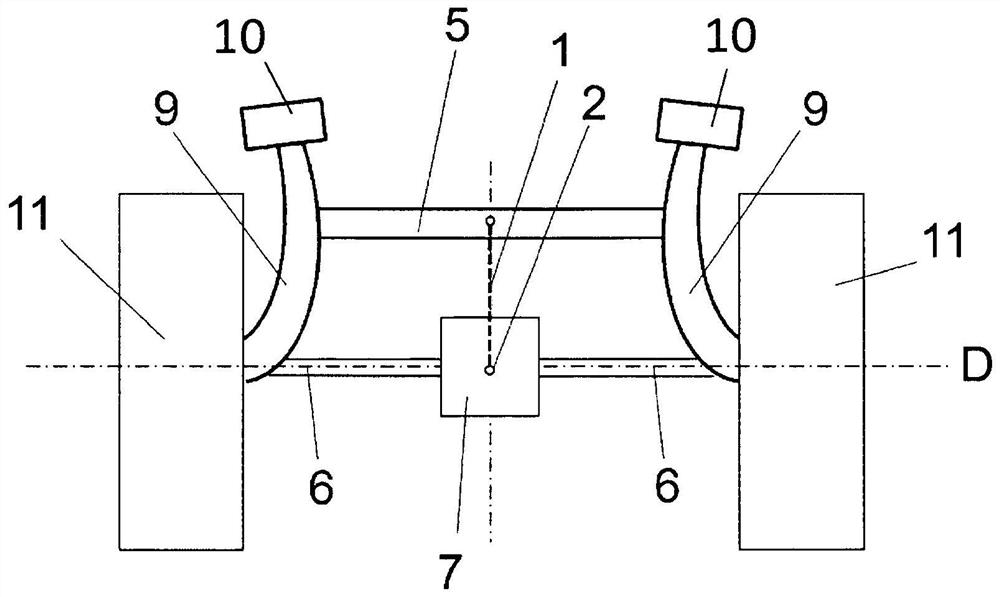

[0029] figure 1 The combined tie-rod axle of a vehicle according to the invention is described in a side view of the vehicle. Visible here is one of the two trailing arms 9 , a drive 7 , which drives at least one wheel 11 , which is guided by the combined tie-rod axle, via the drive shaft 6 . The transverse profile connecting the two trailing arms 9 is not shown in this view. Here, in the designed position, the drive unit 7 is supported on the body via bearings 4 directly adjacent to the common axis of rotation D and has a rotational degree of freedom about an axis parallel to the common axis of rotation D of the wheels 11 . According to the invention, said rotational degree of freedom is supported by a oscillating support 1 . In this case, the pivot support 1 is mounted via a bearing 2 on the drive 7 and via the other bearing 3 on the trailing rod 9 . During springing in and springing out, the drive device 7 is caused to perform a rotational movement about the vehicle tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com