Rotary valve

A technology for shutting down and switching fans, which is applied in the field of shutting down fans, and can solve the problems of poor sealing of the main body of the switch impeller, increased wear of the impeller blades, and easy leakage of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the examples.

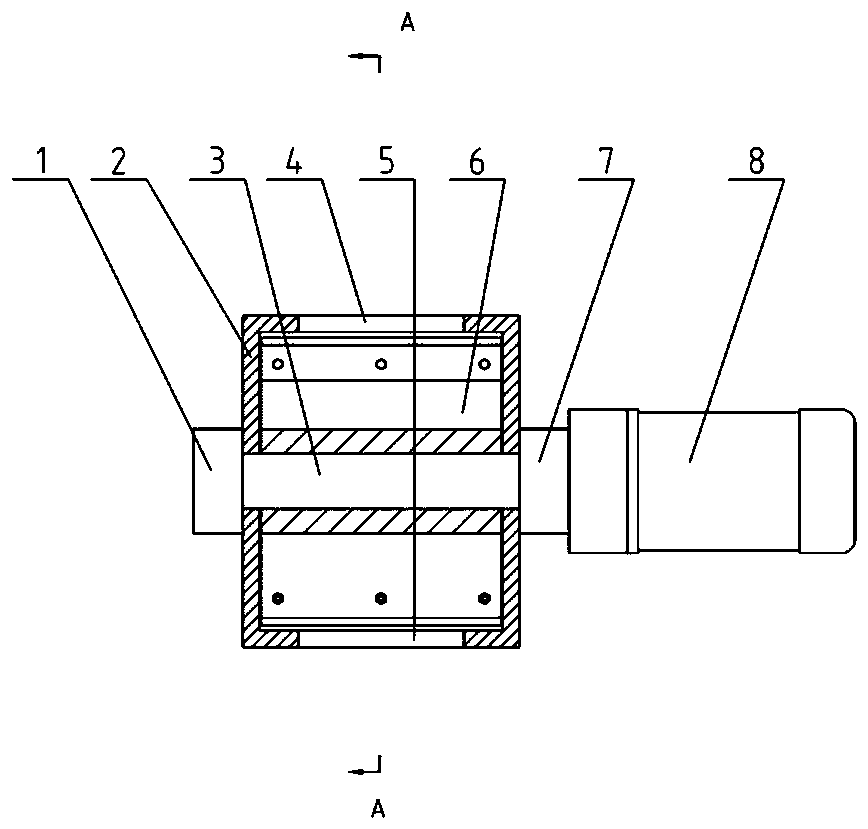

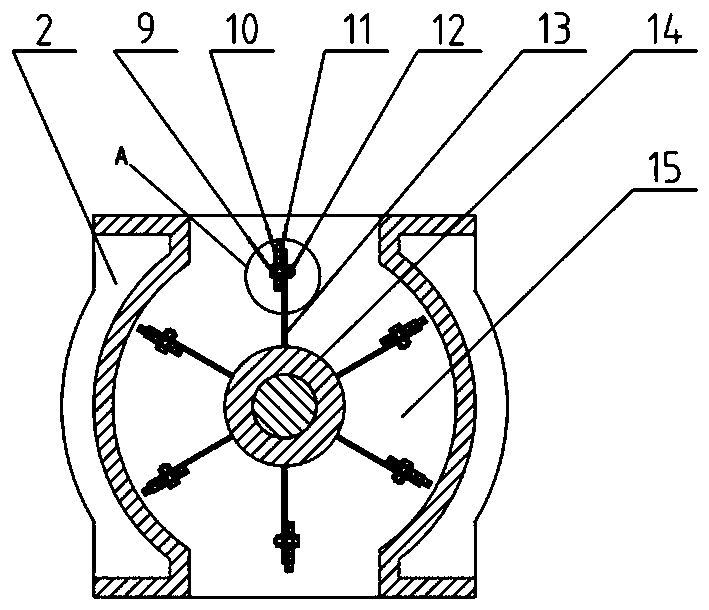

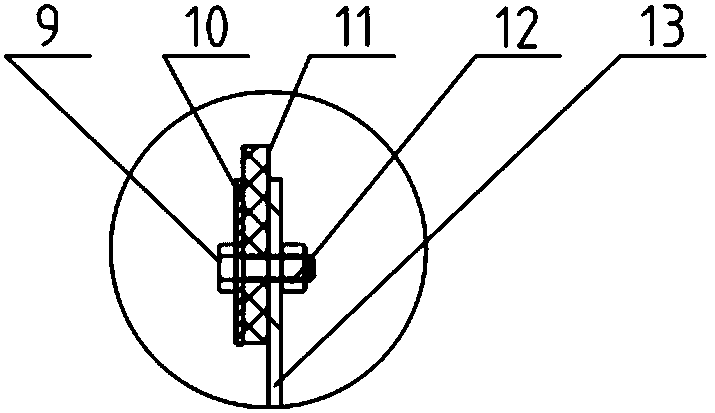

[0015] Such as figure 1 , figure 2 , image 3 Shown, be a kind of embodiment of the present invention, be provided with shut-off fan seat body 2, shut-off fan seat body 2 is provided with circular inner cavity body 15, and circular inner cavity body 15 upper end is provided with feed inlet 4, and circular inner cavity body The lower end of the cavity 15 is provided with a discharge port 5, the circular inner cavity 15 is provided with a switch impeller main body 6, the switch impeller main body 6 is provided with a power spindle 3, and the switch impeller main body 6 is provided with an impeller bushing 14 and an impeller blade 13 The outer side of the impeller blade 13 away from the impeller shaft sleeve 14 is provided with a sealing scraper 11 . The power spindle 3 is connected to the blower base body 2 through the left bearing seat 1 of the power spindle and the right bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com