Producing method of high-end shirt turn-down collar corners

A production method and technology of collar angle, which are applied in the field of clothing, can solve the problems that cannot be taken out, damage the fabric of the fabric, affect the appearance of the product and the quality of the product, etc., and achieve convenient removal of inserts, loose space, and convenient disassembly and installation of inserts. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

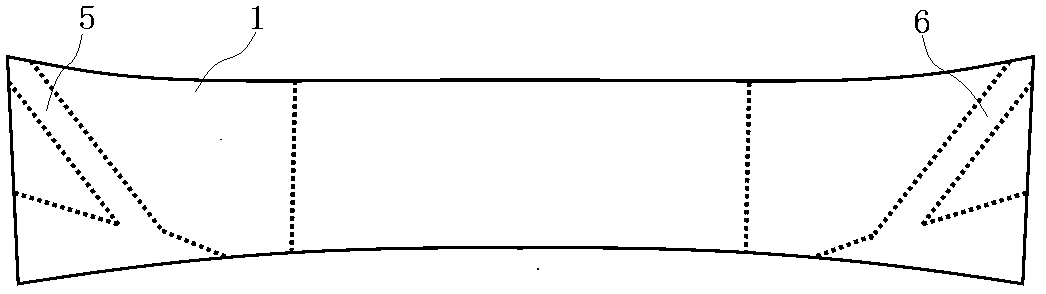

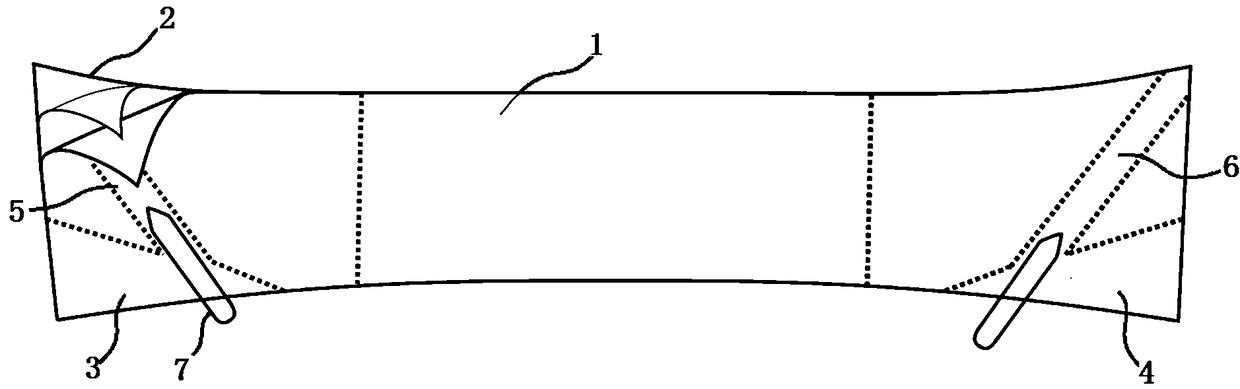

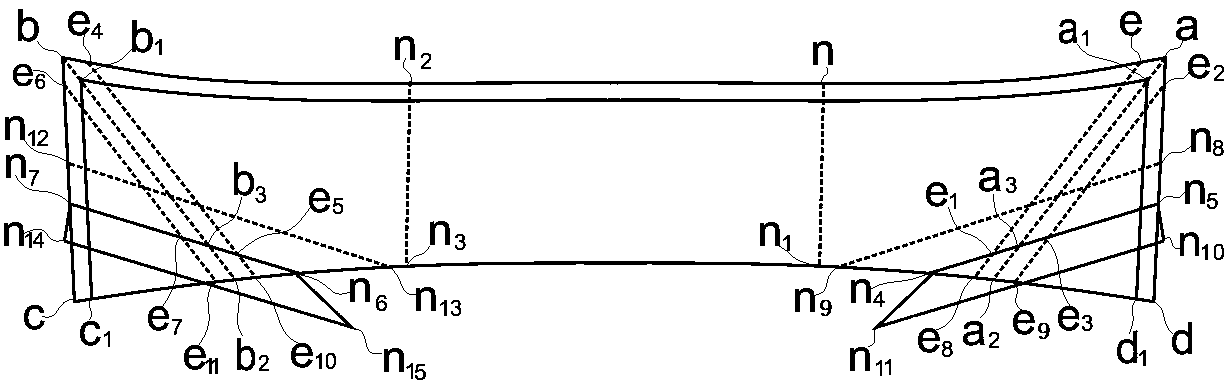

[0025] Such as Figure 1-5 as shown, image 3 The guiding line in the guideline refers to the intersection point between the two lines. The invention discloses a method for making a high-grade shirt lapel collar insert pocket. The left patch 3 and the right patch 4 between the two ends of the face 2; between the left end of the lapel 1 and the left patch 3, the left collar corner insert pocket 5 is arranged to be inclined inwardly along the left collar angle. Between the right end of the lapel 1 and the right patch 4, a right collar corner insert pocket 6 is arranged inwardly along the right collar corner, and inserted into the left collar corner insert pocket 5 and the right collar corner insert pocket 6 respectively. Sheet 7; the left patch 3 and the right patch 4 are symmetrically arranged, and the left collar corner insert bag 5 and the right collar corner insert pocket 6 are symmetrically arranged; the insert piece 7 is transparent plastic, and the insert piece 7 ends T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com