Silicone sealed mask

A mask and silica gel technology, applied in the field of masks, can solve the problems of poor sealing of the edges of masks, failure to conform to facial curvature characteristics, and inability to effectively play the role of dust and pollution prevention of masks, so as to achieve the effect of isolating dust and other pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

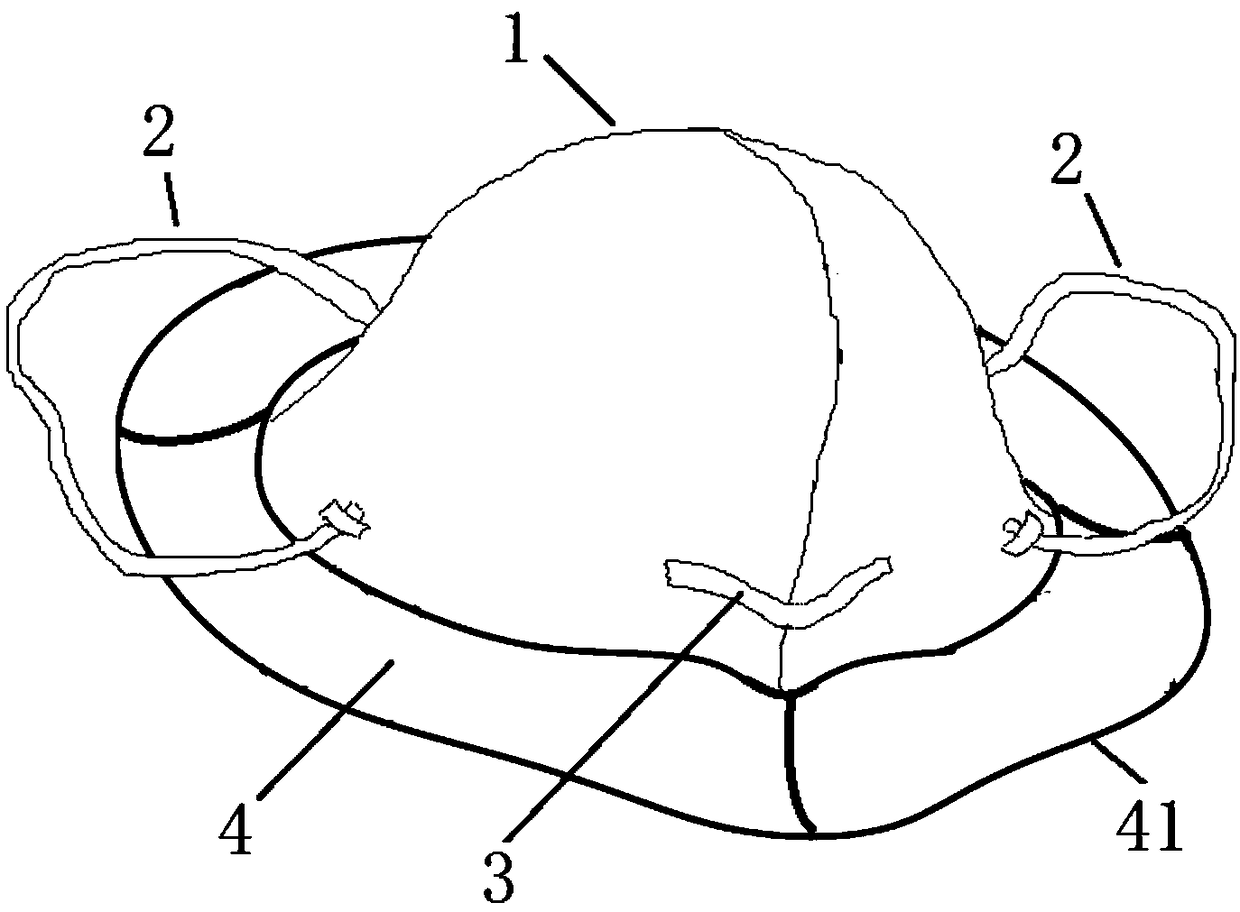

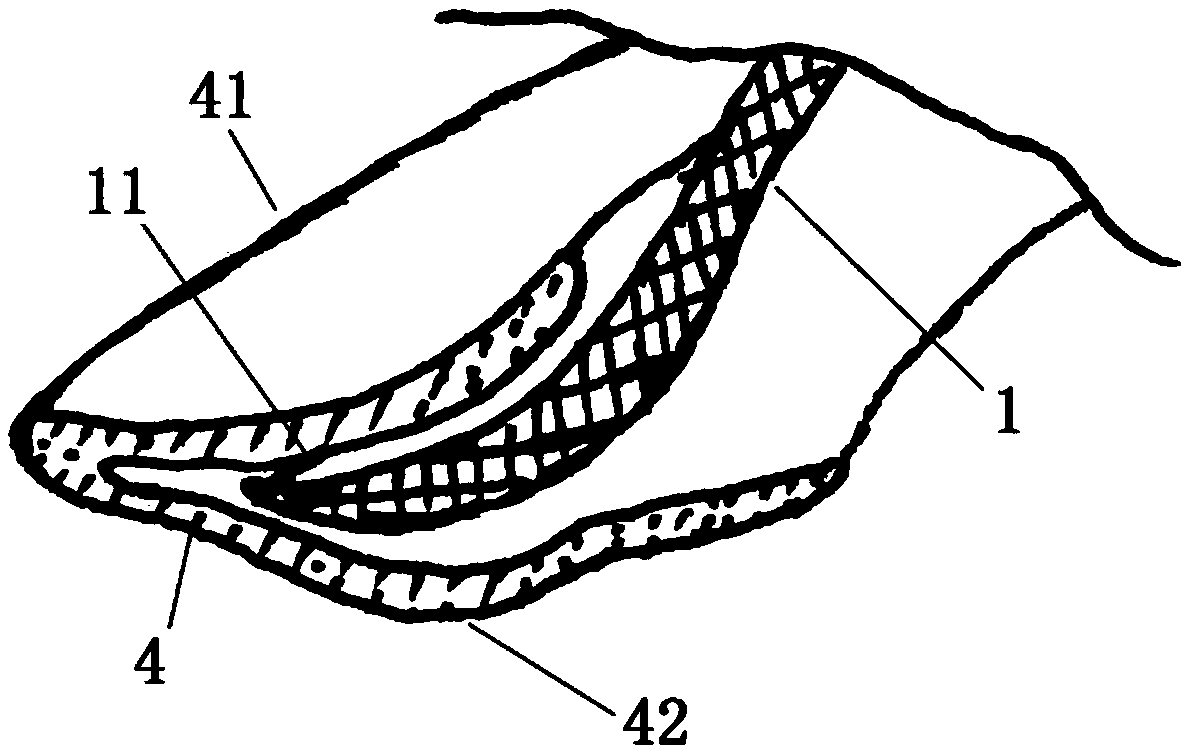

[0008] Such as figure 1 As shown, the present invention has a mask main body 1 and several restraint belts 2. A soft metal fitting strip 3 is provided at the position where the mask main body 1 fits with the bridge of the nose of the human body. It is characterized in that: there is also an annular silicone seal Circle 4, such as figure 2 As shown, its cross-sectional shape is a "<" type structure, and the "<" type section is swept along an annular sweep line 41 to form the overall structure of the sealing ring, and the annular sweep line 41 and the mask main body The edge line 11 of 1 is consistent; the annular silicone sealing ring 4 is set on the edge of the mask main body 1 through its "<" structure, and when the annular silicone sealing ring 4 is in contact with the human face The surface is set as a convex smooth transition surface 42 .

[0009] The above-mentioned specific embodiments are only exemplary, and are intended to better enable those skilled in the art to u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com