A kind of ceramic surface coloring method

A kind of ceramic surface and ceramic technology, which is applied in the direction of instruments, electric recording process equipment using charge graphics, optics, etc., can solve the problems of carbon powder leakage, inconvenient control of carbon powder addition, and inconvenient carbon powder disposal, etc., to achieve Prevents toner leakage, prevents accumulation, and is easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0028] Such as Figure 1 to Figure 6 Shown, a kind of ceramic surface coloring method of the present invention is characterized in that: the method comprises the steps:

[0029] Step 1: Coloring pigments are colored onto a plastic film by a laser printer to form a colorful pattern;

[0030] Step 2: After the color pattern is formed in step 1, stick the plastic film on the ceramic;

[0031] Step 3: After the plastic film is pasted on the ceramics in step 2, the ceramics are sintered at high temperature to achieve coloring;

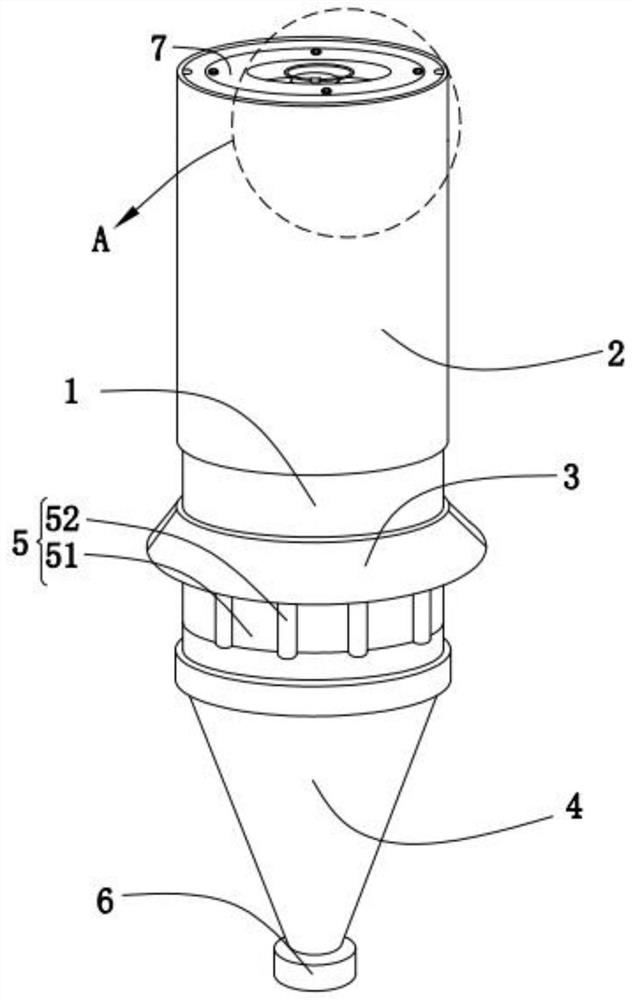

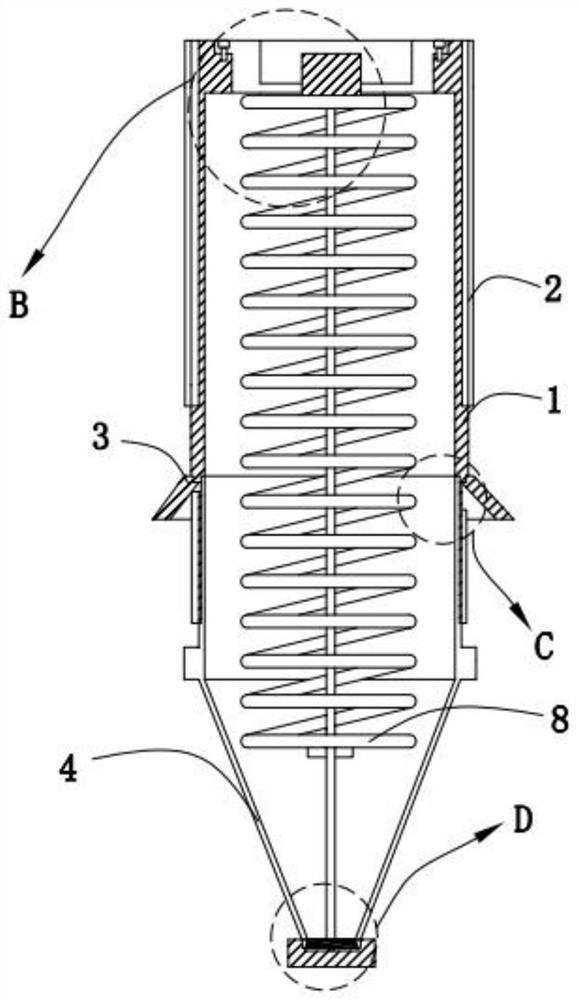

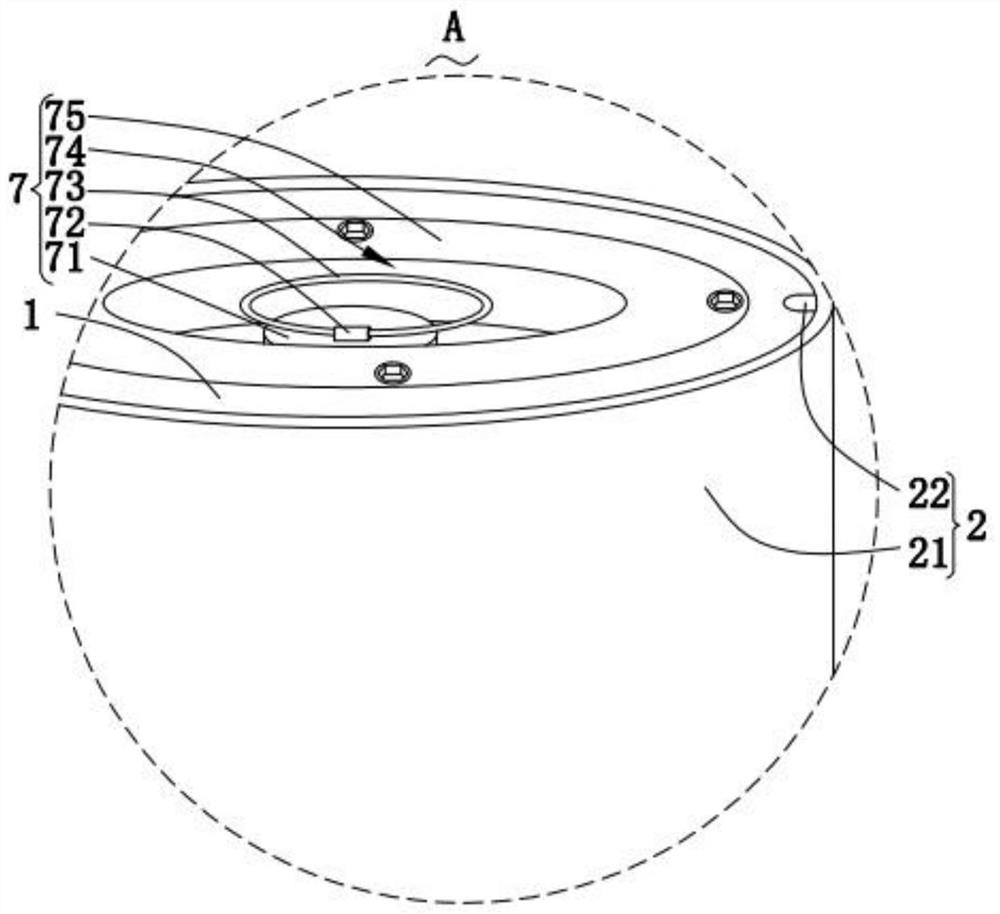

[0032]Wherein, the carbon powder box that described laser printer adopts comprises storage tube 1, flow-concentrating sleeve 3, guide sleeve 4, sealing end cap 6, driving structure 7, stirring rod 8 and limit structure 9; Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com