Foam adhesive tape as well as manufacturing method and application thereof

A manufacturing method and technology of cotton tape, applied in the direction of adhesive, film/flake adhesive, etc., can solve the problems of high cost, waste labor, time-consuming and other problems of grooving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

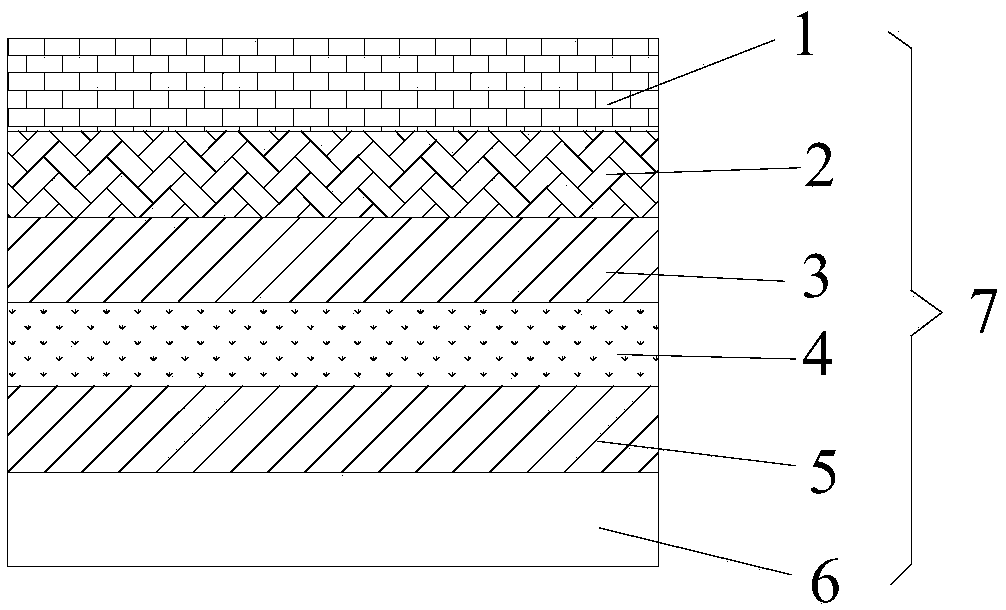

[0038] see figure 1 , a foam tape 7, including an easy-adhesive layer 1, a foam layer 2, a first pressure-sensitive adhesive layer 3, a flexible reinforcing layer 4, a second pressure-sensitive adhesive layer 5, and a release material layer 6 arranged in sequence.

[0039] The material of the easy-bonding layer 1 is PU primer M-T-18, and the thickness of the easy-bonding layer 1 is 0.005mm, which can increase the adhesion of the foam surface.

[0040] The foam layer 2 is PU foam, which is made of polyurethane resin through the foaming process on the release material layer 6, and the foaming density is 200kg / m 3 , the thickness of the foam layer 2 is 0.8mm.

[0041] The first pressure-sensitive adhesive layer 3 and the second pressure-sensitive adhesive layer 5 are formed by coating the peelable acrylate adhesive on the release material layer 6. The thickness of the first pressure-sensitive adhesive layer 3 is 0.06 mm, and the thickness of the first pressure-sensitive adhesive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com