Flexible and wearable force feedback production device and method for independent micro propeller traction

A technology for generating devices and propellers, which is applied in the input/output process of data processing, the input/output of user/computer interaction, instruments, etc. or pull soft effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

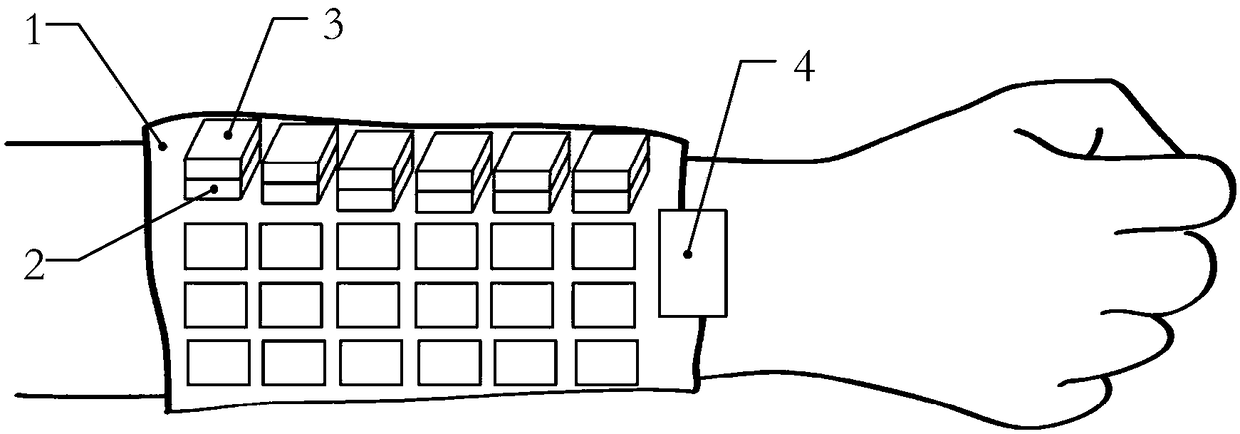

[0037] Such as figure 1 As shown, the specific implementation of the present invention includes a wearable fabric 1 and a central control module 4; the wearable fabric 1 is closely attached to the surface of the human body, the central control module 4 is fixed on the side of the wearable fabric 1, and the wearable fabric 1 is fixed with force feedback Generating components, the force feedback generating components are arranged in an array at intervals on the surface of the wearable fabric 1 , and the force feedback generating components are connected to the central control module 4 . The wearable fabric 1 can be worn on people's chest, back, neck, arms, fingers, legs and other parts.

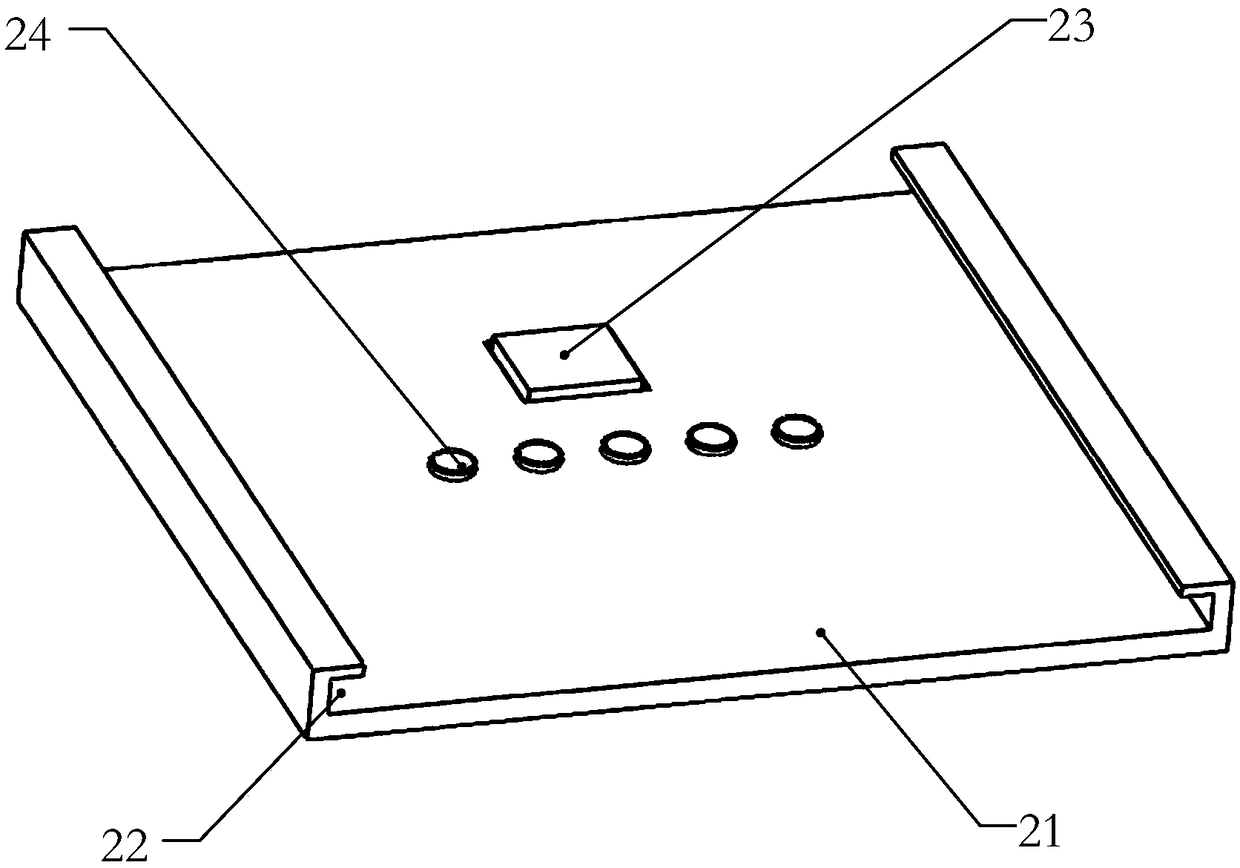

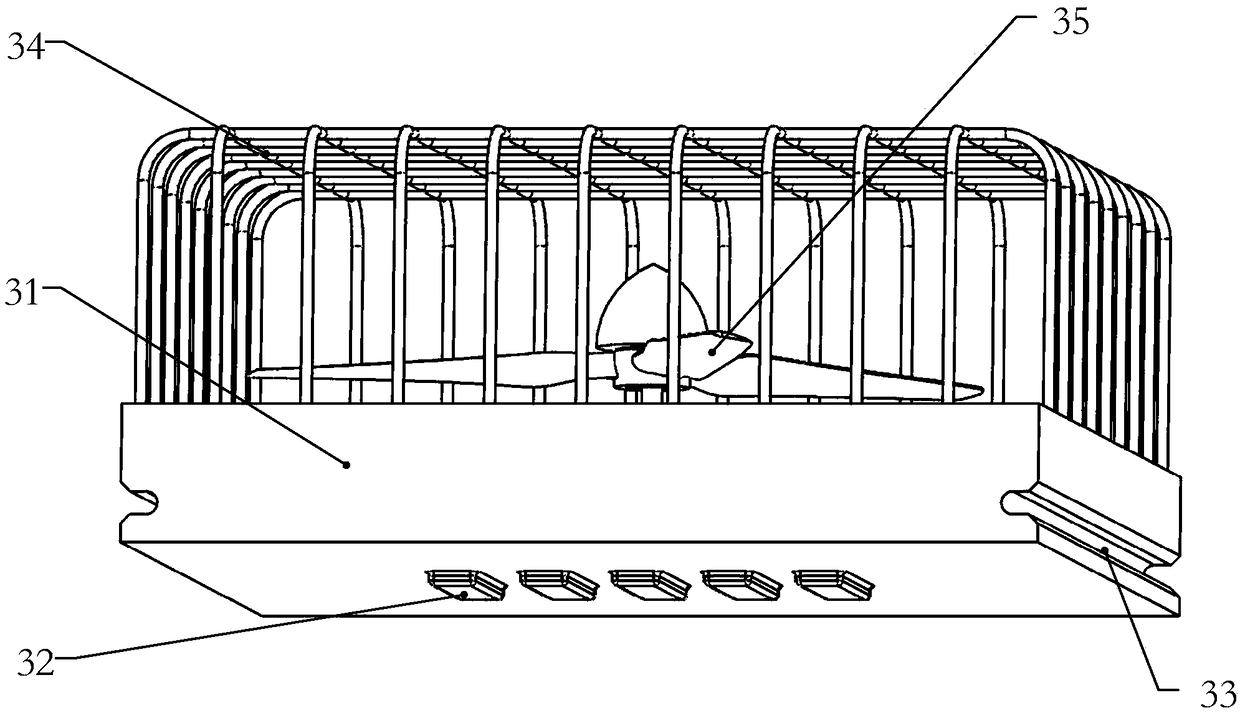

[0038] The force feedback generating assembly includes a support module 2 and a miniature propeller traction module 3 installed on the support module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com