golf club head

A golf club head and hitting surface technology, applied to golf balls, golf clubs, rackets, etc., can solve the problems of increasing production cost, increasing the difficulty of manufacturing process, weakening the performance of the club head, etc., and achieving strong tactile feedback Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

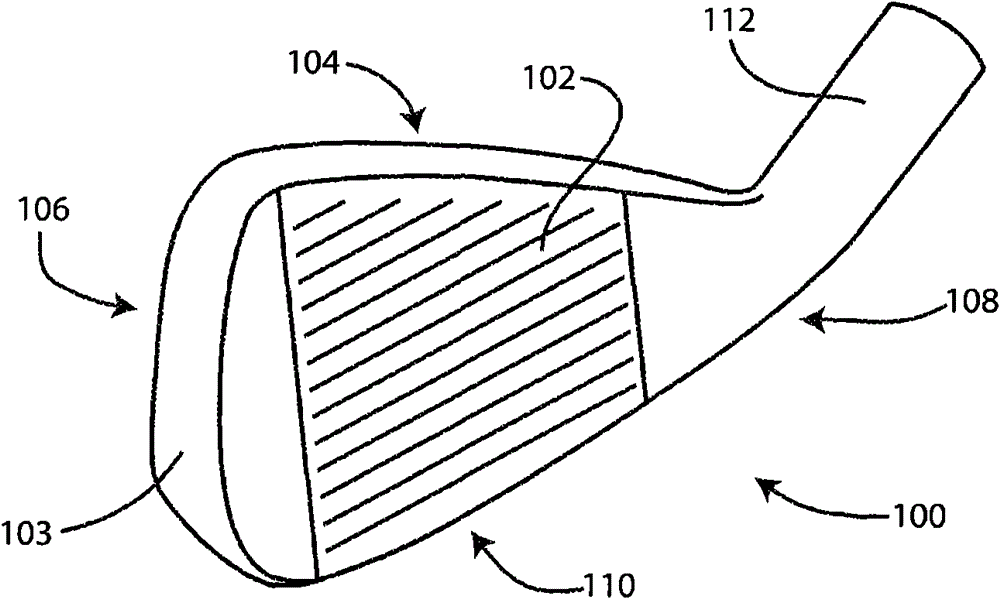

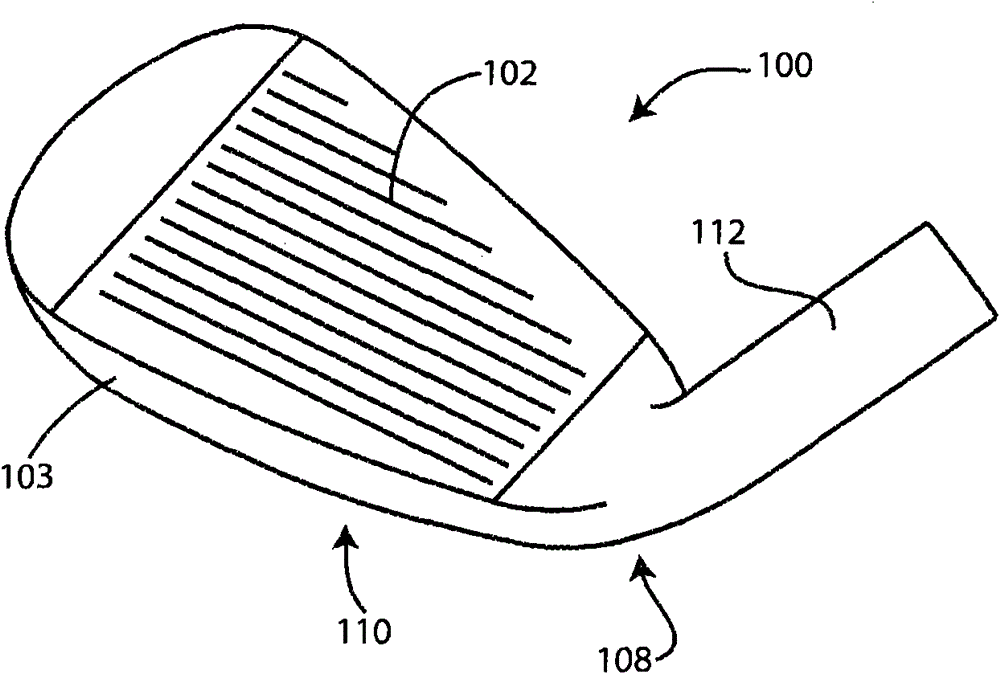

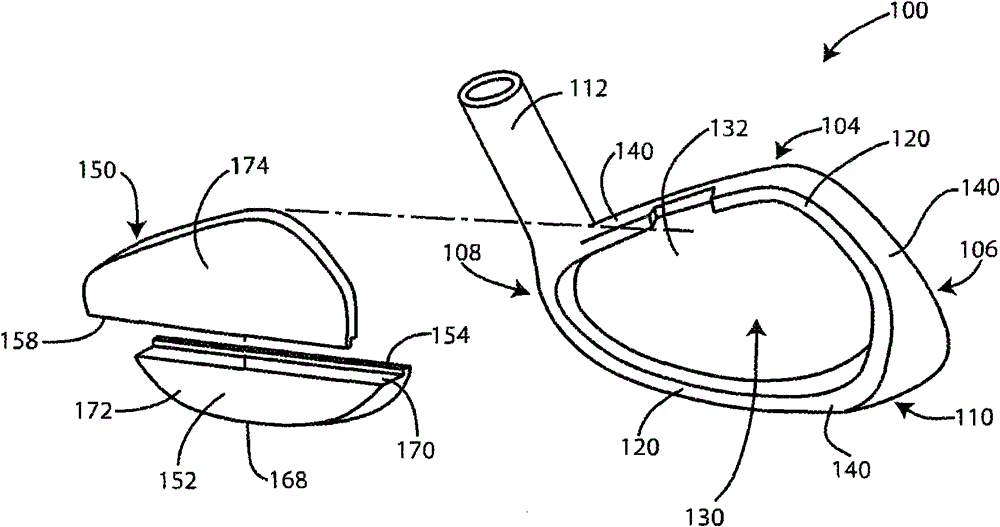

[0033] see Figure 1a and Figure 1b In accordance with one or more aspects of the present invention, golf club head 100 generally includes a ball striking face 102 , a body 103 (having a top line 104 ), a toe 106 , a heel 108 and a sole 110 . The ball striking face 102 may be integrated into the body 103, or may be attached to the body 103 by mechanical interlocking, welding, brazing, or adhesive. A snap opening 112 extends from the body 103 for receiving a club shaft (shaft not shown). like Figure 1c As shown, the club head 100 also includes a main cavity 130 limited in extent by a back wall 132 surrounding it and at least partially limited by a peripheral weight 140 (including the rear surface 120). The back wall 132 is located behind the ball striking face 102 . Materials suitable for making golf club head 100 include, for example, carbon steel, stainless steel, 6-4 titanium alloy, 10-2-3 Beta-C titanium alloy, 6-22-22 titanium alloy, and the like.

[0034] like Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com