Speed reducing device for preventing traveling in reverse direction

A technology of deceleration device and deceleration belt, which is applied in the directions of roads, road signs, traffic signals, etc., can solve problems such as inability to correctly control vehicles, collision with public equipment, panic of wheel drivers, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

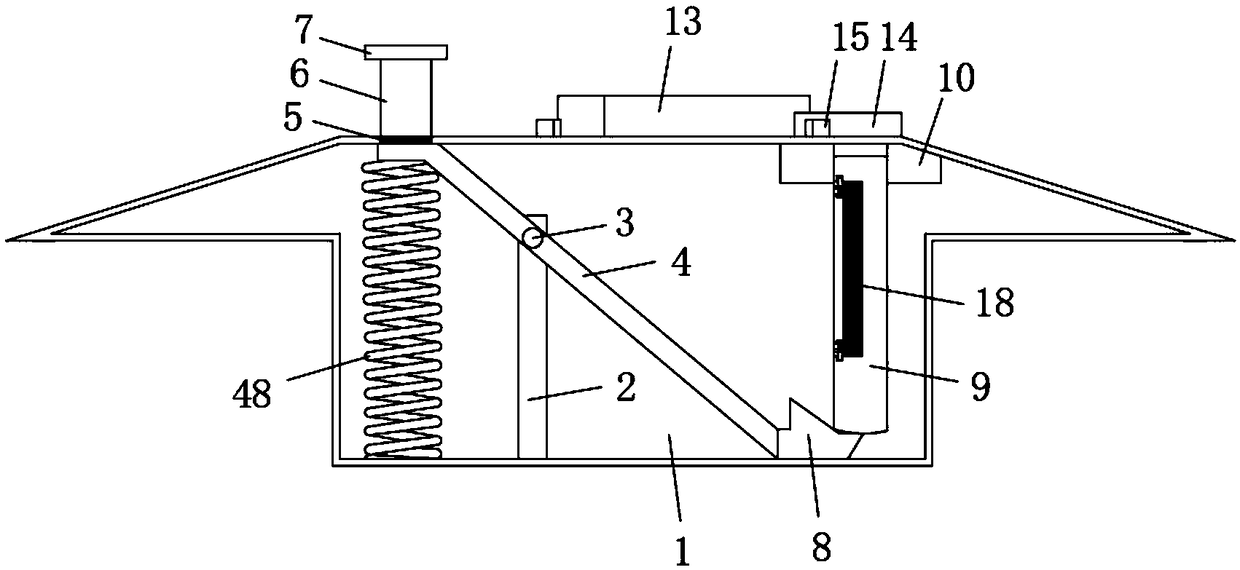

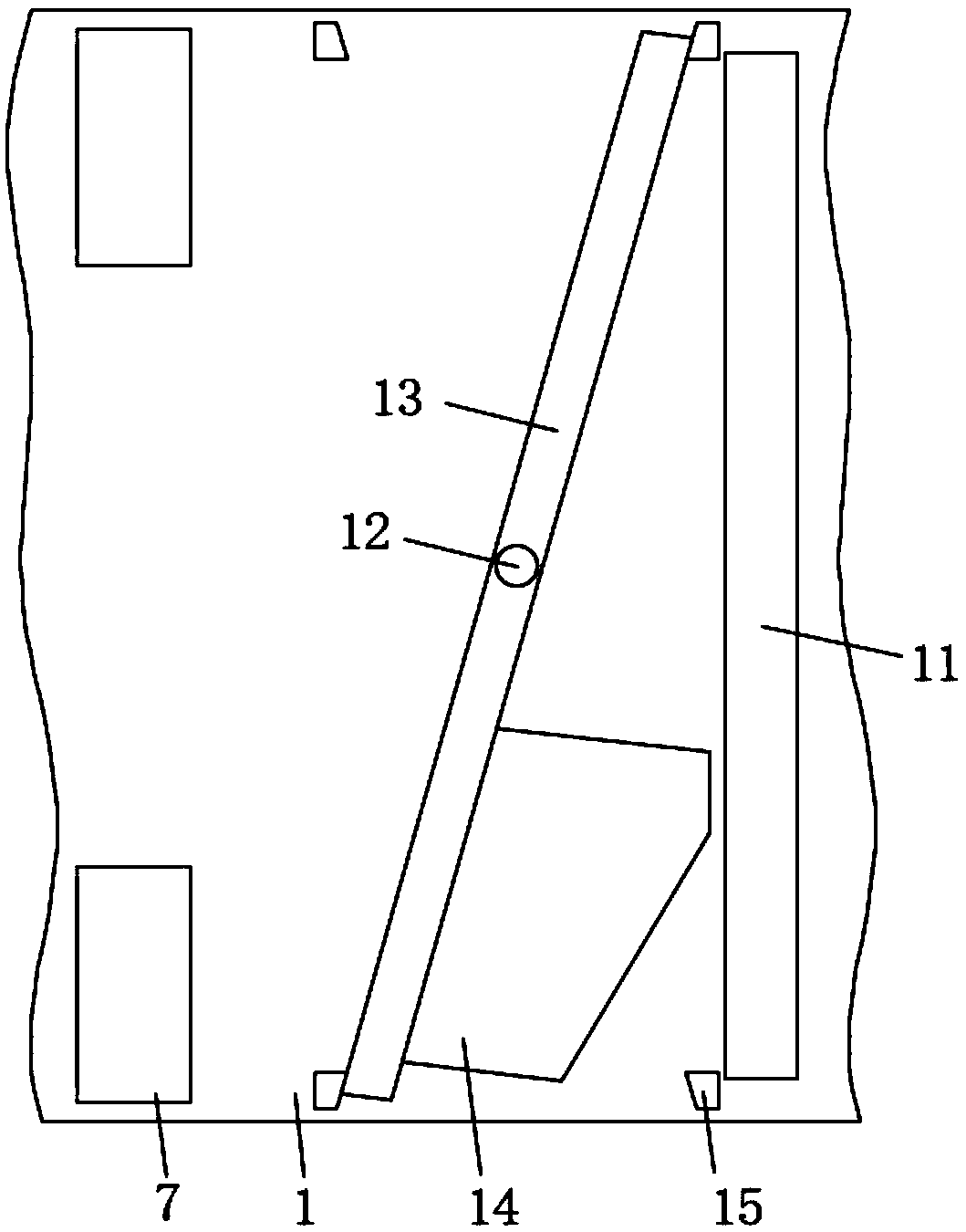

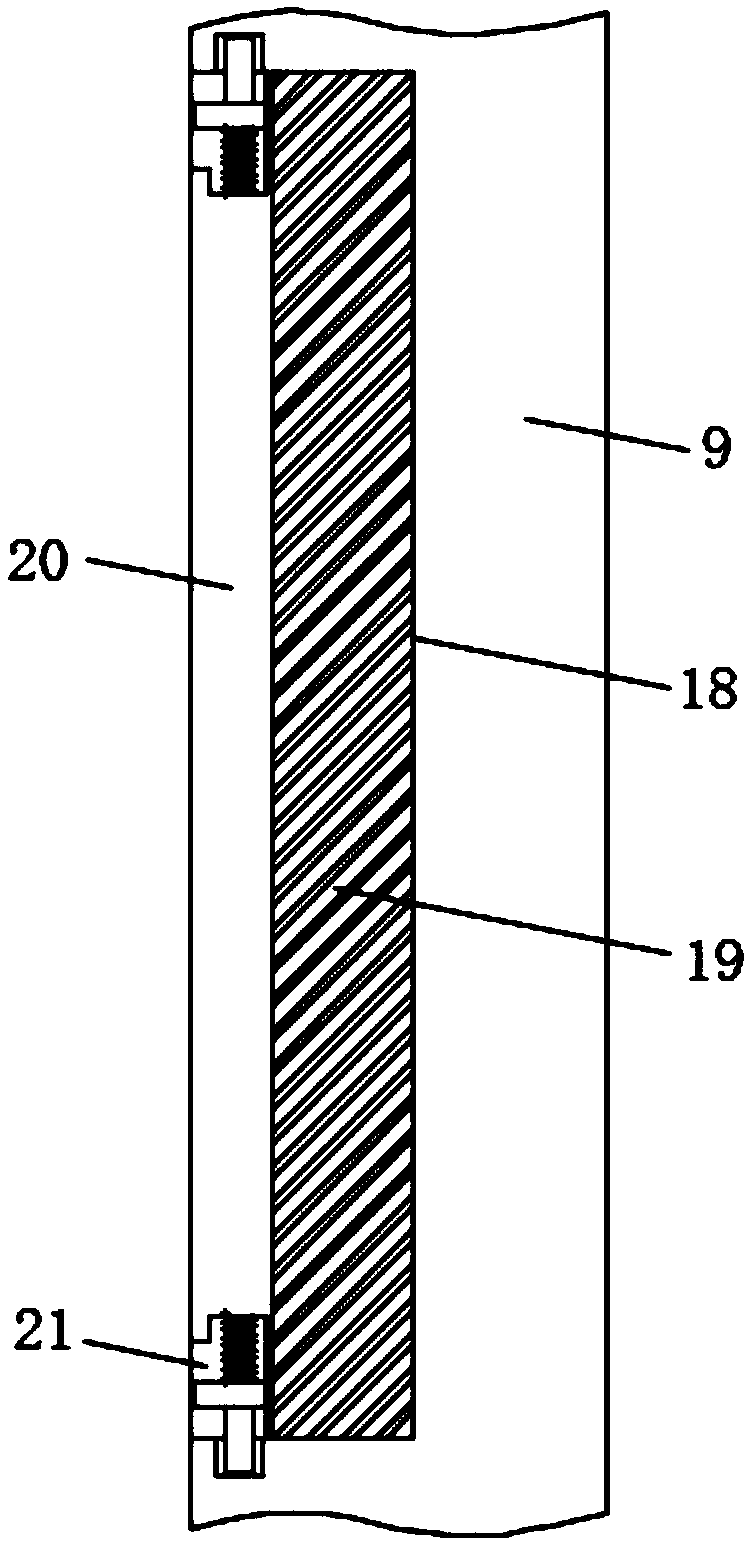

[0033] refer to Figure 1-5 , the anti-reverse deceleration device, including the deceleration belt 1, the interior of the deceleration belt 1 is symmetrically fixedly connected with two turrets 2, the two turrets 2 are jointly rotated and connected with the first rotating shaft 3, and the first rotating shaft 3 is fixedly connected with Rotate the lever 4, and the first rotating shaft 3 runs through the rotating lever 4, one end of the rotating lever 4 is provided with a rubber block 5, the upper end of the rubber block 5 is fixedly connected with a pressing rod 6, and the upper end of the pressing rod 6 runs through the inner wall of the speed reduction belt 1 and The pressing plate 7 is fixedly connected, and the vertical height between the pressing plate 7 and the deceleration belt 1 is one-third of the normal wheel, so that the pressing plate 7 will not contact and affect other parts of the vehicle during the forward process. The other end of the lever 4 is fixedly connec...

Embodiment 2

[0038] refer to Figure 6-9 The difference between this embodiment and Embodiment 1 is that the shielding structure includes a pressure sensor 26, a gear motor 27, a first rotating shaft 28, a first helical gear 29, a second helical gear 30, a second rotating shaft 31, a bar Magnet 32, support frame 33, baffle plate 34, single magnetic pole 35, support plate 36, reinforcing rod 37 and controller 49, pressure sensor 26 is installed on the upper surface of deceleration belt 1, and pressure sensor 26 is positioned at the bar blind hole 11 On the right side, a reduction motor 27 and a controller 49 are installed inside the speed reduction belt 1. The driving end of the reduction motor 27 is fixedly connected with the first rotating shaft 28, and the first rotating shaft 28 is fixedly connected with the first helical gear 29, and the second A rotating shaft 28 runs through the first helical gear 29, the first helical gear 29 is meshed with a second helical gear 30, the second helic...

Embodiment 3

[0042] refer to Figure 10-13 The difference between this embodiment and Embodiment 1 and Embodiment 2 is that the shielding structure includes a second rotating shaft 31, a bar magnet 32, a baffle plate 34, a single magnetic pole 35, a support plate 36, a reinforcing rod 37, and a block 38 , turntable 39, second rotating rod 40, second fixed seat 41, second rotating shaft 42, first gear 43, second gear 44, mounting seat 45, mounting frame 46, reinforcing rib 47, the upper surface of deceleration belt 1 The turntable 39 is attached symmetrically, and the interior of the deceleration belt 1 is fixedly connected with a mounting seat 45, and the mounting seat 45 is rotatably connected with a second rotating shaft 31 through a bearing, and the second rotating shaft 31 is fixedly connected with a bar magnet 32 and a second gear 44. , and the second gear 44 is located above the bar magnet 32, the upper end of the second rotating shaft 31 passes through the second gear 44 and is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com