Tape guide device for gardening buncher

A guiding device and strapping technology, which is applied to the parts of strapping machinery, gardening, strapping materials, etc., can solve the problems of time-consuming, strapping back, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

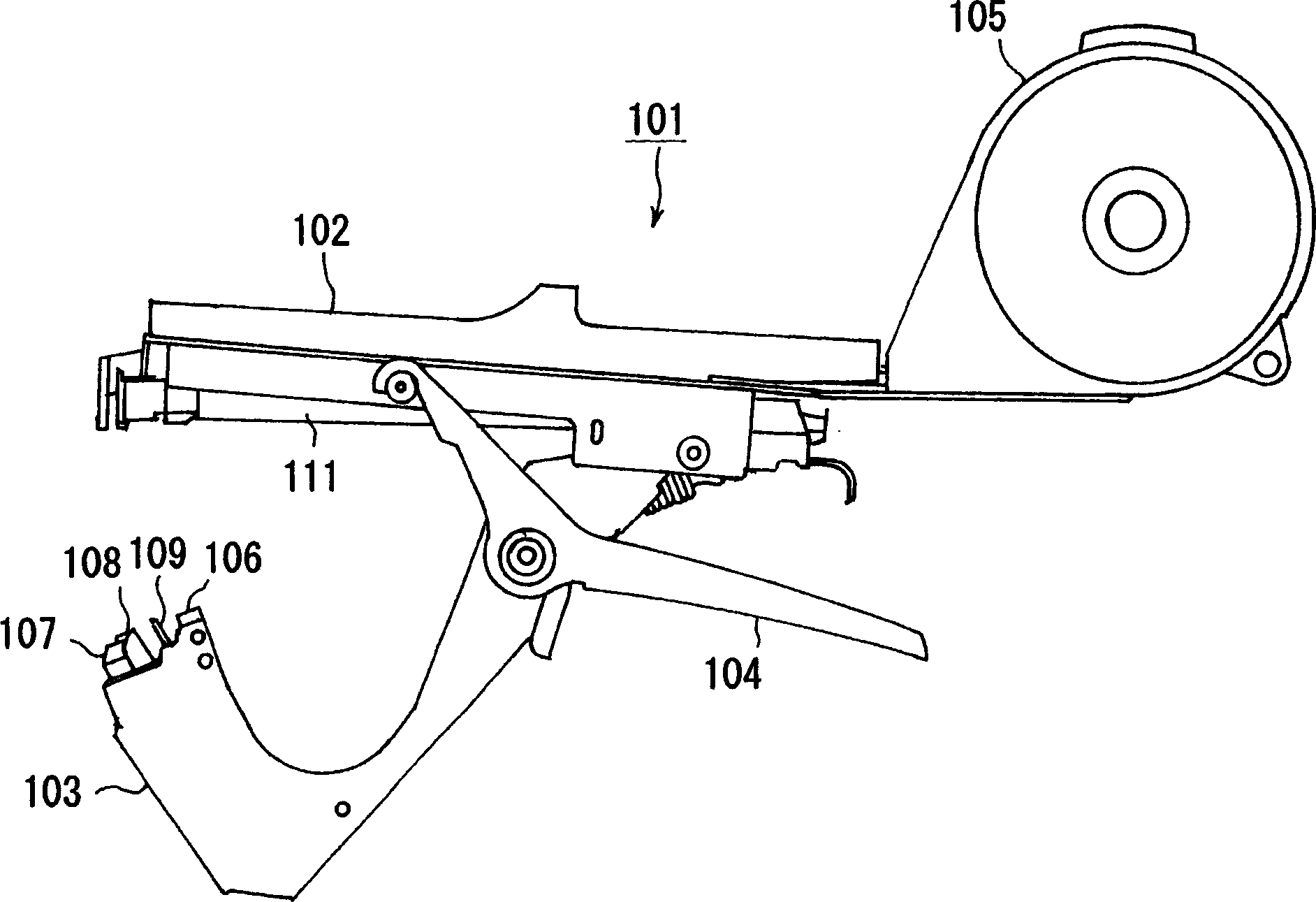

[0037] The first embodiment of the present invention will be described in detail below with reference to the accompanying drawings. First, the overall structure and operation of the garden binding machine of this embodiment will be described. figure 1 Shown is a gardening strapping machine 101, which is composed of a driving handle 102, a pincer arm 103 and a lower handle 104 in a pincer shape. Pull out the strap from the front end of the drive handle 102.

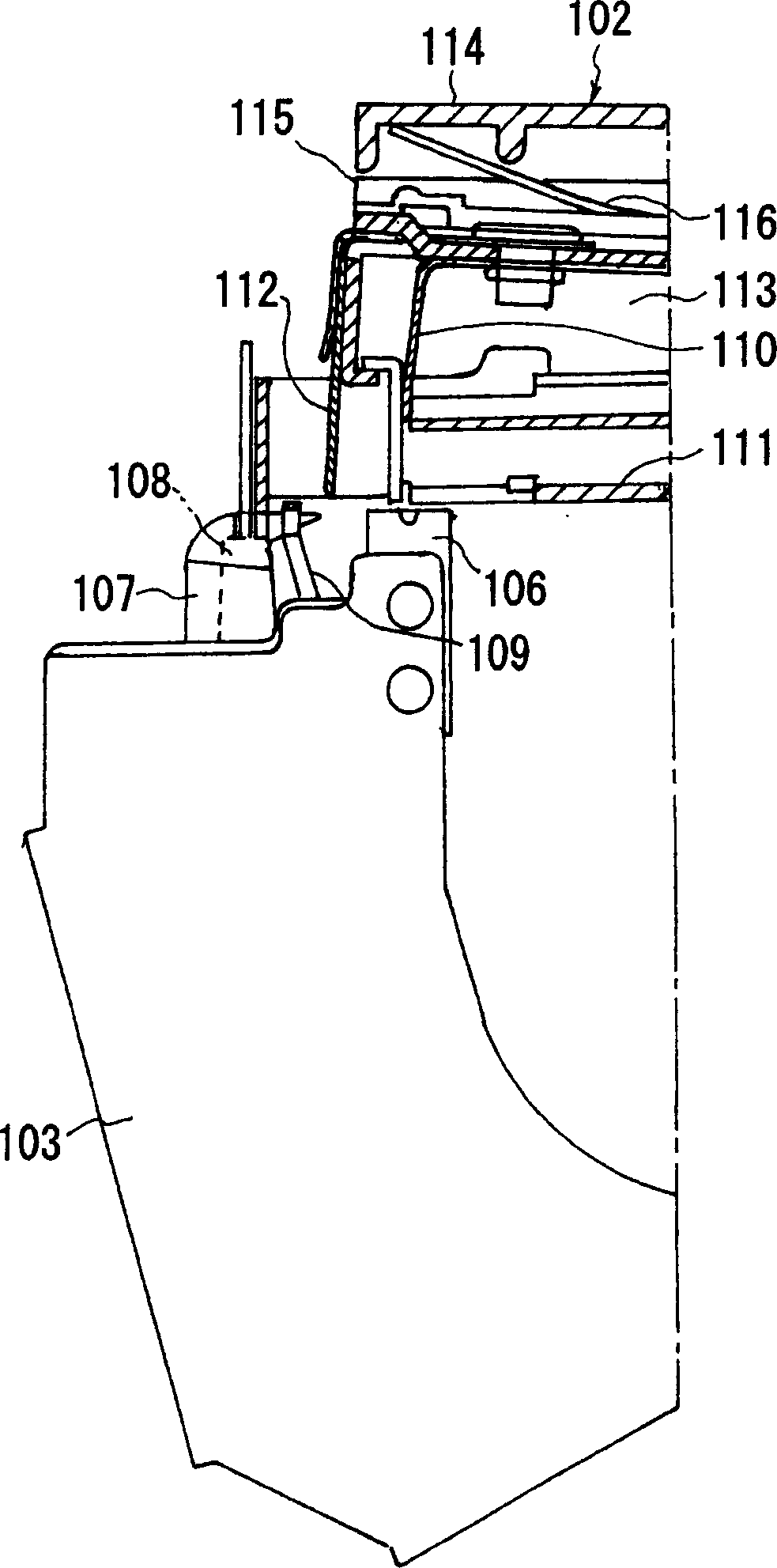

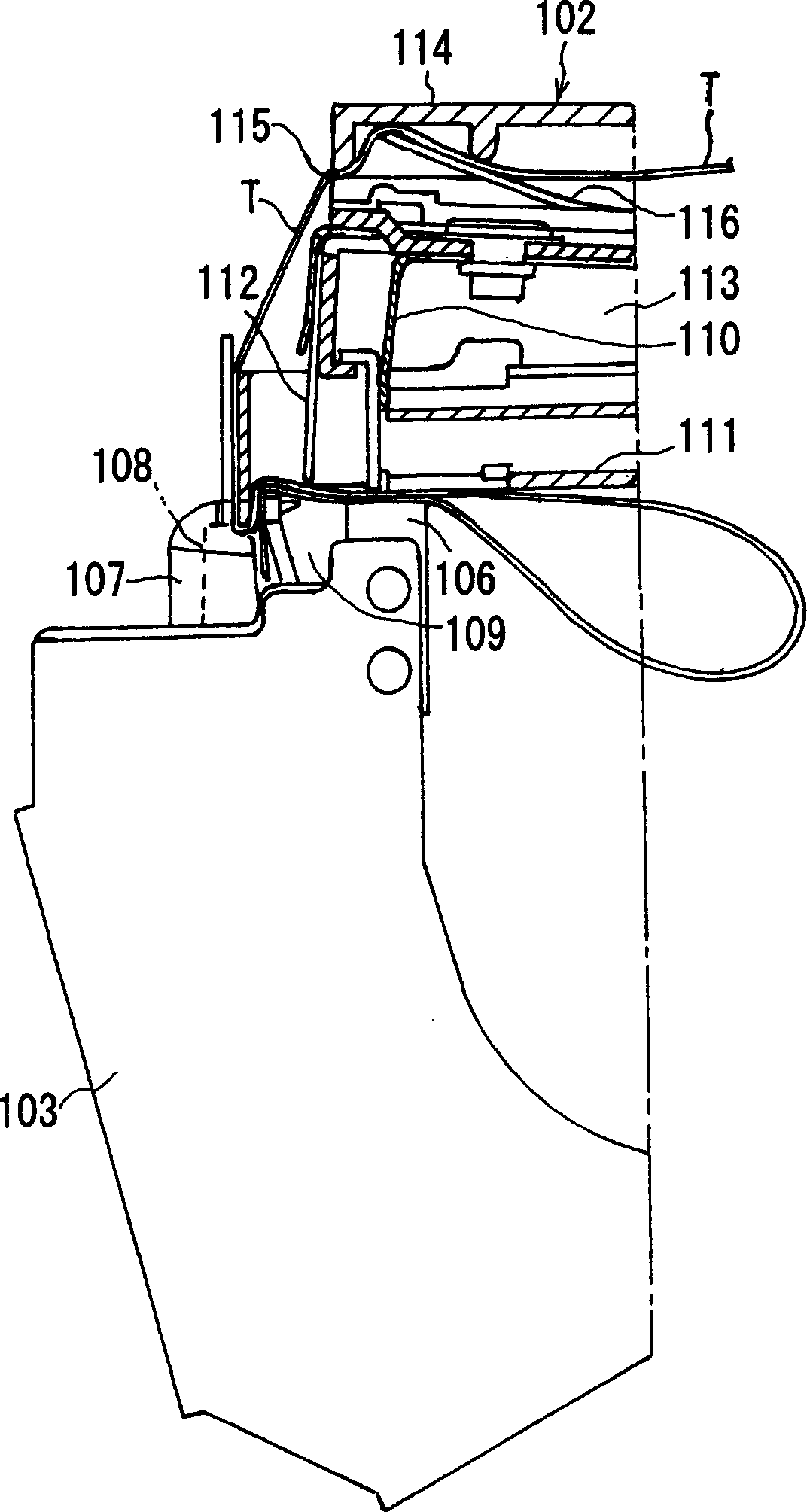

[0038] Such as figure 2 As shown, a jaw 106 is installed at the front end of the pincer arm 103, and a strap holding device that combines the piercing plate 107, the pressing plate 108 and the fixed flange plate (not shown) is arranged slightly in front of the jaw 106. . Although the illustration is omitted, the needles piercing the plate 107 are embedded in the grooved flanges of the pressing plate 108 that can slide up and down freely and the grooved flanges of the fixed flange plate. Press down, then by the coordina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com