A kind of cathode material for liquid flow battery and preparation method thereof

A flow battery and composite material technology, applied in battery electrodes, fuel cells, regenerative fuel cells, etc., can solve the problems of unfavorable flow battery cycle performance and insufficient stability of fluid electrodes, and achieve the suppression of shuttle effect, good fluidity and Electrochemical performance, the effect of improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

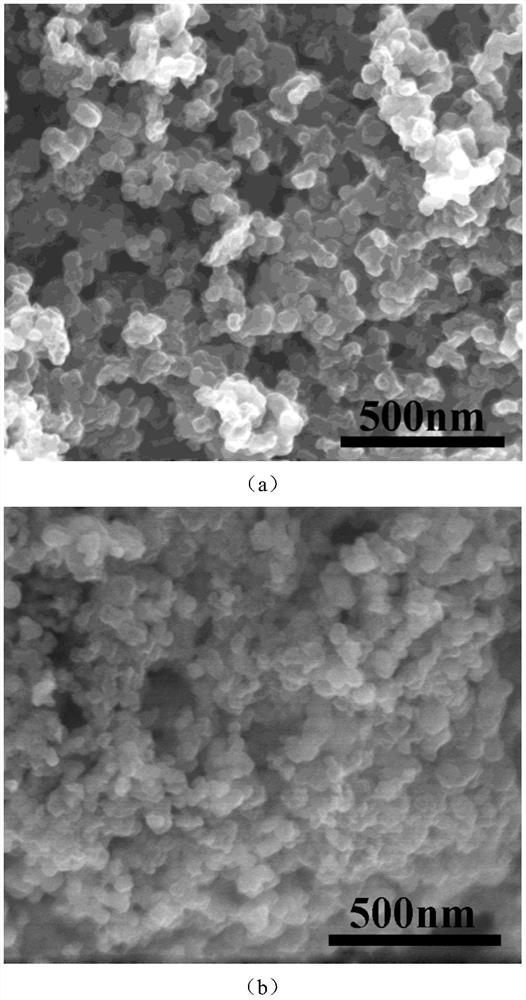

[0052] The sulfur-Ketjen black-graphene composite material of the present embodiment comprises a graphene layer and sulfur and Ketjen black arranged between the graphene layers; specifically, the multilayer graphene layer and the Ketjen black arranged between the graphene layers Black forms a three-dimensional network structure of carbon, and sulfur is evenly distributed in the three-dimensional network structure of carbon; the mass ratio of sulfur, Ketjen black, and graphene is 0.896:0.05:0.05.

[0053] The preparation method of the sulfur-ketjen black-graphene composite material of the present embodiment comprises the steps:

[0054] 1) Add 0.05g Ketjen Black to 100mL water, ultrasonically disperse for 30min to disperse Ketjen Black evenly in water, then add 3.48g Na 2 S 2 o 3 ·5H 2 O dispersed evenly to Na 2 S 2 o 3 ·5H 2 O was completely dissolved, then slowly added 5.55 g of concentrated hydrochloric acid with a mass fraction of 36%, and then vigorously stirred for...

Embodiment 2

[0060] The sulfur-Ketjen black-graphene composite material of the present embodiment comprises a graphene layer and sulfur and Ketjen black arranged between the graphene layers; specifically, the multilayer graphene layer and the Ketjen black arranged between the graphene layers Black forms a three-dimensional network structure of carbon, and sulfur is evenly distributed in the three-dimensional network structure of carbon; the mass ratio of sulfur, Ketjen black, and graphene is 0.64:0.03:0.02.

[0061] The preparation method of the sulfur-ketjen black-graphene composite material of the present embodiment comprises the steps:

[0062] 1) Add 0.03g Ketjen Black to 100mL water, ultrasonically disperse for 30min to disperse Ketjen Black evenly in water, then add 2.48g Na 2 S 2 o 3 ·5H 2 O dispersed evenly to Na 2 S 2 o 3 ·5H 2 O was completely dissolved, then slowly added 5.55 g of concentrated hydrochloric acid with a mass fraction of 36%, and then vigorously stirred for ...

Embodiment 3

[0068] The sulfur-Ketjen black-graphene composite material of the present embodiment comprises a graphene layer and sulfur and Ketjen black arranged between the graphene layers; specifically, the multilayer graphene layer and the Ketjen black arranged between the graphene layers Black forms a three-dimensional network structure of carbon, and sulfur is evenly distributed in the three-dimensional network structure of carbon; the mass ratio of sulfur, Ketjen black, and graphene is 1.28:0.1:0.1.

[0069] The preparation method of the sulfur-ketjen black-graphene composite material of the present embodiment comprises the steps:

[0070] 1) Add 0.1g Ketjen Black to 150mL water, ultrasonically disperse for 30min to disperse Ketjen Black evenly in water, then add 4.96g Na 2 S 2 o 3 ·5H 2 O dispersed evenly to Na 2 S 2 o 3 ·5H 2 O was completely dissolved, then slowly added 5.55 g of concentrated hydrochloric acid with a mass fraction of 36%, and then vigorously stirred for 6 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com