Small-power motor

A low-power, positioning convex technology, used in electrical components, electromechanical devices, electric components, etc., can solve the problems of shortened motor service life, increased noise, increased vibration, etc., to achieve long service life, low noise, and easy connection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

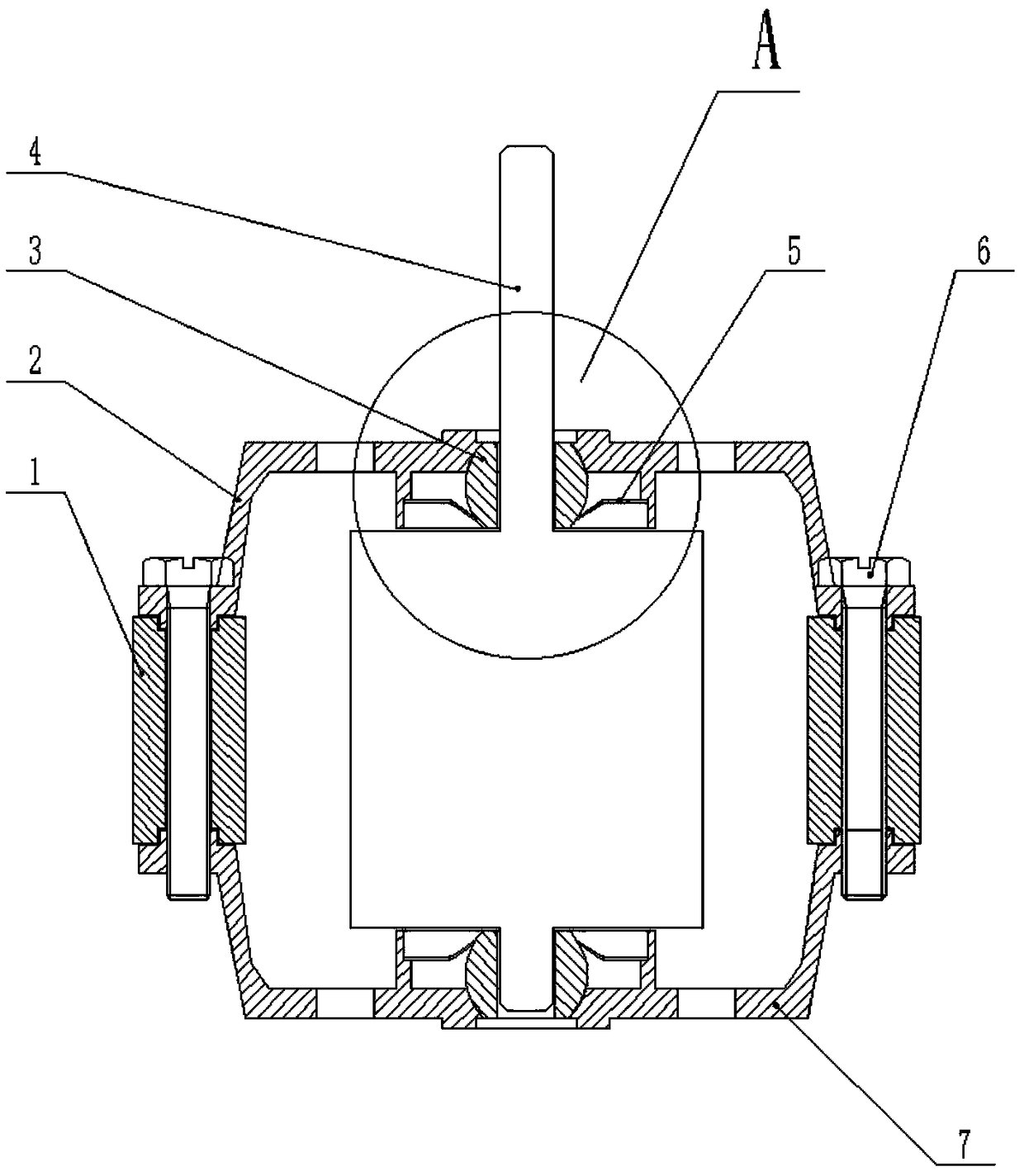

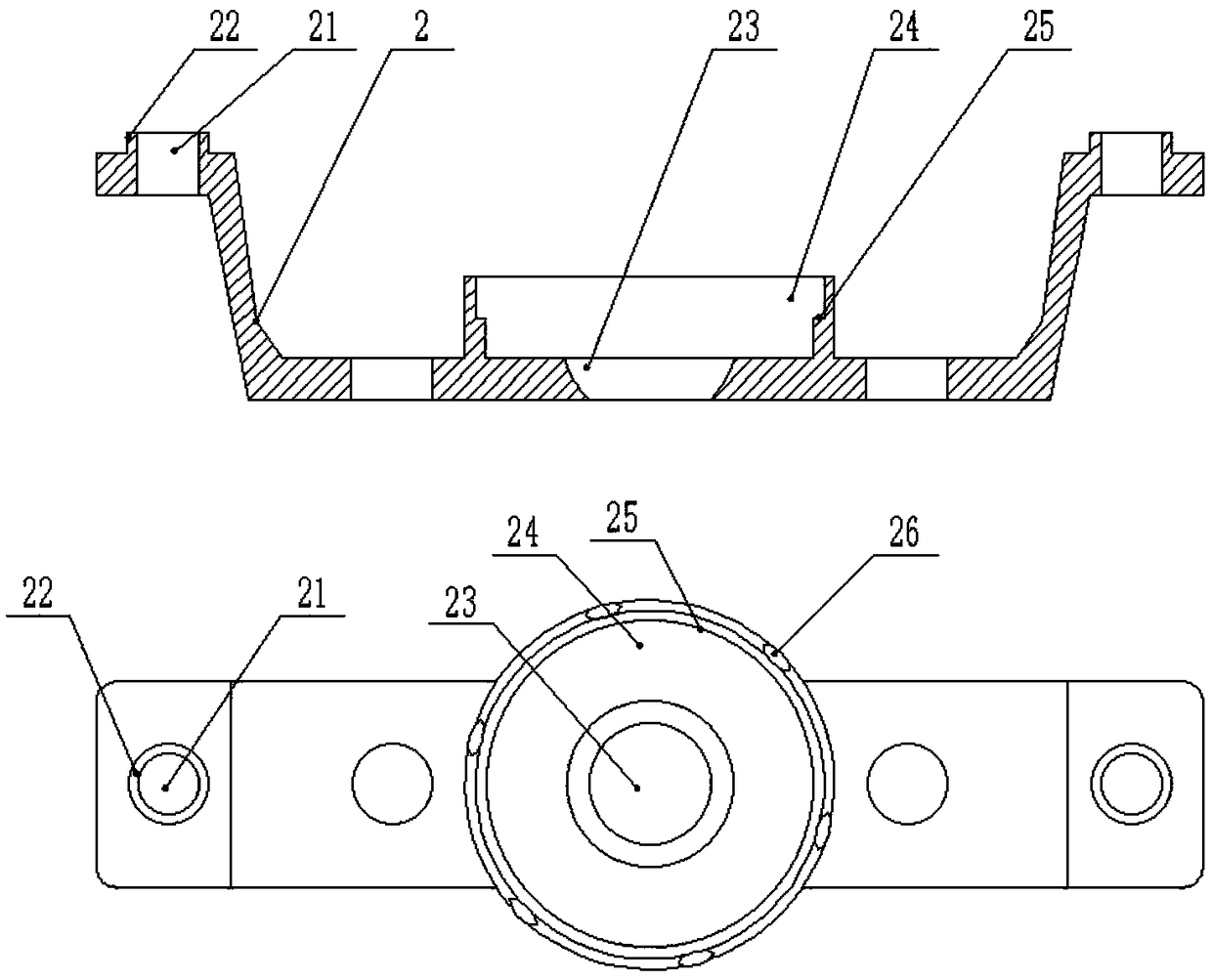

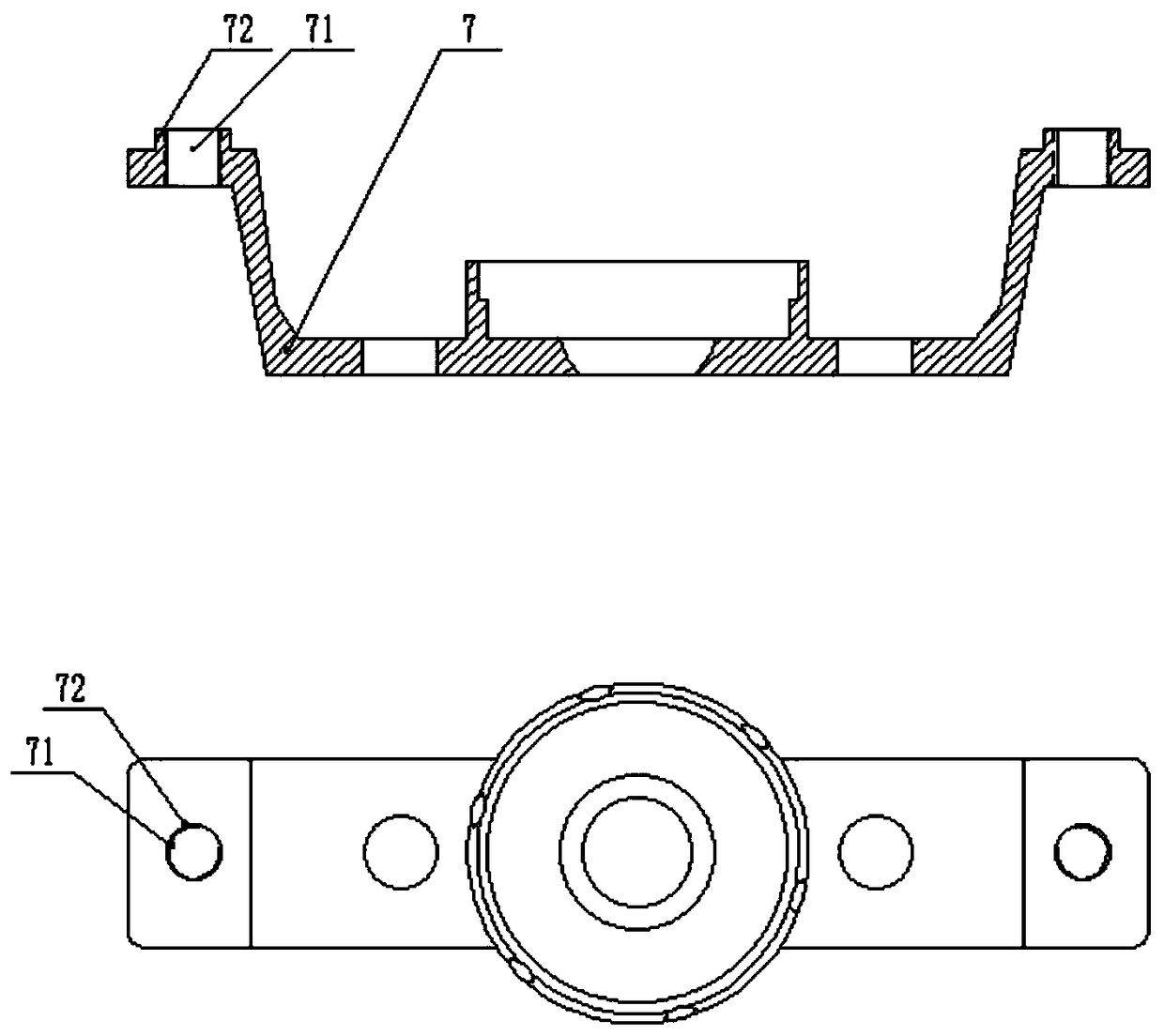

[0025] As shown in the figure, a low-power motor described in the embodiment of the present invention includes: figure 2 As shown, the two ends of the upper cover 2 process through holes 21 and upper positioning shoulders 22; image 3 As shown, the two ends of the lower cover 7 process threaded holes 71 and lower positioning shoulders 72; figure 2 As shown, the middle parts of the upper cover 2 and the lower cover 7 are all processed with a spherical shaft sleeve positioning hole 23 and a counterbore 24, and the counterbore 24 is a sinking shoulder 25, and the circumference of the counterbore 24 is also processed with a riveting groove 26, as Figure 7 As shown, the spherical bushing 3 is installed in the positioning hole 23 of the spherical bushing and is equipped with an elastic retainer 5, and the elastic retainer 5 is limited by the sinking shoulder 25 and the riveting groove 26, as Figure 4 As shown, the elastic blocking piece 5 is a circular sheet, and the middle par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com