A flue gas dust removal and desulfurization tower and dust removal and desulfurization method

A desulfurization tower and flue gas technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve problems such as difficulty in meeting emission standards, low efficiency of demisters in flue gas desulfurization devices, strong visual impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

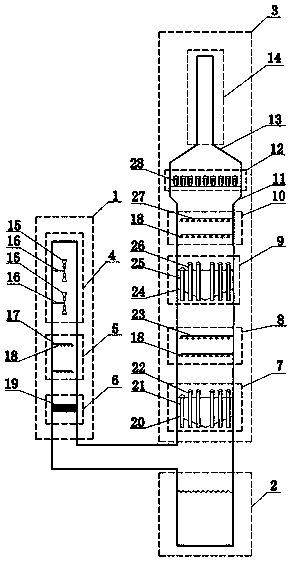

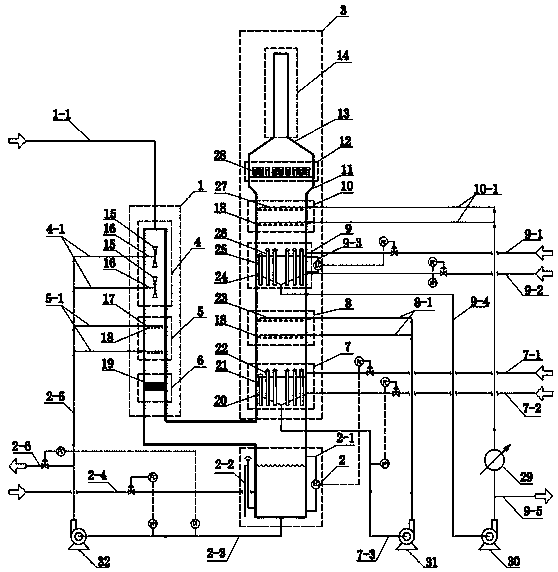

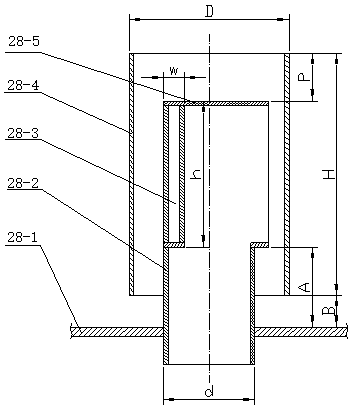

[0089] A flue gas dust removal and desulfurization tower, comprising a pretreatment unit 1, an advanced treatment unit 3, and a liquid holding tank area at the bottom of the tower. The pretreatment unit 1 and the advanced treatment unit 3 are connected through a flue gas pipeline, and the three constitute a "single-shaped" structure . The pretreatment unit 1 includes the quench spray area 4, the primary spray area 5, and the Venturi grid washing area 6 from top to bottom; the advanced treatment unit 3 includes the middle liquid holding tank area 7, and the secondary spray area from bottom to top. Shower area 8, upper liquid holding tank area 9, three-stage spray area 10, demister area 12, and flue gas discharge area 14.

[0090] The top of the quench spray area 4 is connected to the flue gas pipeline 1-1. The quench spray area 4 is provided with two layers of spray pipelines I 16. The distance between the spray pipelines I 16 is 2m, and the spray pipeline I 16 is provided with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com