A desulfurization device and flue gas dust removal, desulfurization and wastewater treatment method

A desulfurization device and wastewater treatment technology, which is applied in the fields of desulfurization and wastewater treatment, desulfurization devices, and flue gas dust removal, can solve the problems of equipment and boiler space that cannot be upgraded, shut down or demolished and rebuilt, and have too many equipment, so as to reduce equipment investment and Operating costs, reduced energy consumption, and high dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

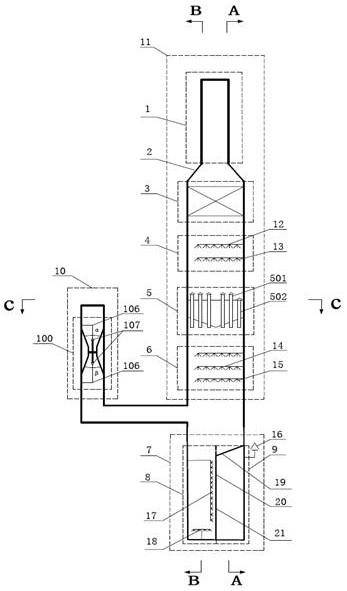

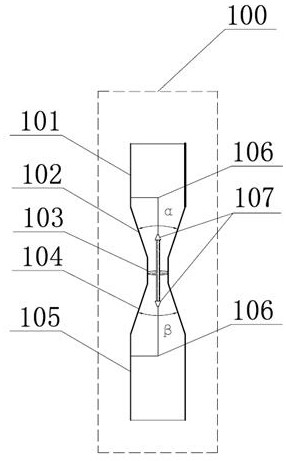

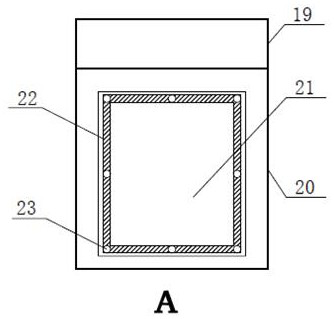

[0089] The flue gas temperature of an enterprise is 150 °C, the pressure is 4kPa, and the flow rate is 250,000 Nm 3 / h, where SO 2 The concentration is 1000 mg / Nm 3 The dust concentration is 280mg / Nm 3 , using the desulfurization apparatus of the present invention, as attached Figures 1 to 2 As shown, the diameter of the pretreatment unit 10 is 3m, the pretreatment unit 10 is provided with a venturi tube 100, the venturi tube 100 of the inlet straight tube section 101 and the outlet straight tube section 105 is round, the diameter is 3 m, the throat section is round, the diameter is 1.5 m, the length of the throat tube is 2 m, the cone angle of the shrinkage section α and the cone angle of the diffusion section are β are 15 °, the venturi tube 100 is provided along the axial direction of a set of nozzles, the vertical spacing of the two nozzles is 3 m, The diameter of the deep treatment unit 11 and the wastewater treatment unit 7 is 7m, and the chimney of the flue gas discharge zo...

Embodiment 3

[0095] The desulfurization apparatus of the present invention, a schematic structural diagram of the pretreatment unit 10 as follows Figures 5 to 6 As shown, the pretreatment unit 10 diameter is 3m, the pretreatment unit 10 is provided with 9 venturi tubes 100, venturi tube 100 inlet straight tube segment 101 and outlet straight tube segment 105 is a square with a side length of 0.7 m, the throat section is round, the diameter is 0.5 m, the length of the throat tube is 1 m, the cone angle of the shrinkage section α and the cone angle β of the diffusion section are 15 °, venturi tube 100 is provided along the axial direction of a set of nozzles, the vertical spacing of the two nozzles is 2 m, the rest of the same as Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com