Hobbing cutter outside bearing position

A bearing position and hob technology, applied in the field of mechanical tools, can solve the problems of smaller spindle bearing position, larger inner ring, and difficult maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

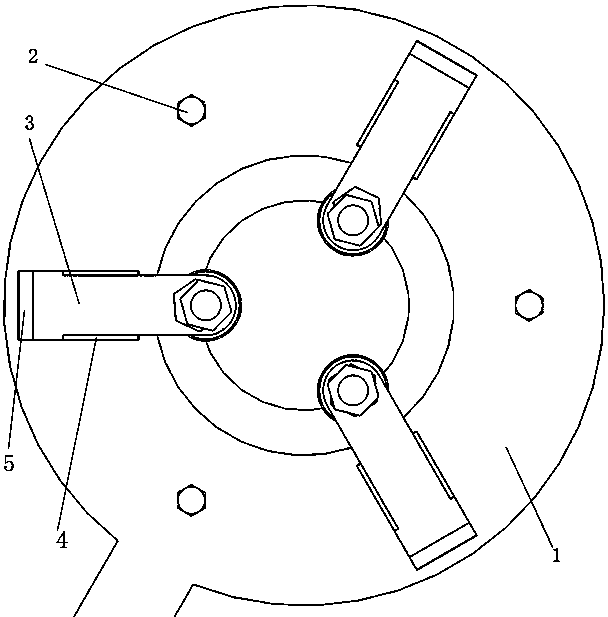

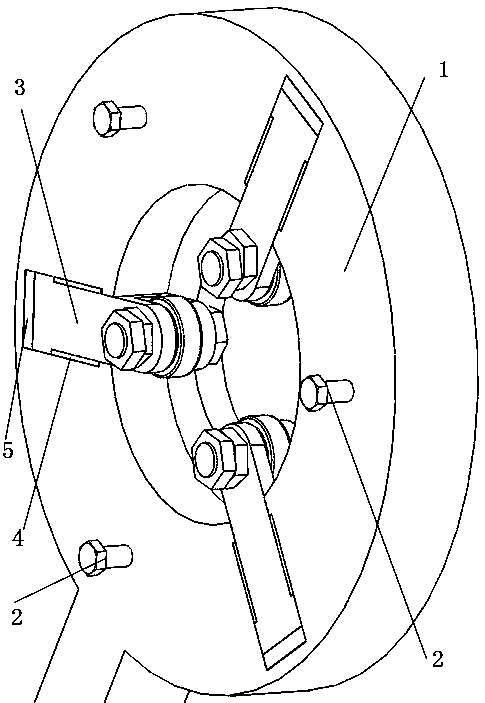

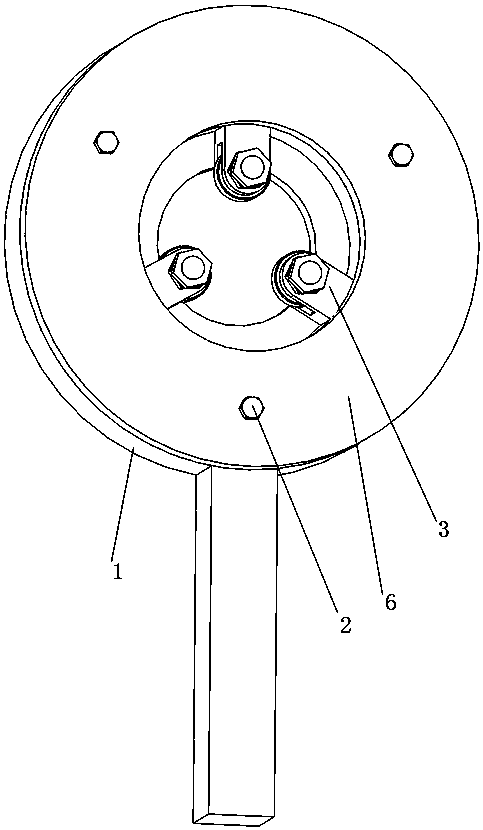

[0027] The applicant explained with reference to the accompanying drawings,

[0028] In the standard of domestic bearings, the inner diameter is incremented by 5mm. For example, the inner diameter of 6206 and 6306 is 30.00mm, the inner diameter of 6207 and 6307 is 35.00mm, and the inner diameter of 6308 and 6208 is 40.00mm. In the interference fit , the set tolerance is +0.02mm, then the corresponding spindle bearing dimensions are 30.02mm, 35.02mm and 40.02mm, therefore, the radii are 15.01mm, 17.51mm and 20.01mm respectively, if the size H2 of the standard block 1 is 20.00 mm, 22.50mm and 25.00mm, the size H4 of standard block 2 is 12.50mm, 15.00mm and 17.50mm, the size of H3 is 10.00mm, then the size of H1 is 10.00+12.50+25.00 or 10.00+15.00+22.50 or 10.00 +20.00+17.50, the results are both 47.50, the H2 size of the standard block 1 is 20.00mm, the H4 size of the standard block 2 is 17.50mm, just processed 6308, through the measurement, the spindle bearing position size is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com