Special plate making method for anti-copying

An anti-copying and special technology, which is applied in the printing, printing, and printing process of producing special varieties of printed matter, can solve the problems of complicated preparation process and high cost, and achieve the effect of simple and fast preparation process and simple anti-counterfeiting means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

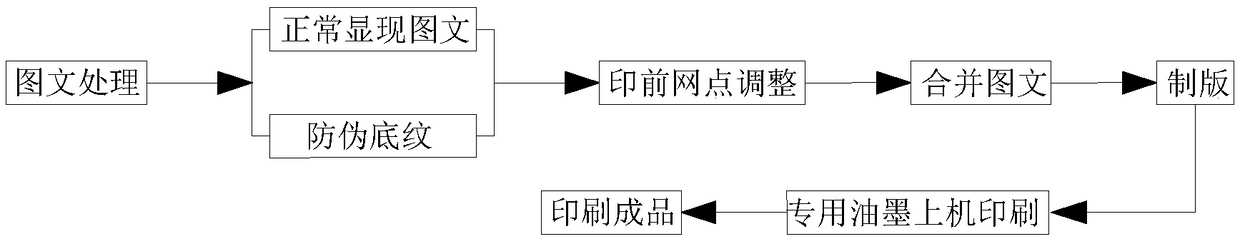

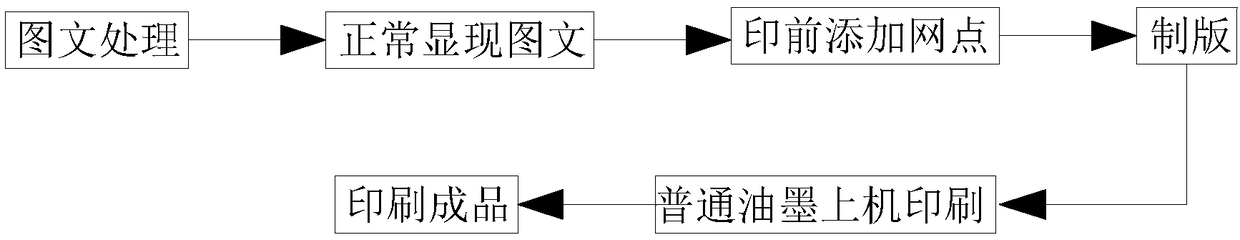

[0030] A special plate-making method for anti-copying, comprising the following steps:

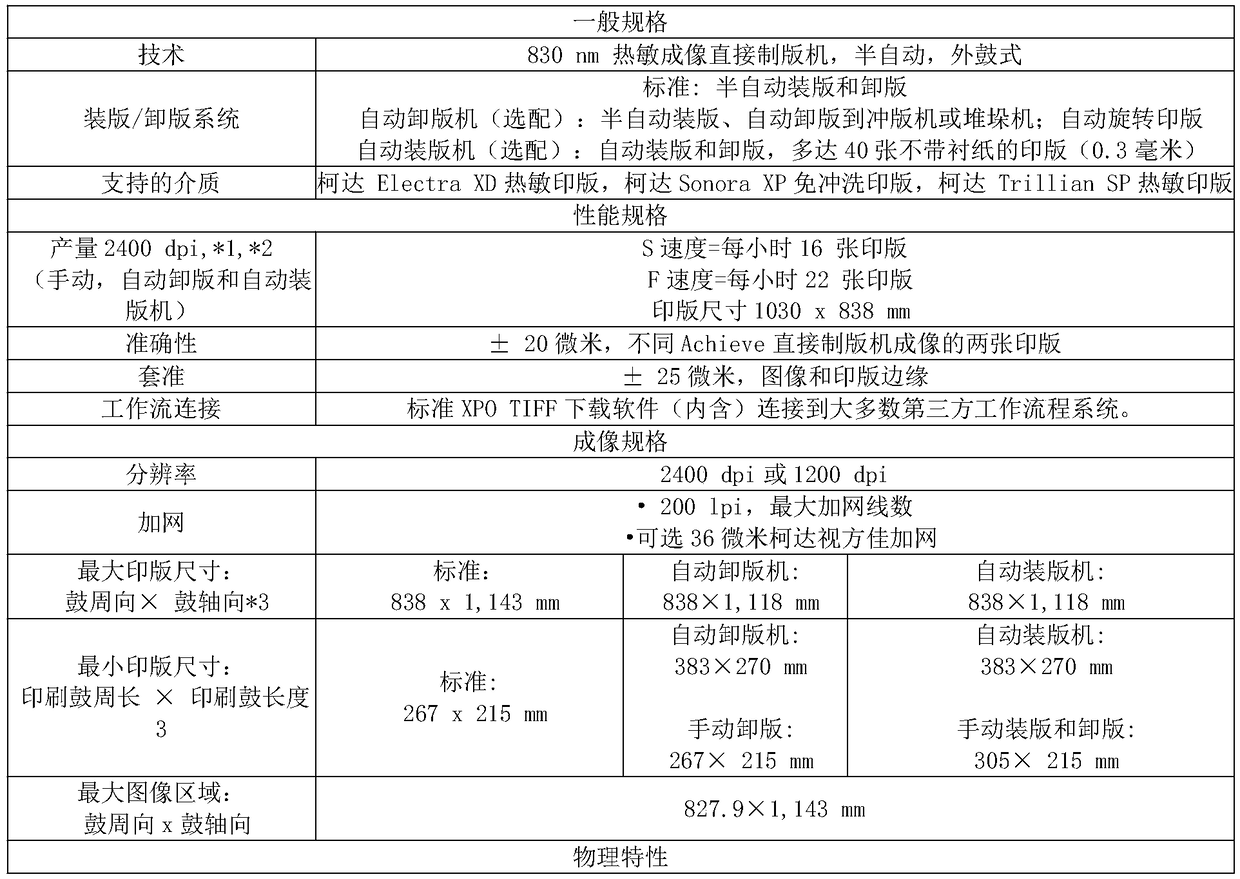

[0031] 1), graphics and text processing: use the design software Adobe Industrator (hereinafter referred to as AI) to make graphics and texts, and carry out pre-press typesetting of the above-mentioned graphics and texts through the AI software, and divide the above-mentioned graphics and texts into normal display graphics and anti-counterfeiting shading; 2), pre-press network cable adjustment: open the normal display graphics and anti-counterfeit shading in the Kodak Prinergy software, and use the Kodak Prinergy software to respectively adjust the normal display graphics and the anti-counterfeit background 3), merging graphics and texts: the normal display graphics and anti-counterfeiting shading patterns through the pre-press screen adjustments of step 2) are merged by the AI software to form a combined graphic and text; 4), plate making: combine The combined graphics and text are ou...

Embodiment 2

[0036] A special plate-making method for anti-copying, comprising the following steps:

[0037] 1), graphics and text processing: make graphics and texts through the design software Photoshop (hereinafter referred to as PS), and carry out pre-press typesetting of the above-mentioned graphics and texts through the PS software, and divide the above-mentioned graphics and texts into normal display graphics and anti-counterfeiting shading; 2 ), pre-press network line adjustment: open the normal display graphics and anti-counterfeit shading in the Kodak Prinergy software, and use the Kodak Prinergy software to respectively adjust the normal display graphics and the anti-counterfeit shading Carry out pre-press network line adjustment; 3), merge graphics and text: the normal appearance graphic and text and anti-counterfeit shading of the pre-press screen line adjustment through step 2) are merged to form combined graphics and text by the PS software; 4), plate-making: combine all Out...

Embodiment 3

[0042] A special plate-making method for anti-copying, comprising the following steps:

[0043] 1), graphics and text processing: use the design software Adobe Industrator (hereinafter referred to as AI) to make graphics and texts, and carry out pre-press typesetting of the above-mentioned graphics and texts through the AI software, and divide the above-mentioned graphics and texts into normal display graphics and anti-counterfeiting shading; 2), pre-press network cable adjustment: open the normal display graphics and anti-counterfeit shading in the Kodak Prinergy software, and use the Kodak Prinergy software to respectively adjust the normal display graphics and the anti-counterfeit background 3), merging graphics and texts: the normal display graphics and anti-counterfeiting shading patterns through the pre-press screen adjustments of step 2) are merged by the AI software to form a combined graphic and text; 4), plate making: combine The combined graphics and text are ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com