Milk feeding device capable of separating calves from cows in cattle farm

A technology for dairy farms and energy use, applied in animal feeding devices, applications, animal husbandry, etc., can solve the problems of milk waste, troublesome and laborious, and achieve the effect of large milk capacity and preventing cows from rushing to eat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

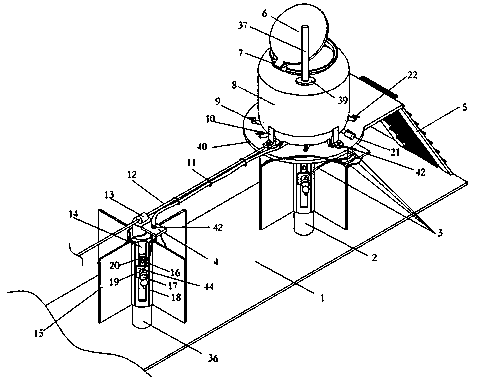

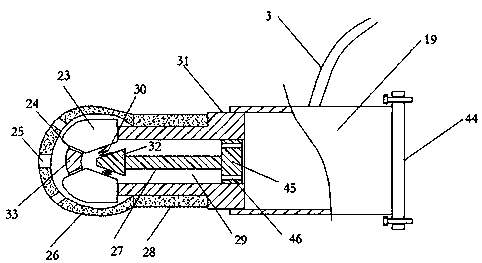

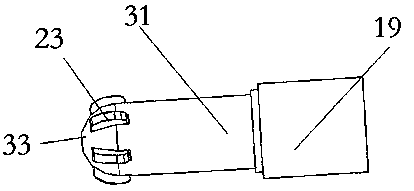

[0027] refer to Figure 1-6 , a milking device capable of separating calves for a dairy farm, comprising a base 1, a main support 2, several auxiliary supports 36 and a milk bucket 8, the main support 2 and the auxiliary supports 36 are all fixed on the base 1, and the main support 2 There is a carrying plate 40 installed on the top, and the milk bucket 8 is installed on the carrying plate 40. During the actual operation, the volume of the cow is relatively large, so the heights of the main pillar 2 and several auxiliary pillars 36 are higher than the height of the cow. Escalator 5 can be installed on the edge of carrying plate 40, and the two ends of escalating ladd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com