Track spike tightening device with oil spraying maintenance function

A technology of elastic device and road spike, which is applied in the direction of track maintenance, road, track, etc., can solve the problems of poor effect of oil coating and anti-rust maintenance, reduce labor intensity and workload, save material cost, and avoid oil wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

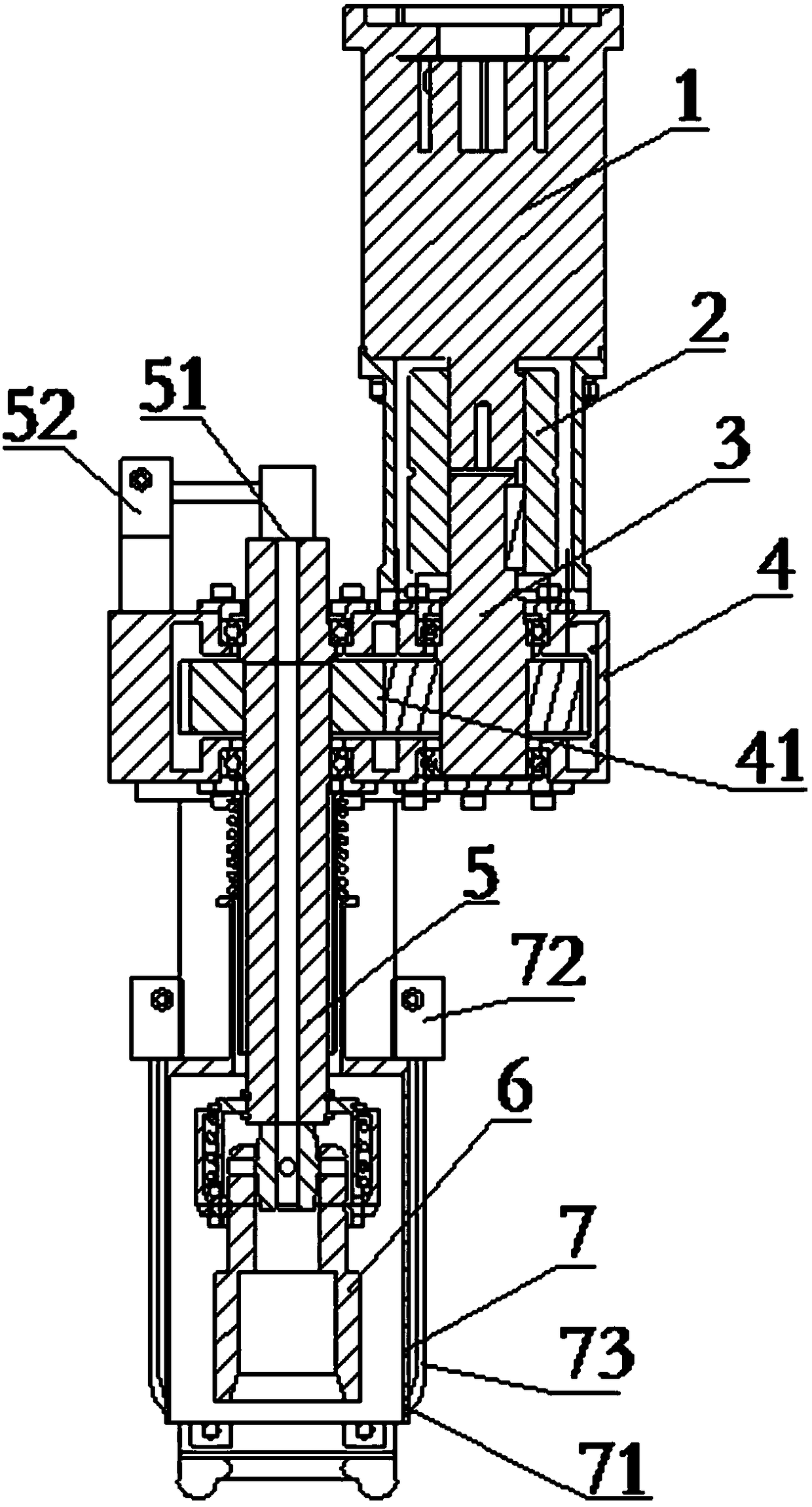

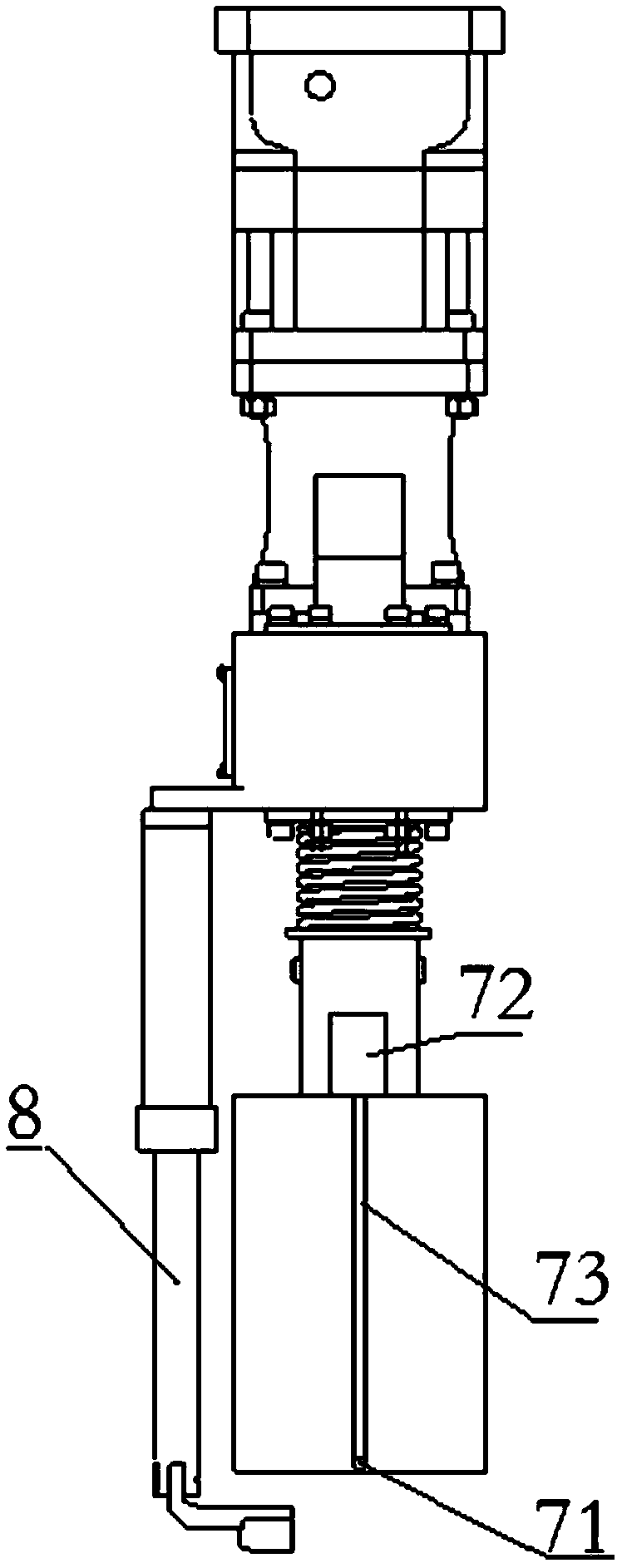

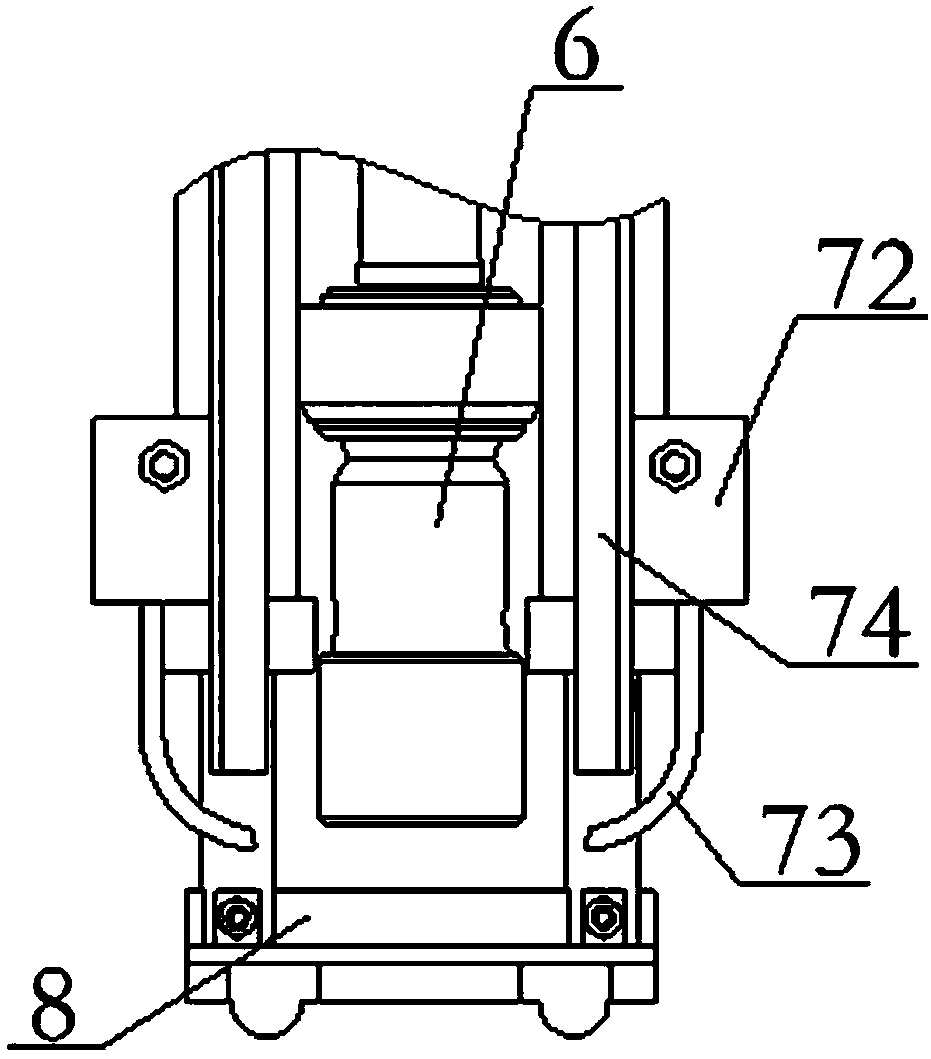

[0024] Combine below Figure 1-5 Describe in detail the technical scheme of the spike tightening device combined with the oil injection maintenance function:

[0025] A road stud tightening device combined with oil injection maintenance function, comprising a wrench main shaft 5, a transmission gear 41 is installed at one end of the wrench main shaft 5, a flexible wrench head 6 is installed at the other end, and a central oil injection hole 51 is opened in the center of the wrench main shaft 5, The flexible wrench head 6 outside is equipped with side spray device 7.

[0026] One end of the central oil injection hole 51 is equipped with a first valve block 52 and is connected with the oil supply pipeline.

[0027] Side spray device 7 can be selected figure 1 , 2 enclosed structure as shown or image 3 , 4 The open structure shown.

[0028] The closed structure is that a side spray sleeve is installed on the outside of the flexible wrench head 6, a second valve block 72 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com