Color film base plate, preparation method thereof, display panel and display device

A color filter substrate and substrate substrate technology, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of complex preparation process, and achieve the effect of simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

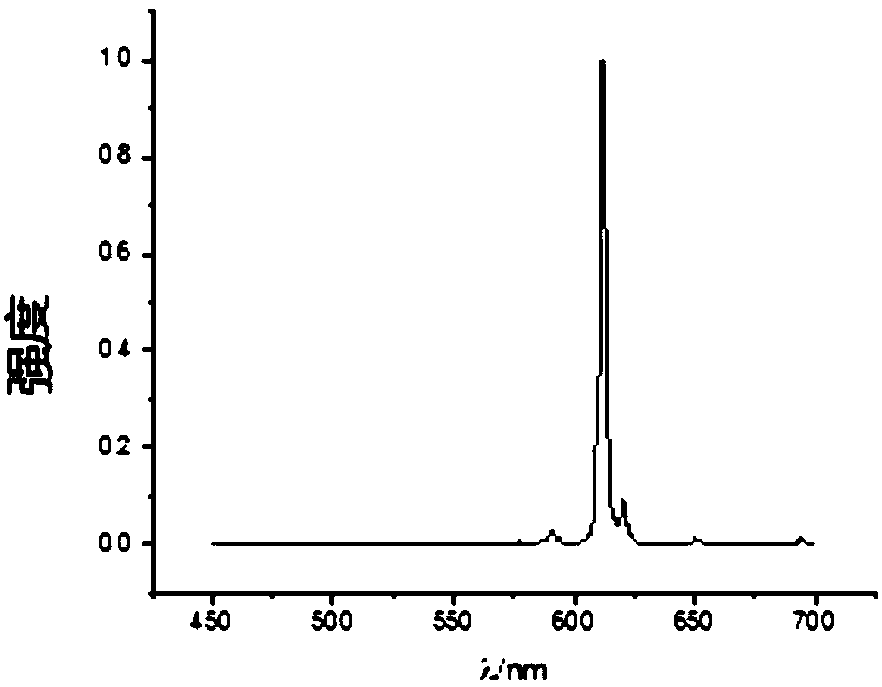

[0041] The preparation method of the europium complex is preferably:

[0042] Ligand and EuCl 3 Reaction in ethanol, the pH value condition is 7-8, and europium complex is obtained.

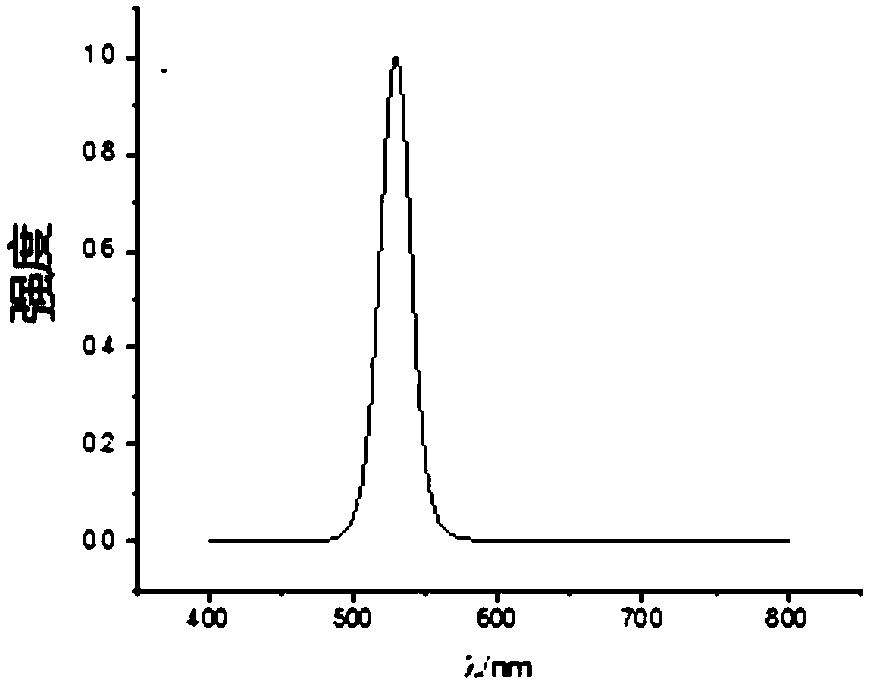

[0043] In the present invention, the green light quantum dots are preferably CdSe / CdS, CdSe / ZnS, LnP or CsPbBr x I 3-x type perovskite quantum dots, where 2≤x≤3.

[0044] The surface of the green light quantum dot is usually connected with a first complex different from the europium complex, and the first complex is oleic acid-oleylamine or alkylphosphine oxide. When the europium complex replaces part or all of the first complex by means of replacement and binds to the green light quantum shell, a quantum dot capable of simultaneously emitting narrow-band red light and green light under blue light excitation is obtained. The green light quantum dot has high energy, which can excite the europium complex to emit red light better.

[0045] Preferably, the ratio of the amount of the europium com...

Embodiment 1

[0069] 1) Preparation of europium complexes

[0070] The ligand shown in formula (II), with 1 / 3 equivalent of EuCl 3 ·6H 2 O was refluxed in ethanol, a small amount of NaOH was added to adjust the pH to about 8, and the europium complex represented by formula (V) was obtained by centrifugal separation.

[0071] 2) Replacement of rare earth ligands

[0072] Dissolve the CdSe / CdS quantum dots with oleic acid-oleylamine complex on the surface in the methanol-chloroform system to make a solution of about 10 mg / mL, slowly add the europium complex represented by formula (V) to a concentration of 5 mg / mL Methanol solution with continuous stirring, and finally get quantum dots replaced by rare earth complex ligands, such as Figure 5 shown.

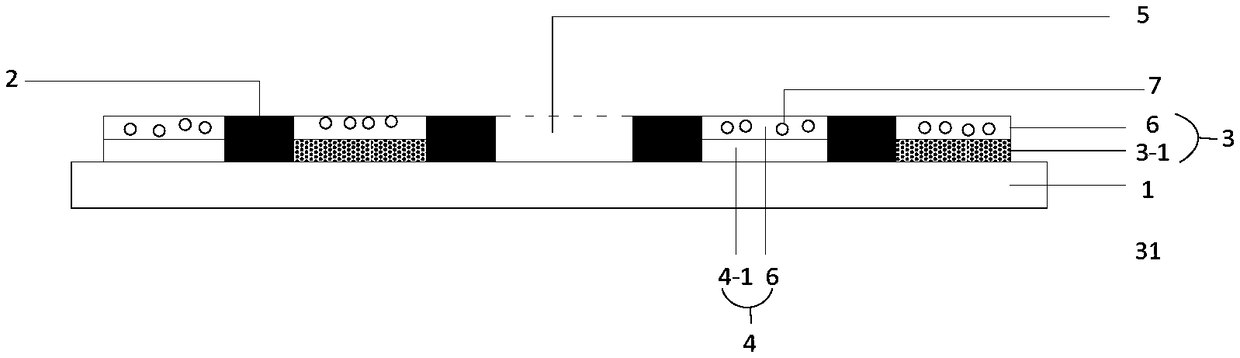

[0073] 3) Preparation of color filter substrate

[0074] A black matrix is formed on a transparent glass substrate through a patterning process, the black matrix defines a plurality of pixel areas, and the plurality of pixel areas include ...

Embodiment 2

[0081] 1) Preparation of europium complexes

[0082] The ligand shown in formula (II), with 1 / 3 equivalent of EuCl 3 ·6H 2 O was refluxed in ethanol, a small amount of NaOH was added to adjust the pH to about 8, and the europium complex represented by formula (V) was obtained by centrifugal separation.

[0083] 2) Replacement of rare earth ligands

[0084] Dissolve the CdSe / CdS quantum dots with oleic acid-oleylamine complex on the surface in the methanol-chloroform system to make a solution of about 10 mg / mL, slowly add the europium complex represented by formula (V) to a concentration of 5 mg / mL Methanol solution with continuous stirring, and finally get quantum dots replaced by rare earth complex ligands, such as Figure 5 shown.

[0085] 3) Preparation of color filter substrate

[0086] A black matrix is formed on a transparent glass substrate through a patterning process, the black matrix defines a plurality of pixel areas, and the plurality of pixel areas include ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap