Film pressing machine for sampling head

A sampling head and laminator technology, which can be used in hand-held tools, manufacturing tools, etc., can solve the problems of low work efficiency, high labor intensity and high rejection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments,

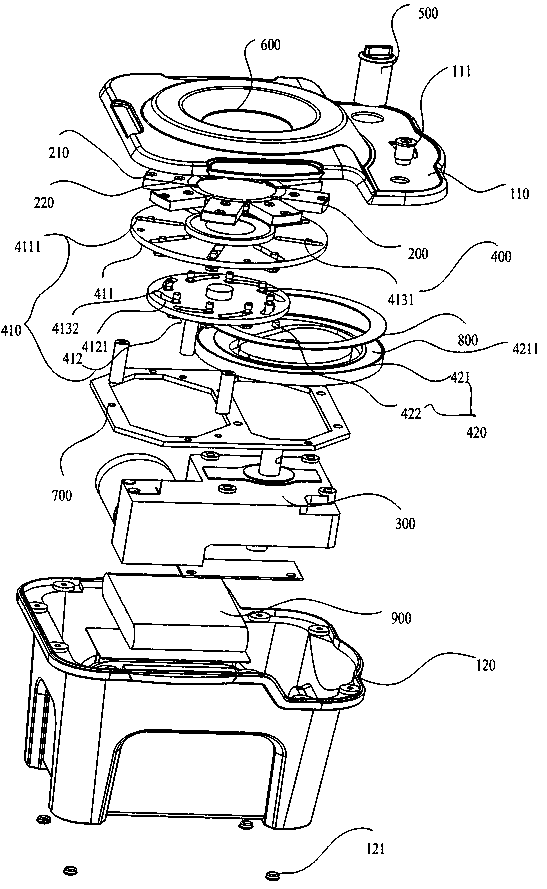

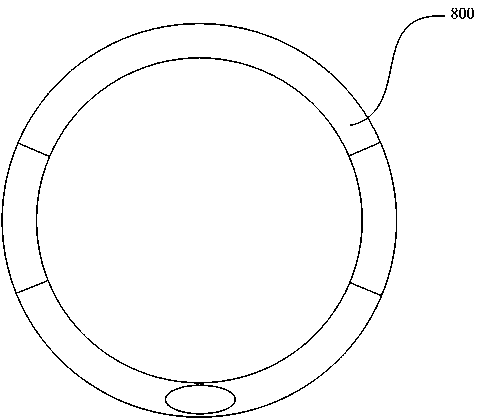

[0026] The present invention proposes a film laminating machine for a sampling head, referring to Figure 1-Figure 3 As shown, it includes a casing 100 and a lamination mechanism arranged in the casing 100, the lamination mechanism includes a lamination tooth 200, a driving member 300, a transmission assembly 400, a switch 500 and a controller,

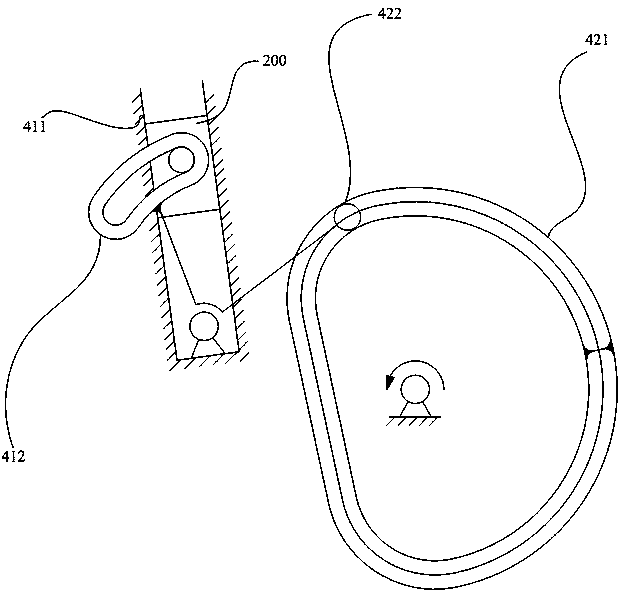

[0027] The transmission assembly 400 is respectively connected with the driving member 300 and the film-pressing tooth 200, and is used to convert the rotation of the driving member 300 into the reciprocating intermittent linear motion of the film-pressing tooth 200 along the radial direction of the sampling head;

[0028] The controller is connected in communication with the drive member 300 and the switch 500 respectively. Preferably, the switch is a switch with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com