Dyeing machine retractable cloth placing device and dyeing machine

A dyeing machine, telescopic technology, applied in the direction of liquid/gas/steam jet propelling fabrics, etc., can solve the problems of easy to turn the cloth or reverse the cloth, high local accumulation of the fabric, affecting the running state of the fabric in the cloth storage tank, etc., to avoid The effect of inverting or turning the cloth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings. It is only stated here that the words for directions such as up, down, left, right, front, back, inside, and outside that appear or will appear in the text of the present invention are only based on the accompanying drawings of the present invention, and are not specific to the present invention. limited.

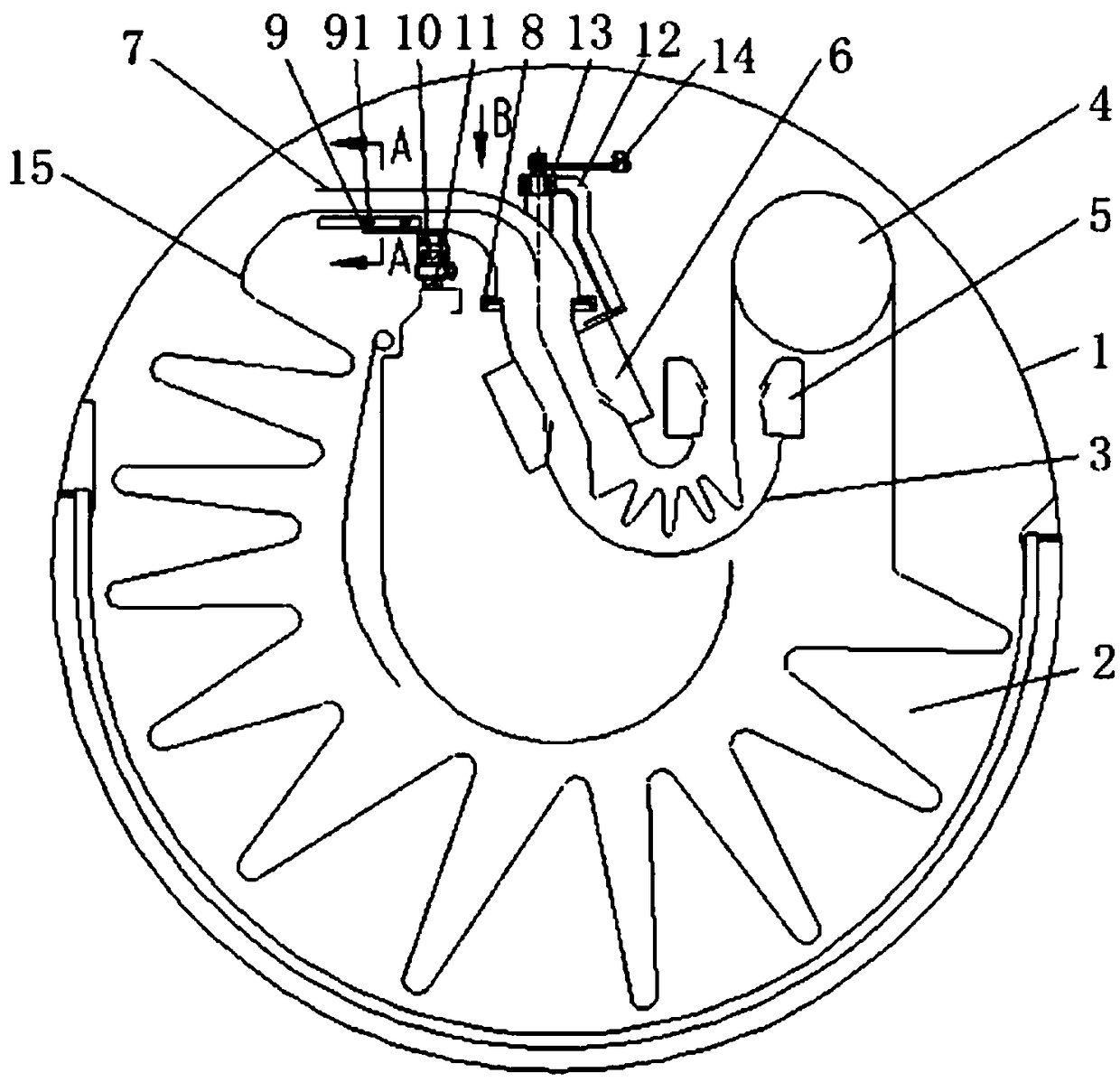

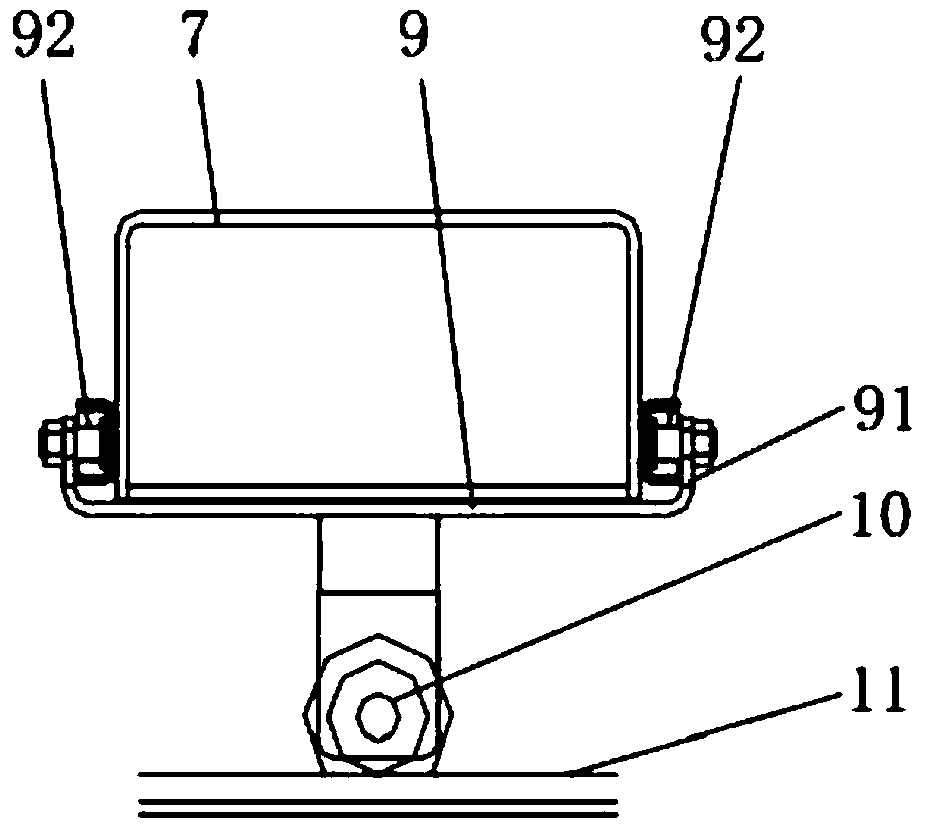

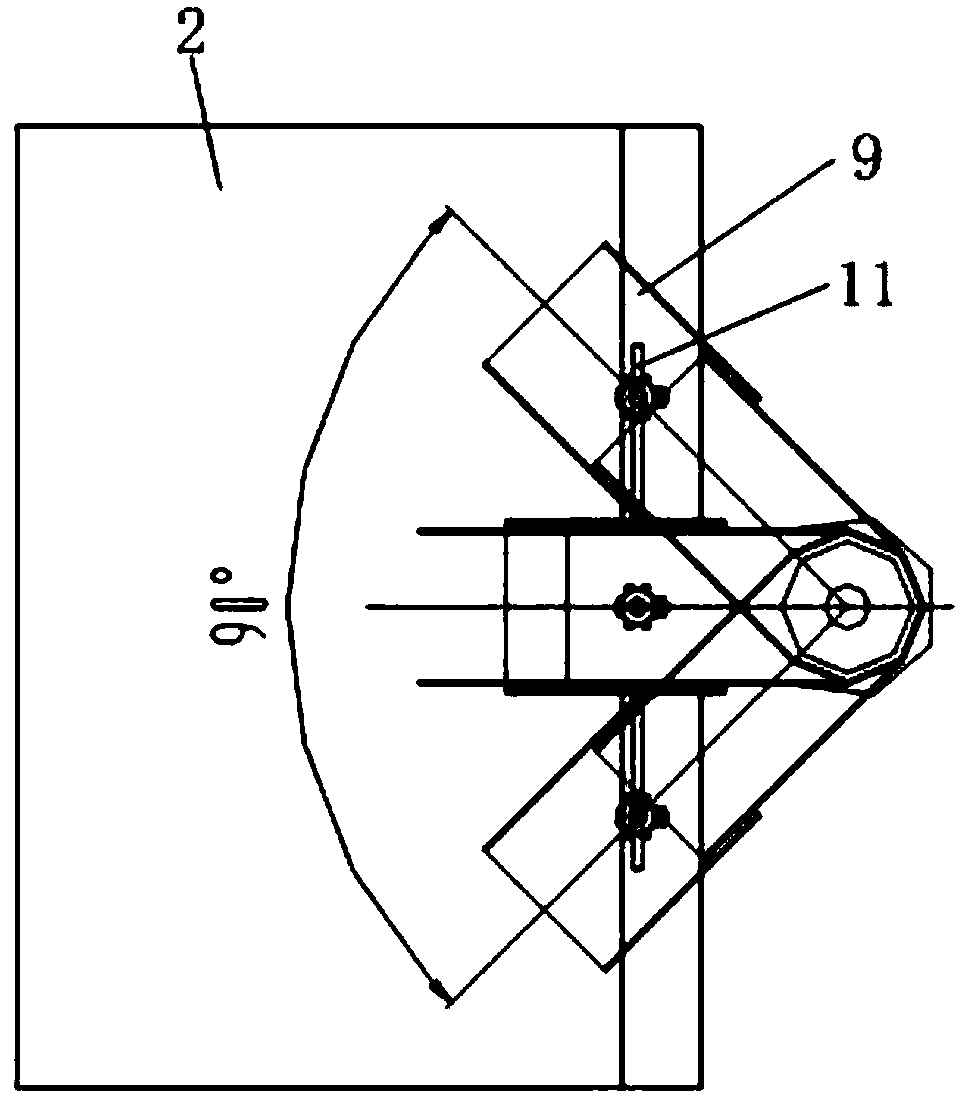

[0020] by figure 2 The angle of view shown is the orientation reference of this article, combined with figure 1 and image 3 Give details. A specific embodiment of the present invention provides a dyeing machine, comprising a main cylinder 1, a cloth storage tank 2, a U-shaped cloth guide pipe 3, a cloth lifting roller 4, a front nozzle 5 and a rear nozzle 6, wherein the cloth storage tank 2, The U-shaped cloth guiding pipe 3, the cloth lifting roller 4, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com