Anti-slip board collecting device for construction site

A construction site and anti-skid plate technology, which is applied to buildings, roads, special pavements, etc., can solve the problems of small anti-skid plates, inconvenient movement of large machinery, and inability to collect anti-skid plates efficiently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

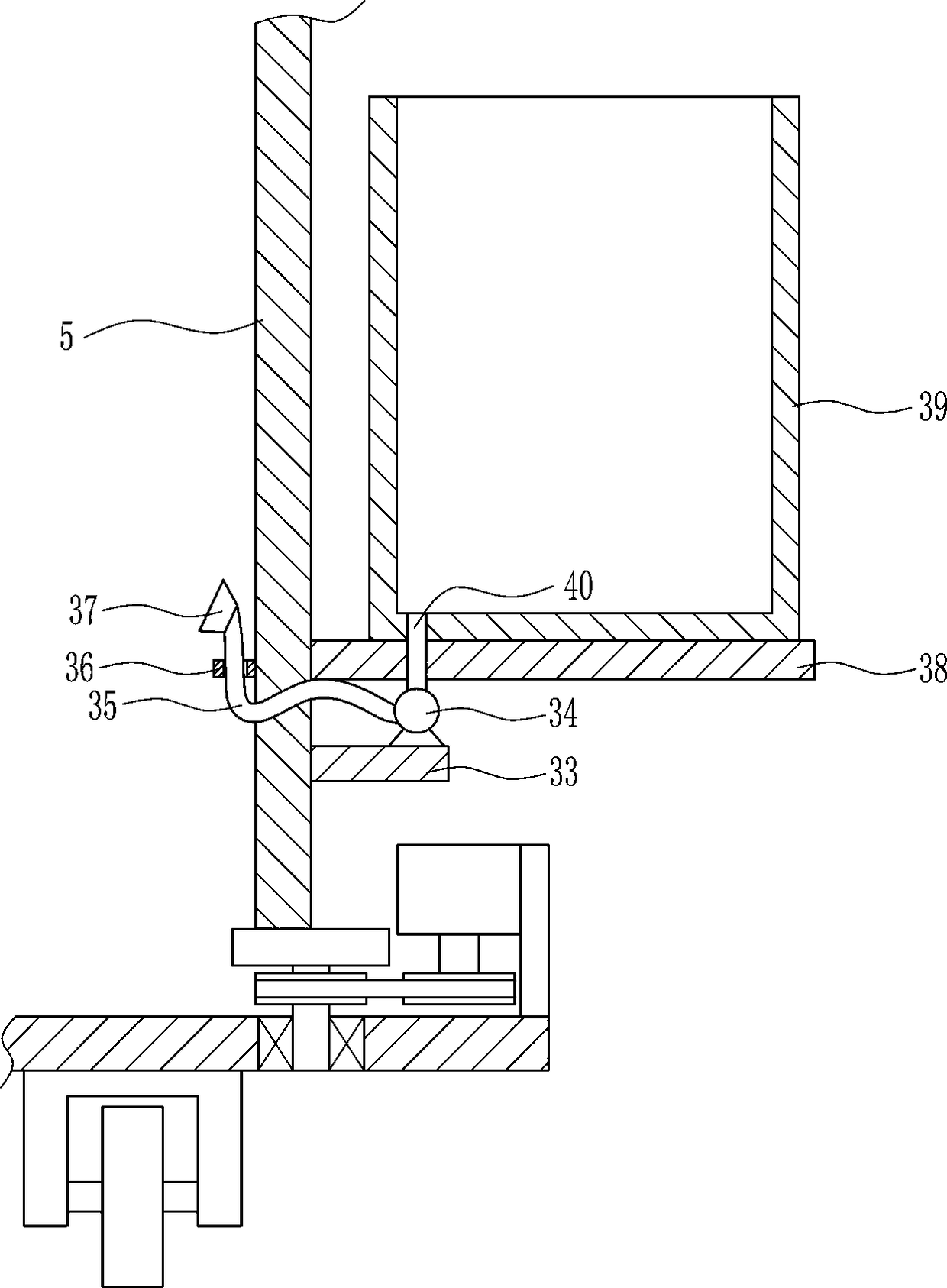

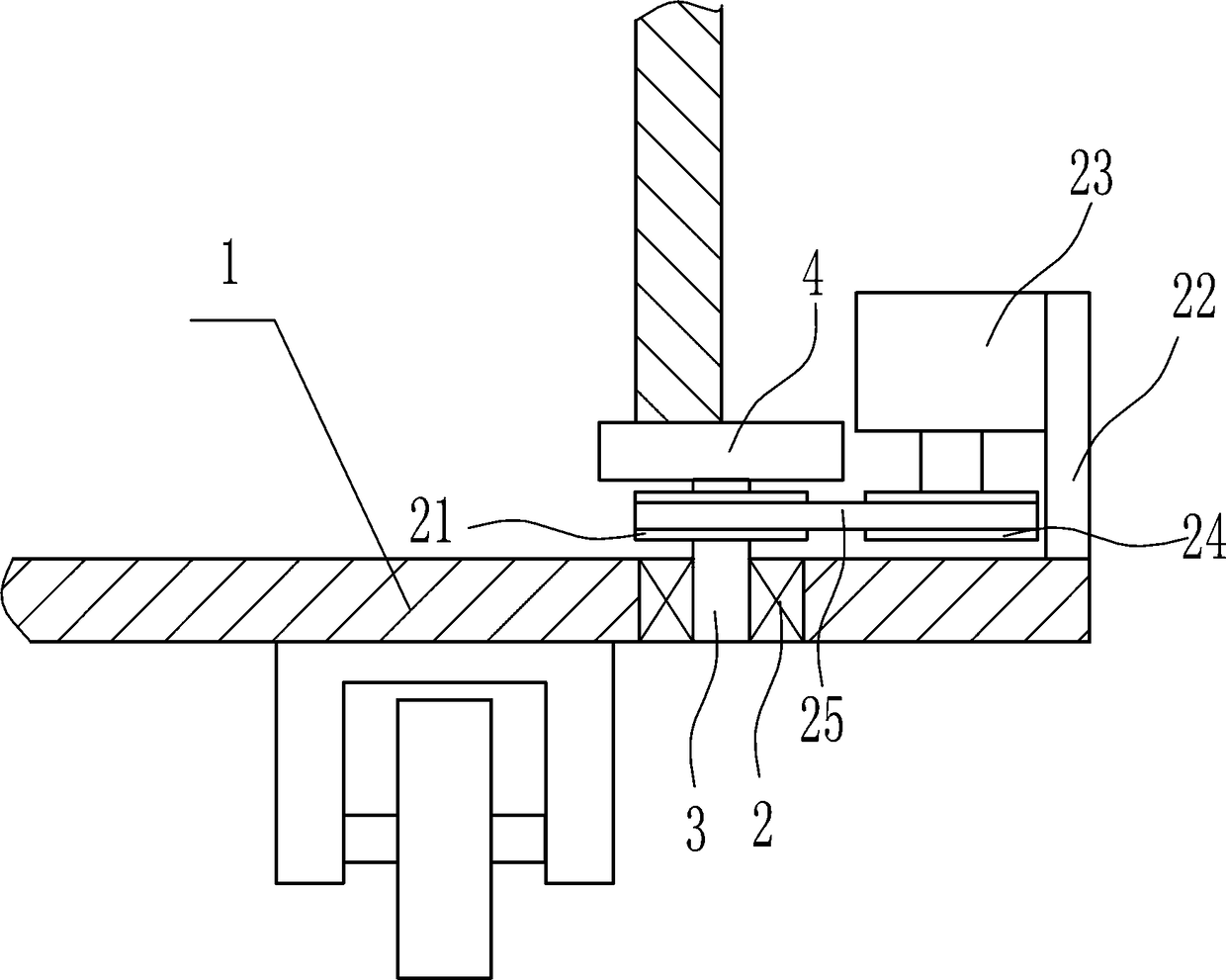

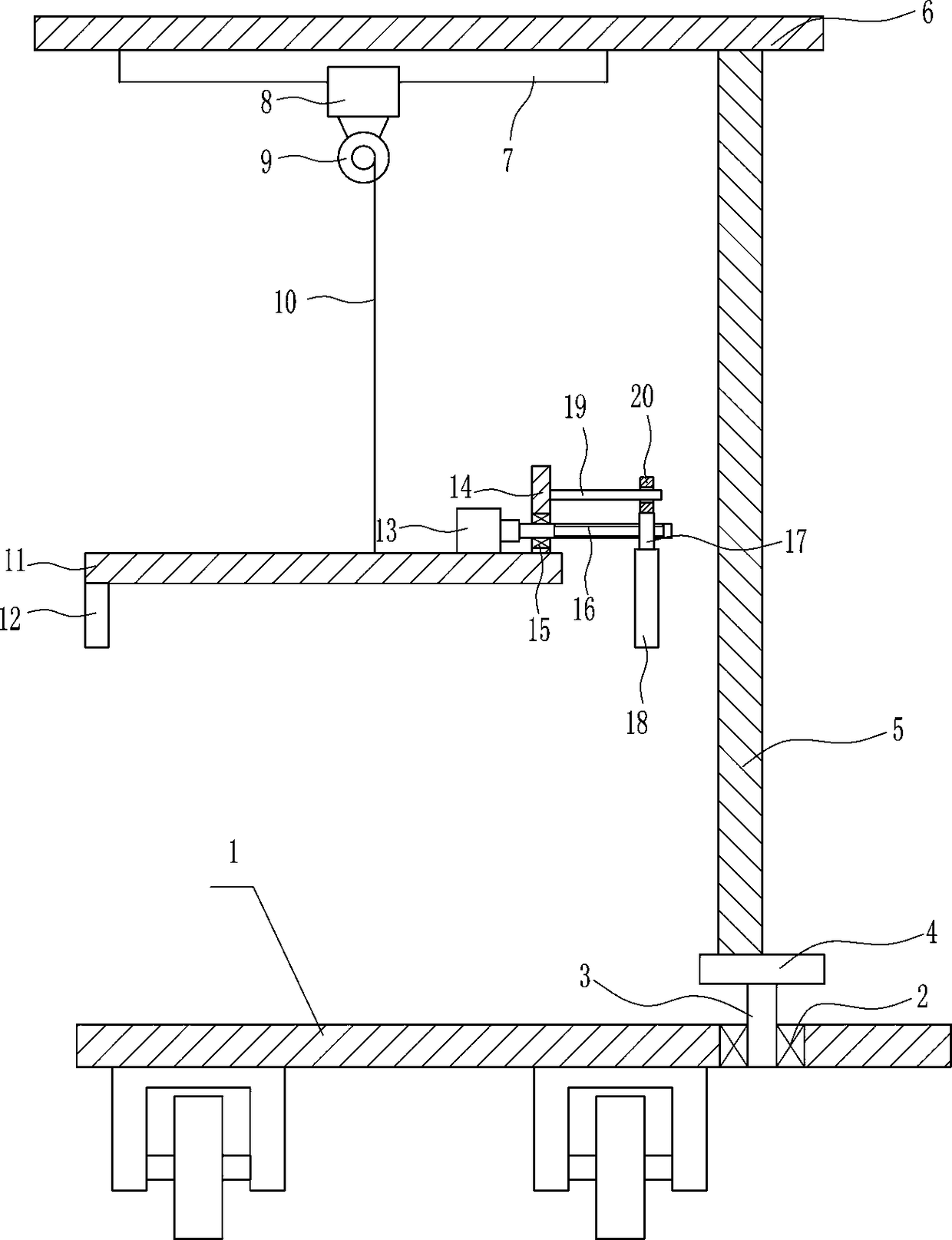

[0023] A kind of anti-skid plate collecting equipment for construction site, such as Figure 1-5As shown, it includes a vehicle frame 1, a first bearing 2, a rotating shaft 3, a first turntable 4, a first bracket 5, a second bracket 6, a slide rail 7, a slider 8, a first reel 9, and a first rope 10. The third bracket 11, the first fixed block 12, the first motor 13, the fourth bracket 14, the second bearing 15, the first screw rod 16, the first nut 17, the second fixed block 18, the sliding rod 19 and the sliding sleeve 20. A first bearing 2 is embedded in the right part of the frame 1, and a rotating shaft 3 is interference-connected in the first bearing 2, and a first turntable 4 is connected above the rotating shaft 3, and a first bracket 5 is above the first turntable 4 , a second bracket 6 is connected to the top of the first bracket 5, a slide rail 7 is fixedly connected to the bottom of the second bracket 6, a slider 8 is slidably connected to the middle of the slide ra...

Embodiment 2

[0025] A kind of anti-skid plate collecting equipment for construction site, such as Figure 1-5 As shown, it includes a vehicle frame 1, a first bearing 2, a rotating shaft 3, a first turntable 4, a first bracket 5, a second bracket 6, a slide rail 7, a slider 8, a first reel 9, and a first rope 10. The third bracket 11, the first fixed block 12, the first motor 13, the fourth bracket 14, the second bearing 15, the first screw rod 16, the first nut 17, the second fixed block 18, the sliding rod 19 and the sliding sleeve 20. A first bearing 2 is embedded in the right part of the frame 1, and a rotating shaft 3 is interference-connected in the first bearing 2, and a first turntable 4 is connected above the rotating shaft 3, and a first bracket 5 is above the first turntable 4 , a second bracket 6 is connected to the top of the first bracket 5, a slide rail 7 is fixedly connected to the bottom of the second bracket 6, a slider 8 is slidably connected to the middle of the slide r...

Embodiment 3

[0028] A kind of anti-skid plate collecting equipment for construction site, such as Figure 1-5 As shown, it includes a vehicle frame 1, a first bearing 2, a rotating shaft 3, a first turntable 4, a first bracket 5, a second bracket 6, a slide rail 7, a slider 8, a first reel 9, and a first rope 10. The third bracket 11, the first fixed block 12, the first motor 13, the fourth bracket 14, the second bearing 15, the first screw rod 16, the first nut 17, the second fixed block 18, the sliding rod 19 and the sliding sleeve 20. A first bearing 2 is embedded in the right part of the frame 1, and a rotating shaft 3 is interference-connected in the first bearing 2, and a first turntable 4 is connected above the rotating shaft 3, and a first bracket 5 is above the first turntable 4 , a second bracket 6 is connected to the top of the first bracket 5, a slide rail 7 is fixedly connected to the bottom of the second bracket 6, a slider 8 is slidably connected to the middle of the slide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com