Combustible gas monitoring data abnormal cause judgment method and device

A technology for abnormal data and gas monitoring, applied in the field of detection, can solve problems such as unchecked data, achieve monitoring effects and improve the accuracy of early warning, and eliminate inaccurate monitoring data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

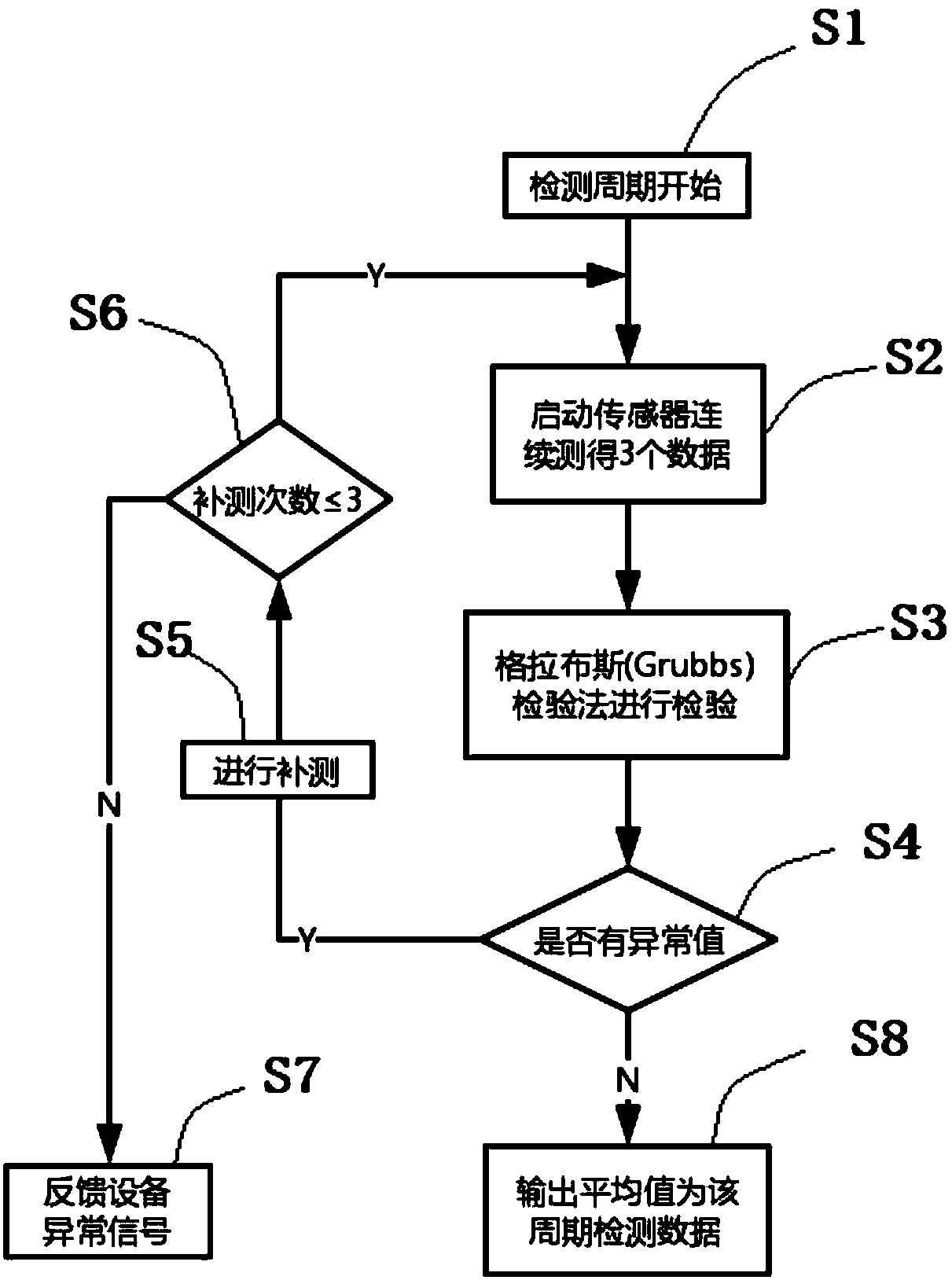

[0056] The method for judging the abnormal cause of combustible gas monitoring data in the present invention includes:

[0057] Step S1, the detection cycle starts;

[0058] Step S2, starting the sensor to continuously measure a set of data;

[0059] Step S3, inspecting each set of data collected by the combustible gas detector;

[0060] Step S4, judge whether each set of data contains abnormal data, if it is detected that the set of data contains abnormal data, discard the set of data, and enter step S5, if there is no abnormal data in the set of data, it is confirmed as the periodic detection value, enter step S8;

[0061] Step S5, start supplementary detection, and enter step S6;

[0062] Step S6, judging whether the number of supplementary detections is within the set number of times N, if yes, return to step S2, start the sensor to detect a new group of arrays; if there is no qualified data within the number of times N, then enter step S7, where N is based on The actu...

Embodiment 2

[0096] The difference between this embodiment and the above-mentioned embodiment is that in the step S3, the Raida criterion is used to test the n data of continuous detection, and the Raida criterion is based on the standard deviation of three times the measurement series as the limit selection standard, which Given a confidence probability of 99.73%, this criterion is applicable to situations where the number of measurements n>10 or the standard error σ has been calculated through a large number of repeated measurements in advance. Xi is an equal-precision measurement value subject to a normal distribution, and their arithmetic mean X, residual vi and standard deviation σ can be obtained first. If |Xi-X|>3σ, the suspicious value Xi contains gross errors and should be discarded; if |Xi-X|≤3σ, the suspicious value Xi is a normal value and should be retained. After discarding the suspicious value, recalculate the average value and standard deviation of other measured values e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com