Novel robot control system

A control system and robot technology, applied in the field of robots, can solve the problems of affecting the service life, difficult to adjust the length of cables, easy to be contaminated with dust, etc., and achieve the effect of being easy to use when powered on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

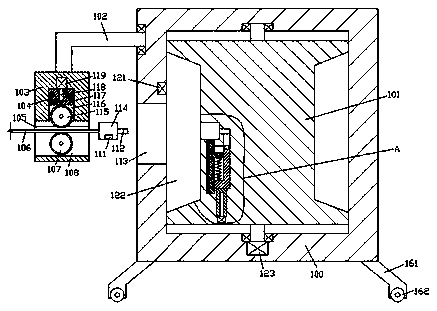

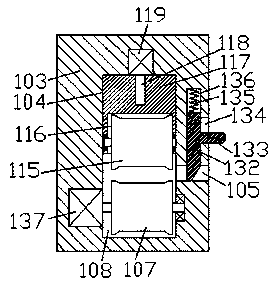

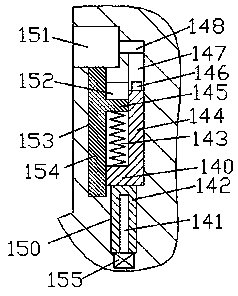

[0016] Combine below Figure 1-3 The present invention will be described in detail.

[0017] refer to Figure 1-3 , according to an embodiment of the present invention, a new type of robot control system includes a base 100 and an end head 114 used in cooperation with the base 100. The left end face of the base 100 is provided with an opening 113, and the The inner wall on the right side of the opening cavity 113 is connected with a rotating cavity 122 , and a winding frame 101 is installed in the rotating cavity 122 rotatably. A connecting rod 102 is rotatably installed on the left end face of the base 100 , a fixing block 103 is fixed at the bottom end of the connecting rod 102 , and a wire passage cavity 105 runs through the front end face of the fixing block 103 from left to right. A first sliding cavity 136 extends up and down the inner top wall of the cavity 105 . A baffle 132 is installed in the first sliding cavity 136 in a sliding fit, and the top of the baffle 132 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com