Seamless edge-closing processing method

A processing method and seamless technology, applied in the field of garment processing, can solve the problems that the sewing thread does not have elastic deformation ability, affects the elastic deformation range of the edge, and the trajectory of the sewing thread affects the appearance, so as to improve the cutting efficiency and eliminate the sewing thread trajectory, avoiding aesthetic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

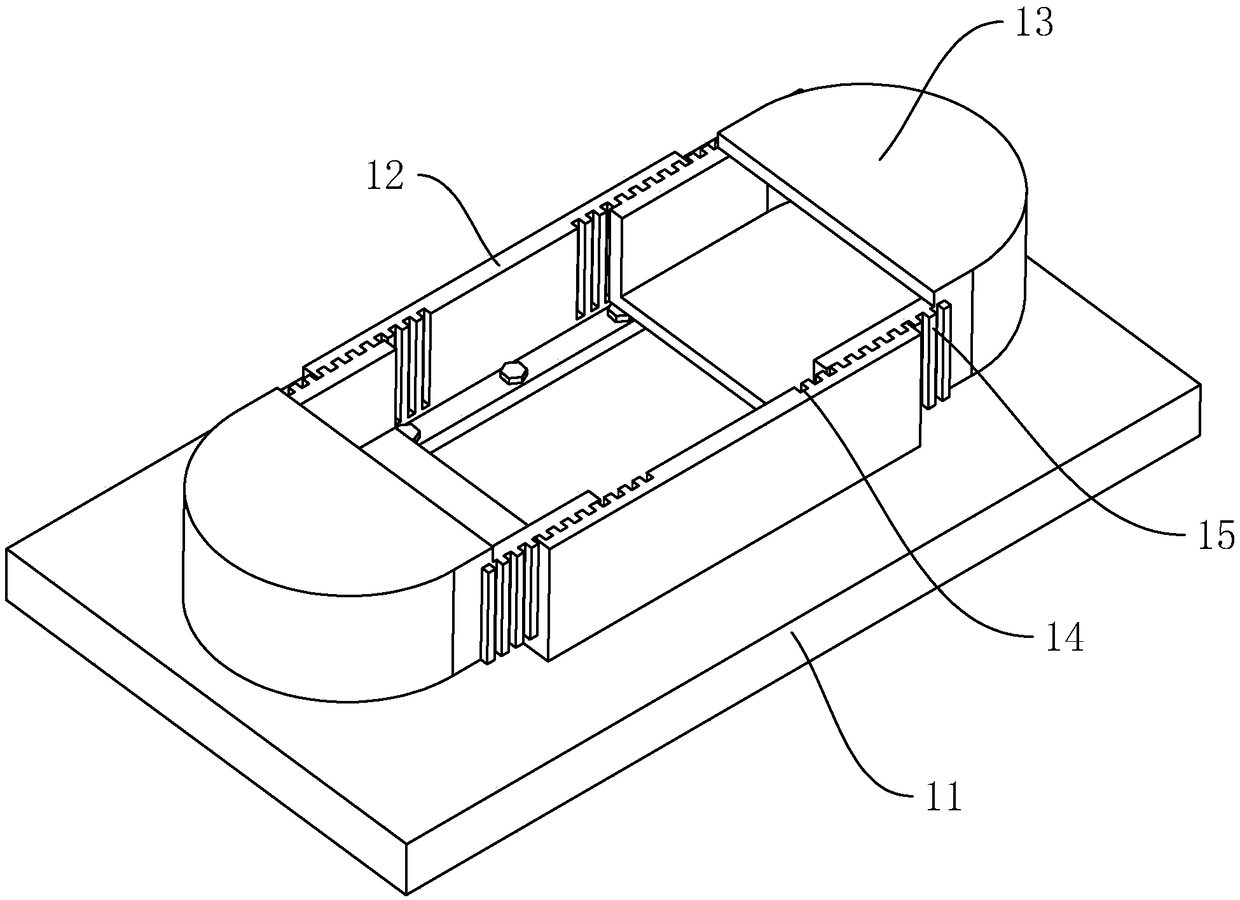

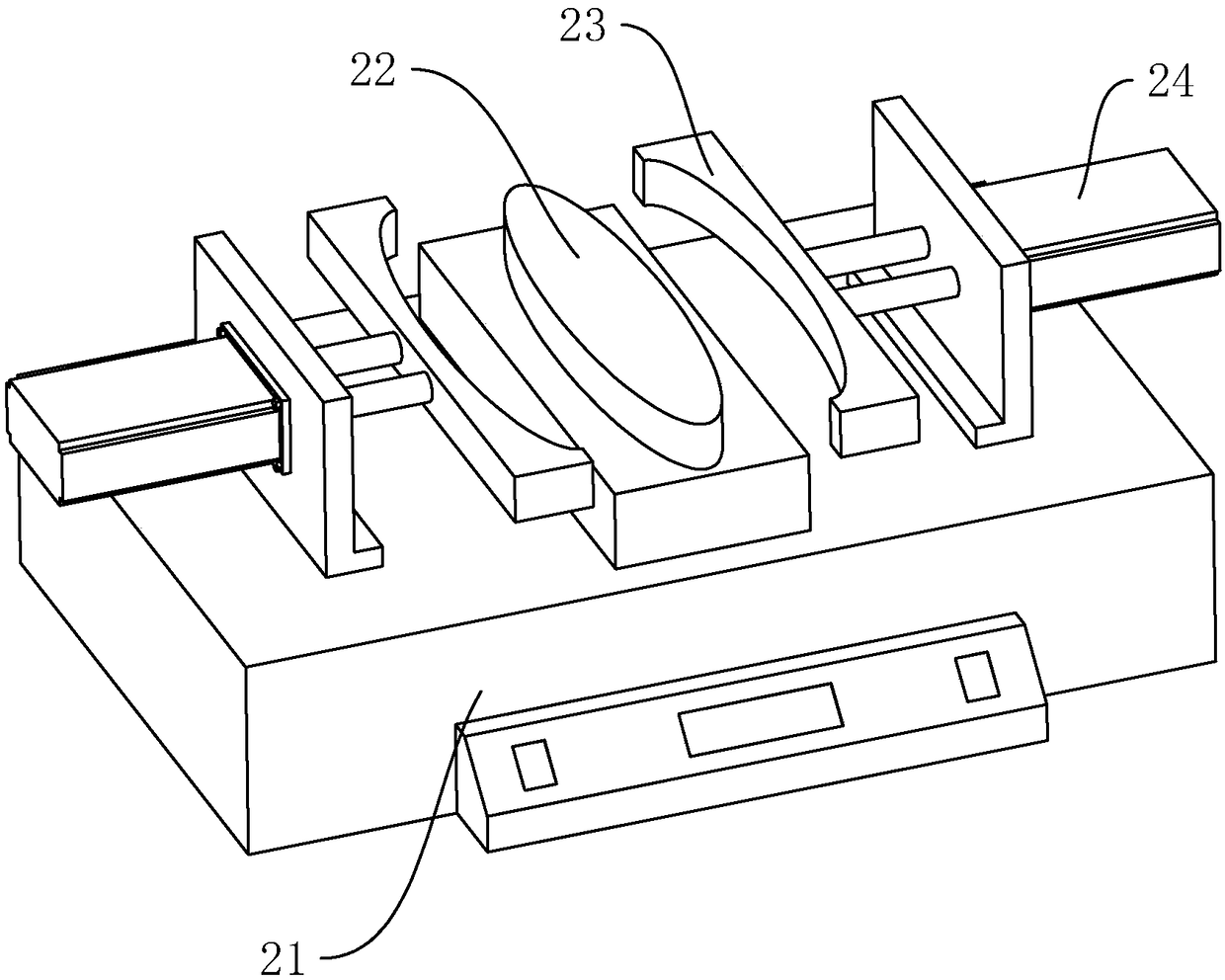

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0038] The seamless edge finishing processing method comprises the steps of:

[0039] A. Cutting hot melt adhesive:

[0040] 1. Raw material: TPU hot melt adhesive film;

[0041] 2. Equipment: laser cutting machine;

[0042] 3. Working process: Set the cutting parameters of the laser cutting machine according to the length and width of the edge, set the roll-shaped TPU hot-melt adhesive film on the feeding end of the laser cutting machine, and run the laser cutting machine normally, and finally complete the collection Cut TPU hot melt adhesive film;

[0043] 4. Beneficial effects: TPU hot melt adhesive film has three advantages of good flexibility, strong adhesion fastness and water washing resistance. It is an excellent fabric adhesive material, so it is selected as the adhesive material for elastic and clothing ;At the same time, by using a laser cuttin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com