Fuselage lateral and heading load combined application device and load application method

An application device and combined loading technology, applied in the direction of aircraft component testing, etc., can solve the problems of increased coordination and control difficulty, test protection, less loading points, etc., and achieve the effect of facilitating structural damage detection, reasonable distribution of loading points, and uniform load distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the purpose, technical solutions and advantages of the implementation of this application clearer, the technical solutions in the embodiments of the application will be described in more detail below in conjunction with the drawings in the embodiments of the application.

[0038] In order to apply the load for the ground strength test of the full-scale aircraft structure, it can not only meet the needs of various load applications in the test, but not increase the sticking nodes on the surface of the aircraft too much; it can accurately apply the lateral / heading load required in the test , Without causing the structure to bear unwanted side load components, this application provides a device and method for applying a combined lateral and heading load of the fuselage.

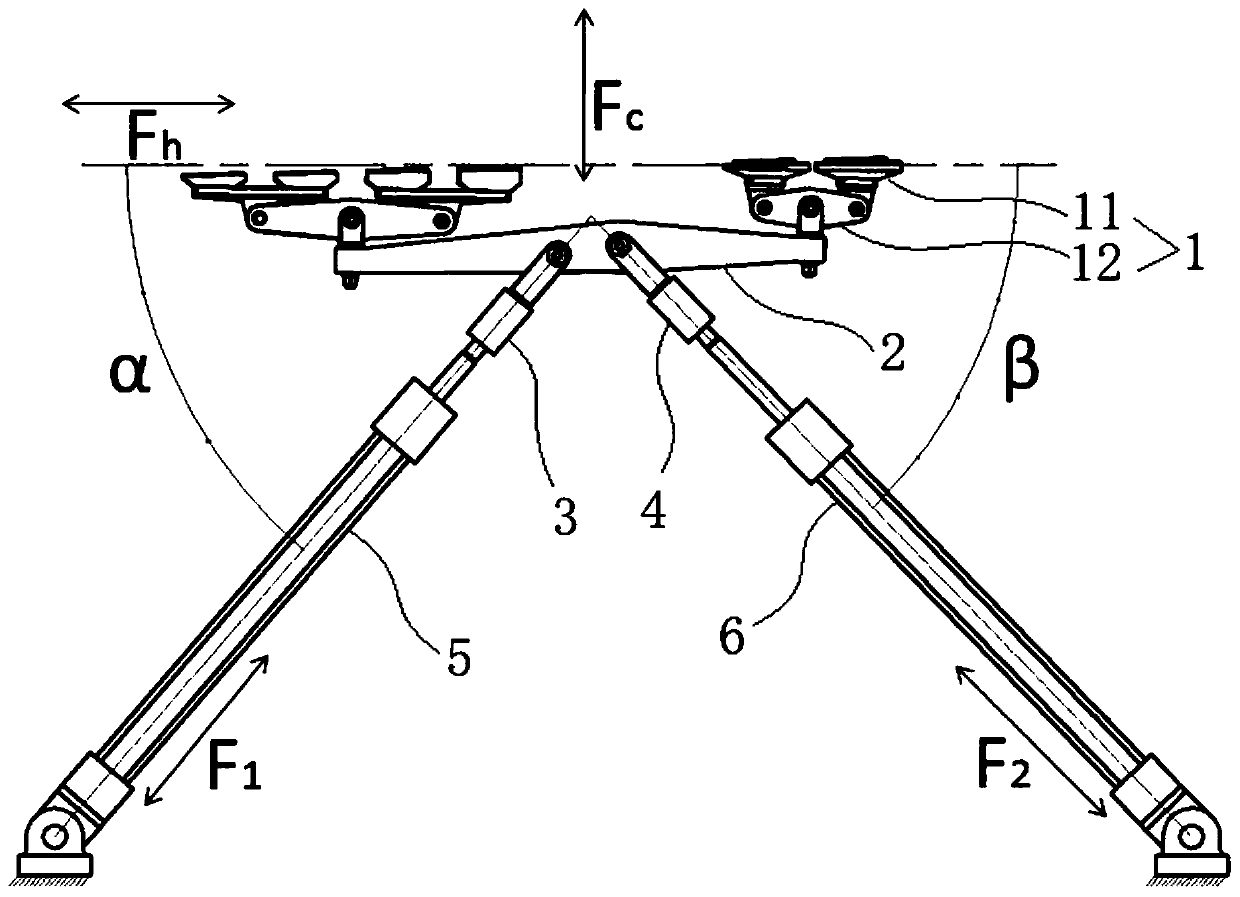

[0039] Such as figure 1 As shown, this application first provides an application device for the combined loading of fuselage lateral and heading loads. The application device mainly includes: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com