Soft tent

A technology of software and tarpaulin, applied in the field of soft tents, to achieve the effect of simple and quick implementation and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

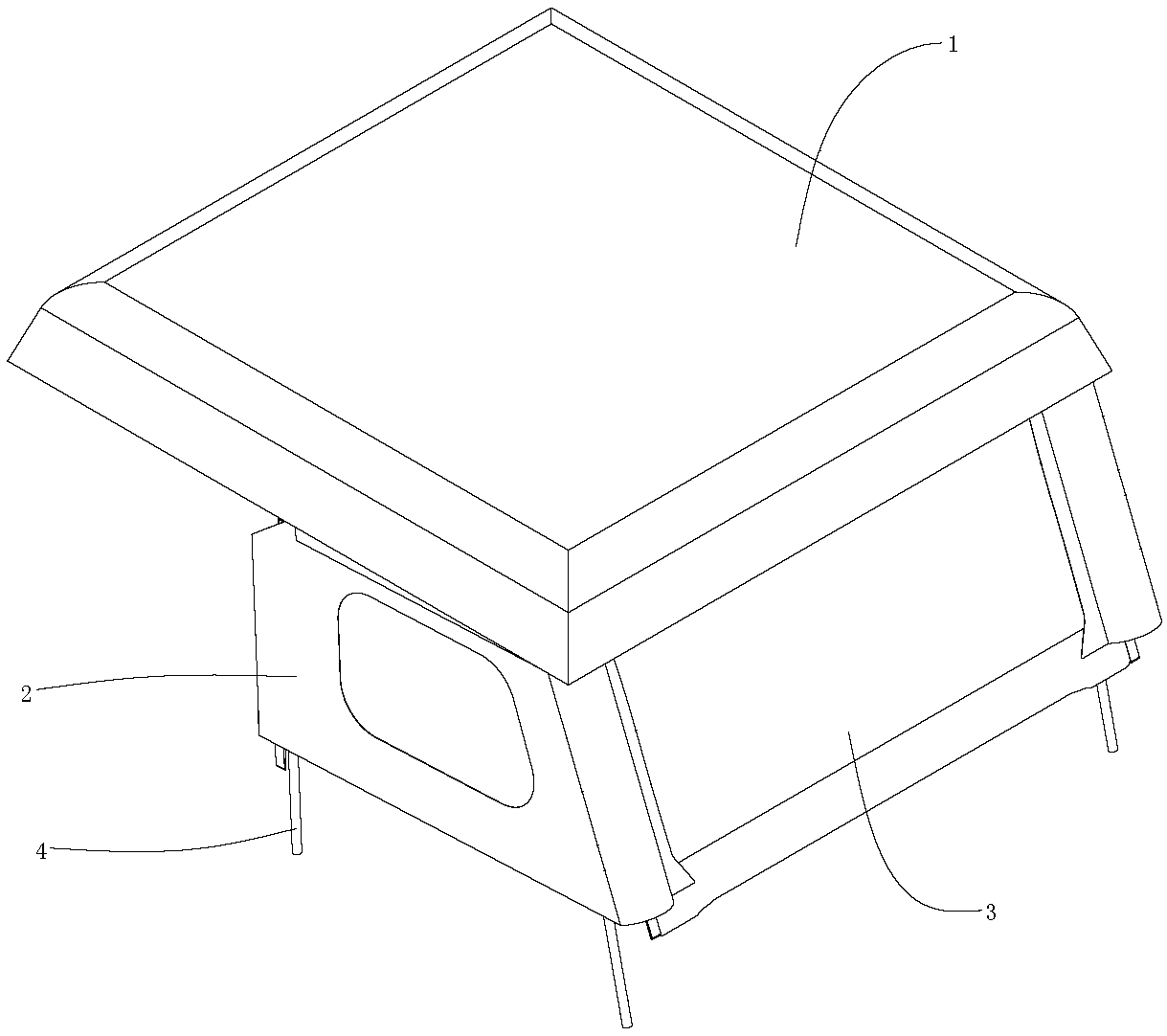

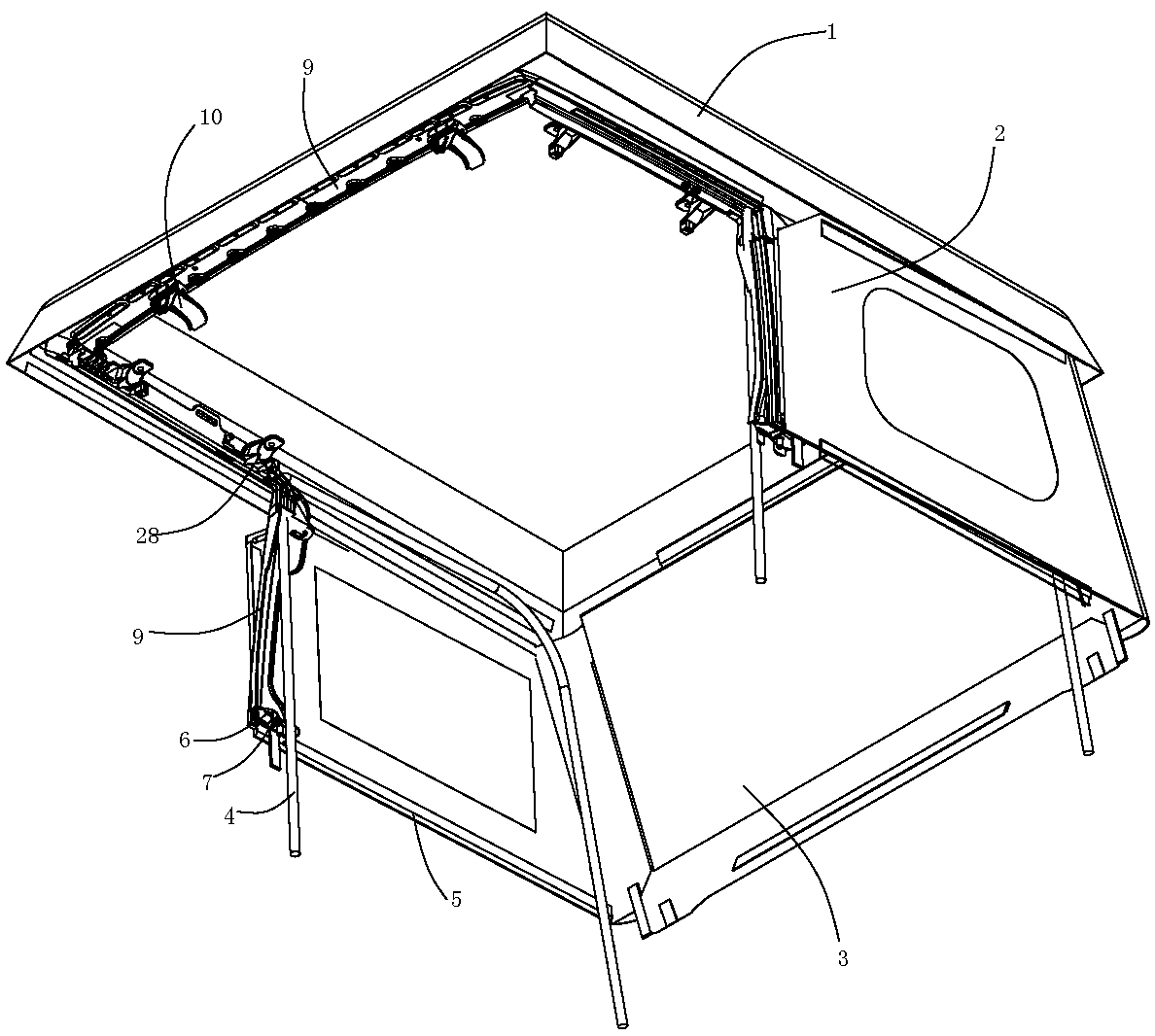

[0024] Embodiment: a soft top for a convertible, comprising:

[0025] The supporting frame 9 located on both sides, the lower end of the supporting frame 9 is provided with a fixing part 6 for fixing to the vehicle body, the front side of the supporting frame 9 is provided with a side gap 30 for connecting the side tarpaulin 2, the supporting frame 9 The upper end is provided with a fixed platform 15;

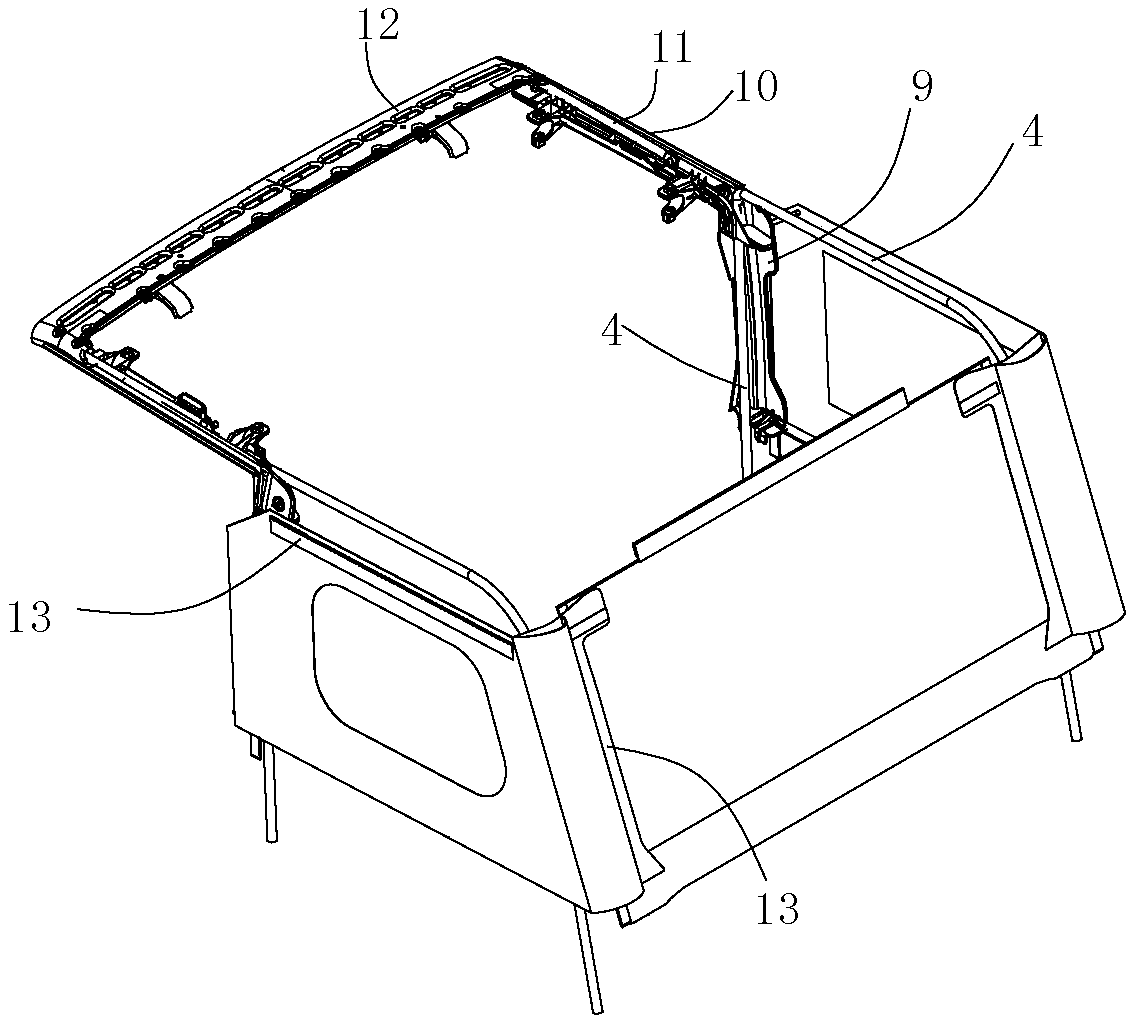

[0026] Two horizontal support frames 10 are respectively connected above the support frames 9 on both sides; the horizontal support frame 10 includes a fixed plate 20 connected to the fixed platform 15, and the outer side of the fixed plate 20 is provided with a side connecting plate 8, and the An L-shaped plate is connected to the outer side of the side connecting plate 8, and an upper gap 22 for fixing the roof cloth is formed between the L-shaped plate and the side connecting plate 8;

[0027] The rotating support frame includes a connecting plate 12 located in the middle, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com