Fault detection method and system

A fault detection and distribution network technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of unreliable products, user influence, and high cost, so as to reduce the probability of early failure and improve product reliability. , the effect of saving secondary costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

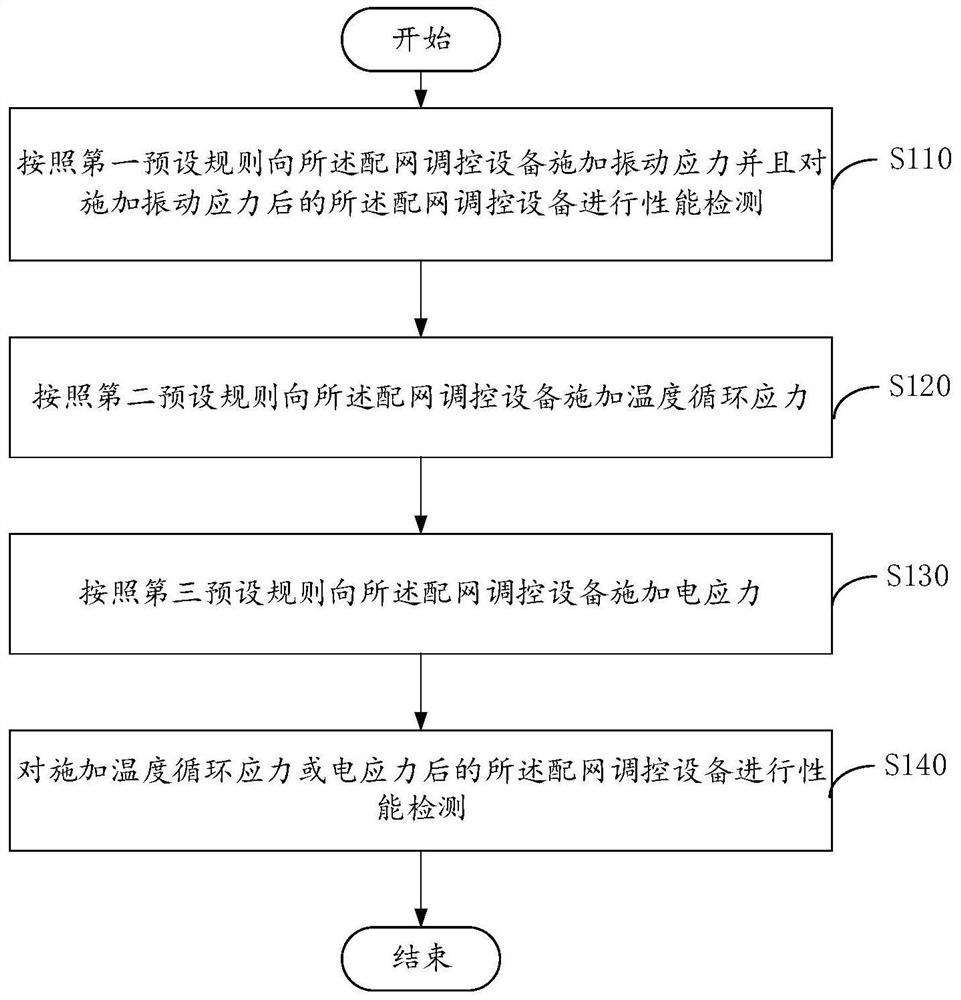

[0047] An embodiment of the present invention provides a fault detection method for detecting early faults of the distribution network control device 10 . Such as figure 1 As shown, the fault detection method includes the following steps.

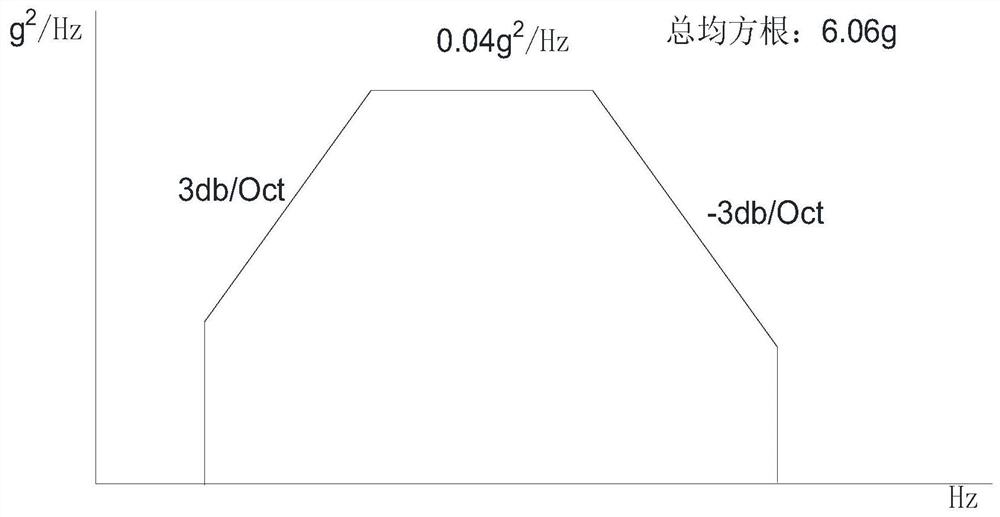

[0048]Step S110, applying the vibration stress to the distribution network regulation device 10 according to a first preset rule, and performing a performance test on the distribution network regulation device 10 after the vibration stress is applied.

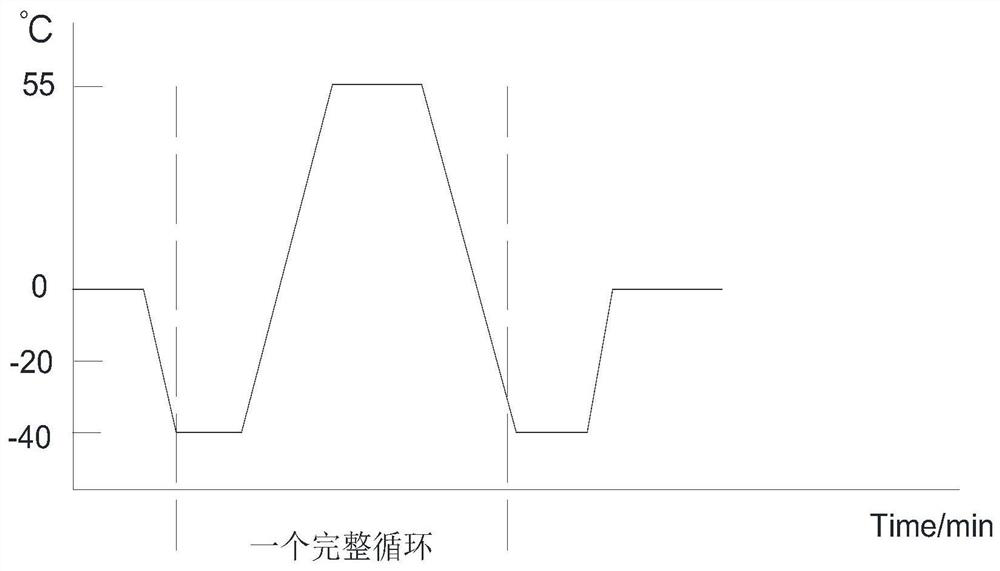

[0049] Step S120, applying temperature cycle stress to the distribution network regulating device 10 according to a second preset rule.

[0050] Step S130, applying electrical stress to the distribution network regulating device 10 according to a third preset rule.

[0051] Step S140, performing a performance test on the distribution network control device 10 after the temperature cycle stress or the electrical stress is applied.

[0052] Wherein, if the detection result of any one perfor...

no. 2 example

[0104] Please refer to Figure 5 , Figure 5 The structural block diagram of the fault detection system provided by the embodiment of the present invention. The embodiment of the present invention also provides a fault detection system for performing each step in the above fault detection method. The fault detection system includes: a vibration stress application device 100 , a temperature stress application device 200 and an electrical stress application device 300 .

[0105] The vibration stress applying device 100 is used for applying vibration stress to the distribution network regulation equipment 10 . In this embodiment, the vibration stress applying device 100 can be used to perform figure 1 For the shown step S110, for the specific implementation of the vibration stress applying device 100, reference may be made to the related description of step S110.

[0106] The temperature stress applying device 200 is used for applying temperature cycle stress to the distributi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com