Carrier tape for electronic components

A technology of electronic components and carrying, applied in the direction of electrical components, electrical components, packaging, etc., can solve the problems of unfavorable installation efficiency of electronic components, unable to increase the speed of tearing and peeling cover tapes, etc., to prevent pollution and bending, and have good installation and operation capabilities , The effect of preventing misidentification and misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

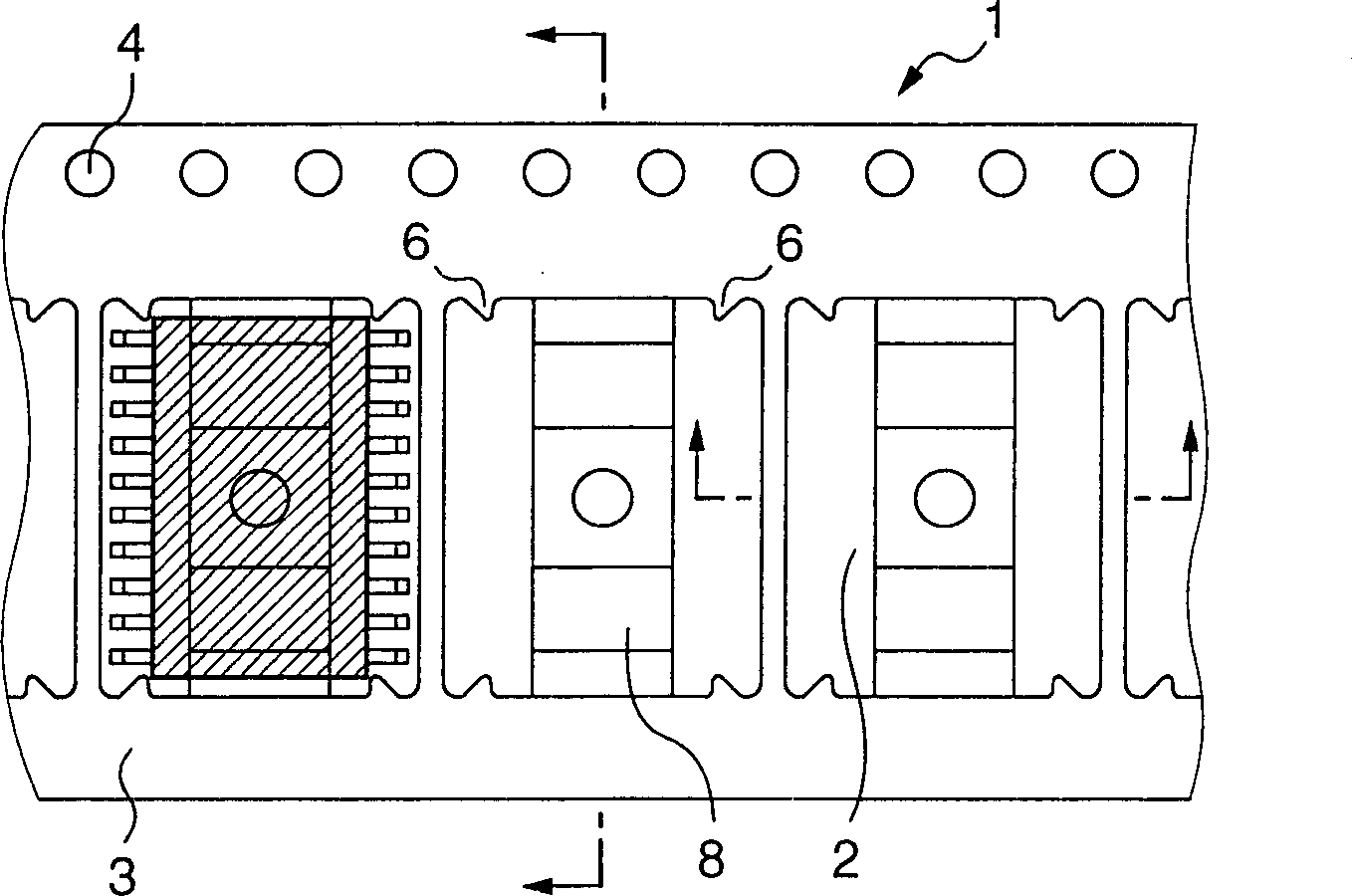

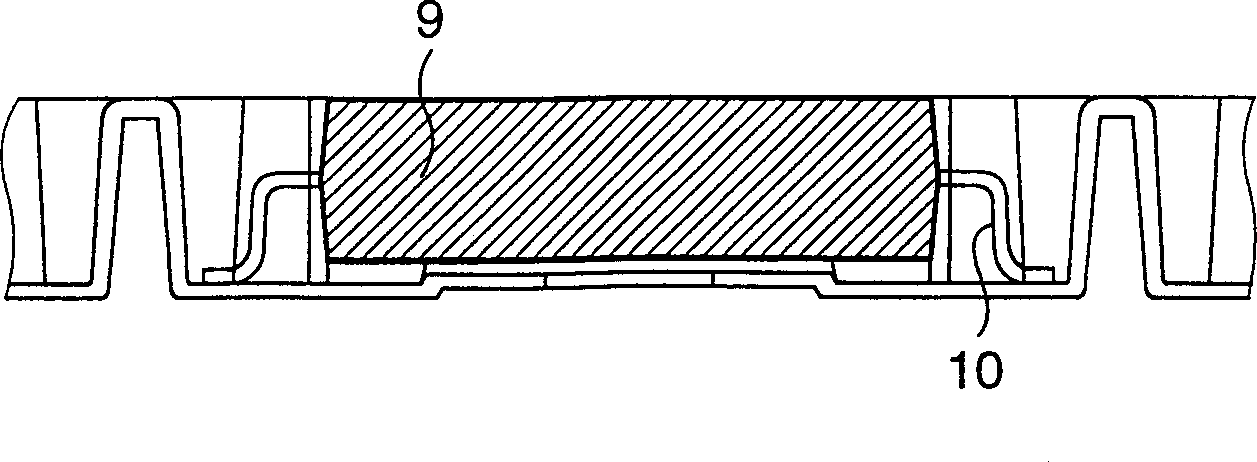

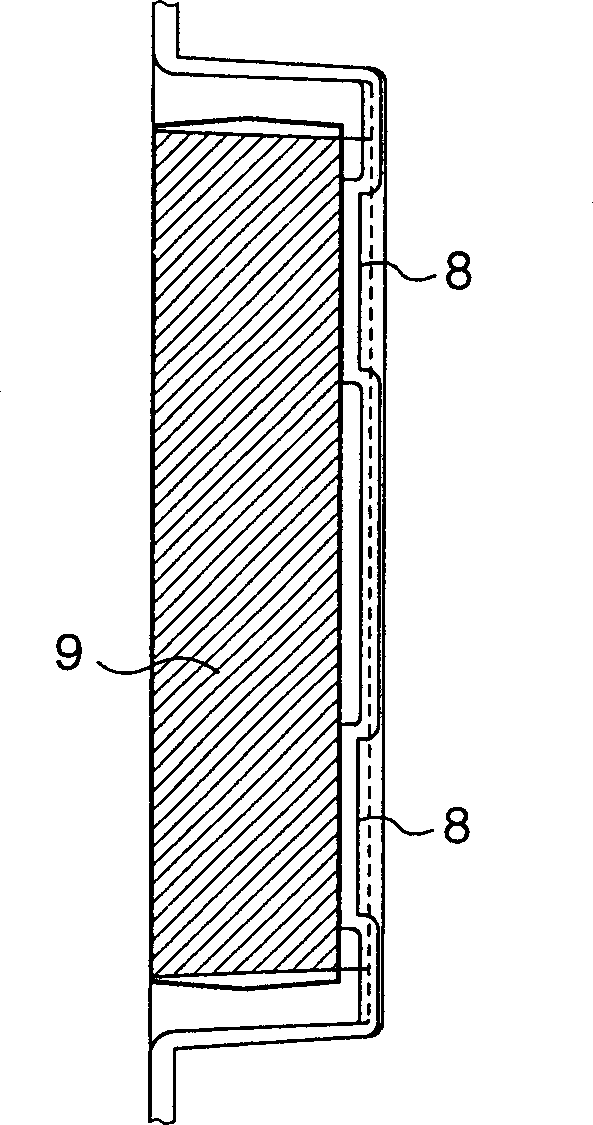

[0033] Figure 1-3 Shown is a carrier tape 1 in which a convex portion 2 is formed so that a plurality of IC packages such as SOP (Small Outline Package), SSOP (Shrink Small Outline Package), TSOP (Thin Small Outline Package), TSSOP (Thin Shrink Small Outline Package) Plug-in) and PLCC (Plastic Lead Sealed Chip Carrier) are stored in it. In the carrier belt 1, two protruding portions A: 6 are formed on the first side wall and the third side wall of the lower convex portion 2 in the longitudinal direction of the belt, in the middle of each side wall of the lower convex portion 2, Whereas two central protrusions 8 are formed on the bottom of the convex portion 2 in a direction perpendicular to the longitudinal direction of the belt.

[0034] Such as Figure 4As shown, the distance A-A between a pair of protruding parts A: 6 is preferably 0.05-0.5mm larger than the length of the electronic component in the longitudinal direction of the tape, measured at the position where the d...

example 2

[0041] The carrier tape in this example is the same as in Example 1, except that Figure 5-7 As shown, two protruding parts B: 7 are formed between protruding parts A: 6, and protruding parts A: 6 are arranged on the first and third side walls of the lower convex part 2, which are all in the longitudinal direction of the belt Located in the middle of some side walls of the lower convex part 2. The protruding portions B: 7 do not protrude beyond the protruding portions A: 6 in a direction perpendicular to the longitudinal direction of the carrier tape, and these protruding portions B: 7 are formed so as to prevent the main body end face of the electronic component 9 from vibrating in its longitudinal direction .

[0042] Preferably, the shortest distance (B) between the two protruding portions B: 7 in the direction perpendicular to the longitudinal direction of the carrier tape is 0.1-1 mm larger than the length (E) of the electronic component in the direction perpendicular to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com