A self-adaptive adjustment device for tig welding torch height

A technology of self-adaptive adjustment and welding torch height, applied in welding equipment, electrode support devices, devices supporting electrode clamps, etc. quality stability and other issues, to reduce the difficulty of welding construction, avoid radiation damage and dust pollution, and reduce labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

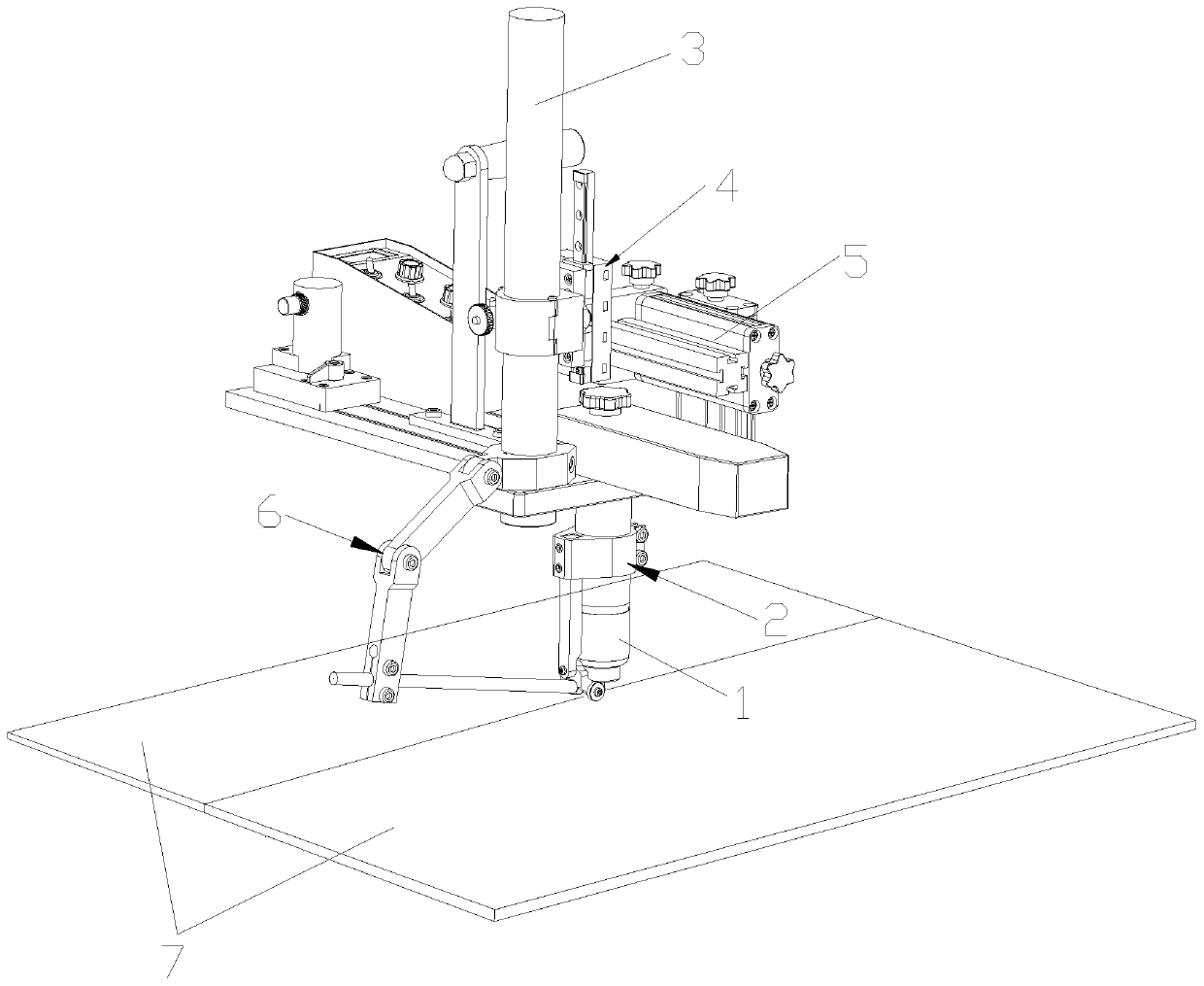

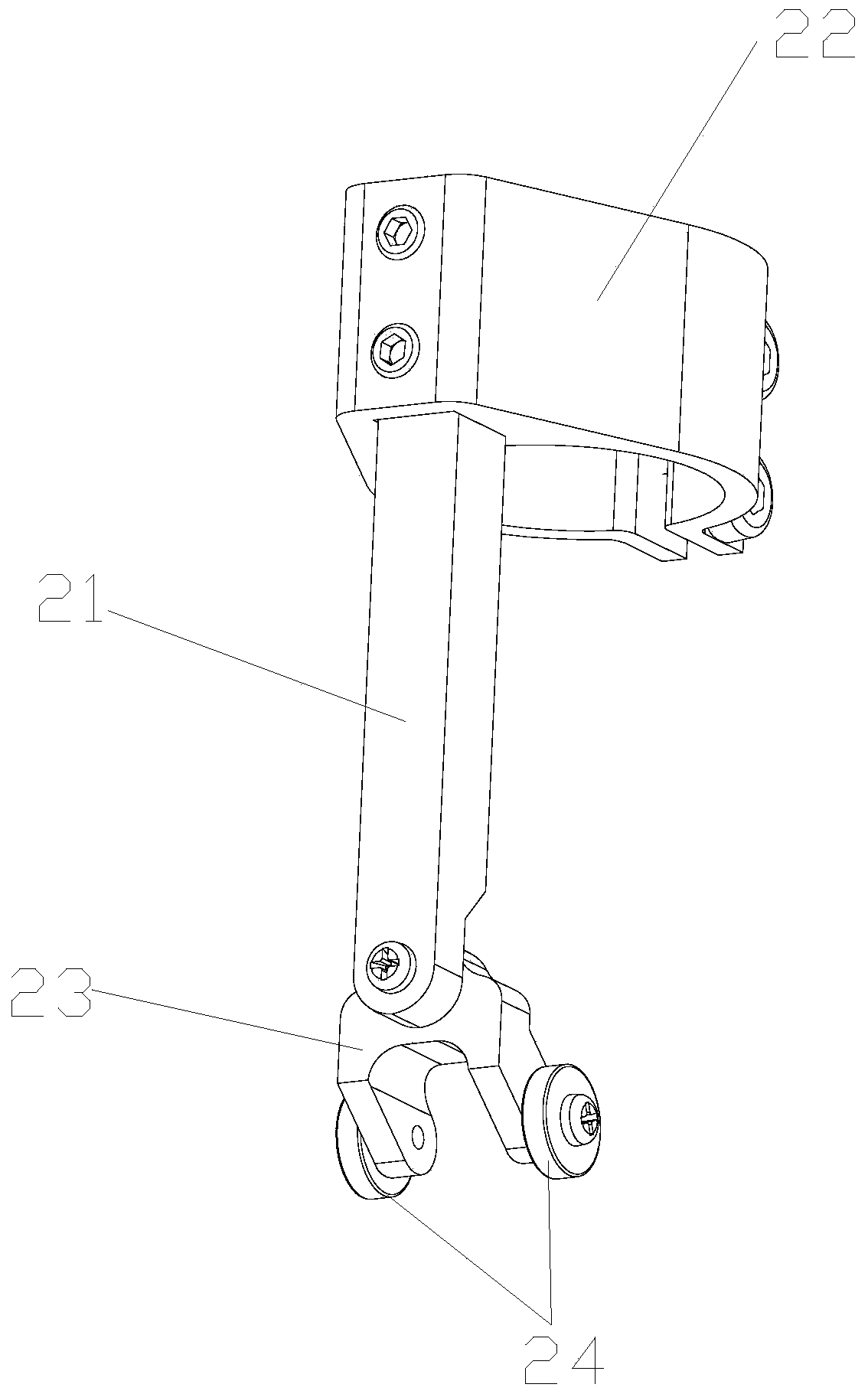

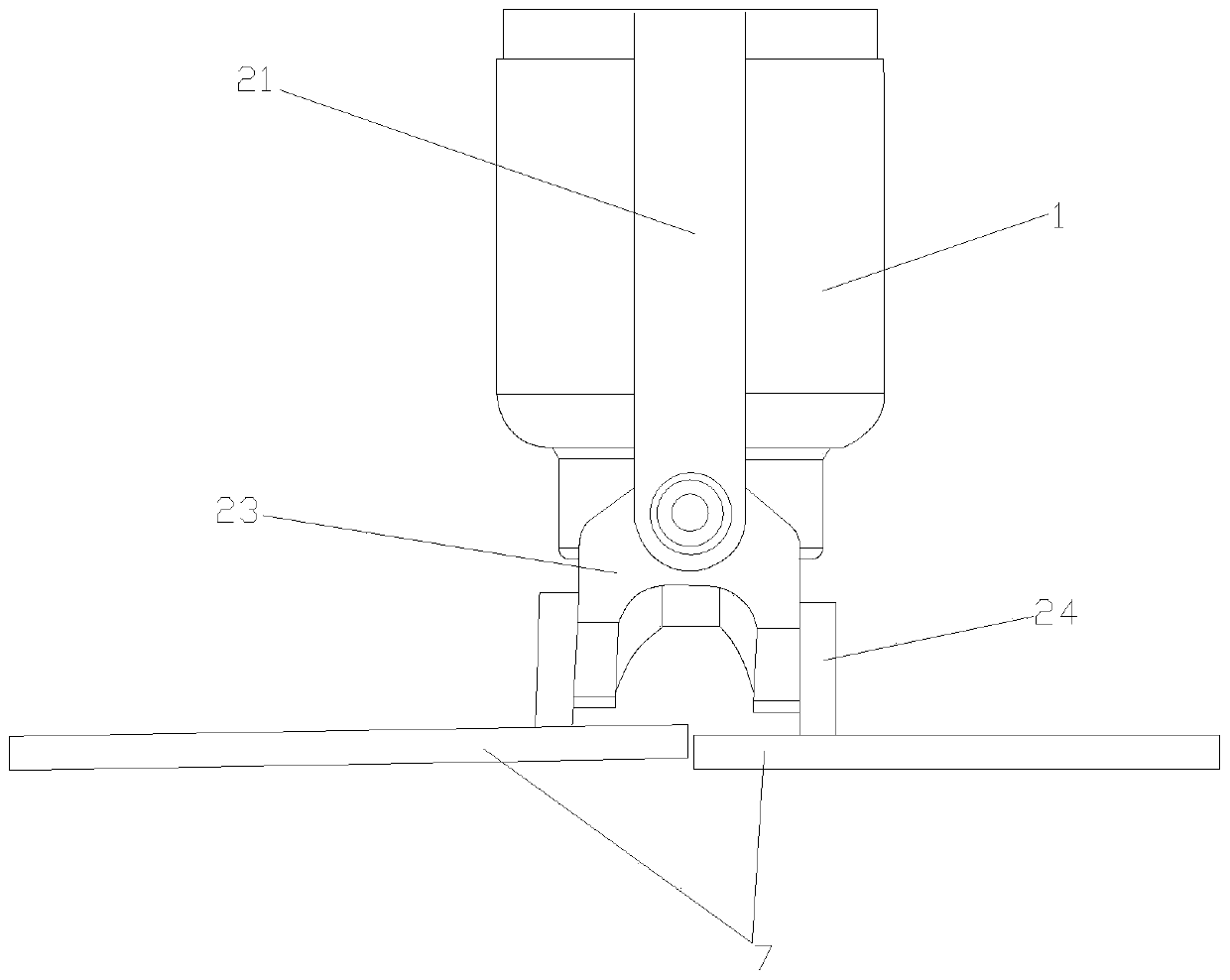

[0027] Such as figure 1 As shown, the present embodiment provides a device for self-adaptive adjustment of the height of the TIG welding torch, including a height-fixing mechanism 2 for fixing the TIG welding torch 1, the upper part of the height-fixing mechanism 2 is provided with a welding torch installation shaft 3, the The welding torch installation shaft 3 is slidingly connected with the welding trolley 5 through a sliding adjustment mechanism 4 , and the lower end of the welding torch installation shaft 3 is provided with a wire feeding mechanism 6 for feeding welding wire to the TIG welding torch 1 .

[0028] During the welding construction process, when the welding trolley 5 drives the TIG welding torch 1 to move forward, the device can not only automatically adjust the TIG welding torch 1 and welding The constant height of the center of the seam can also ensure the mutual cooperation between the wire feeding mechanism 6 and the welding torch, ensure the welding qualit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com